So, you’re curious about what a half nut on a lathe is? Well, you’ve come to the right place!

Imagine you’re working on a lathe—a machine used to shape materials like wood or metal. Now, picture a little part called the half nut. It may sound strange, but it’s actually an essential component of the lathe.

The half nut is a small but mighty gear that helps control the movement of the carriage—the part that holds the cutting tool. Without it, the lathe wouldn’t be able to perform precise and accurate cuts. Exciting stuff, isn’t it? Let’s delve deeper into how this nifty device works!

Understanding the Half Nut on a Lathe: A Comprehensive Guide

When it comes to using a lathe, one essential component that plays a crucial role in its operation is the half nut. But what exactly is a half nut on a lathe? In this in-depth guide, we will explore the purpose, function, and benefits of a half nut, as well as provide tips on how to use it effectively. Whether you’re a beginner or an experienced machinist, this article will take you through everything you need to know about this important feature.

The Role of the Half Nut

The half nut on a lathe is a key component of the threading mechanism. It is responsible for engaging and disengaging the lead screw, which controls the longitudinal movement of the carriage. By properly engaging the half nut, you can initiate the threading process, allowing the lathe to cut accurate and precise threads on the workpiece. Without the half nut, it would be nearly impossible to create threads on a lathe.

In simpler terms, the half nut acts as a clutch that connects the lead screw to the carriage. When engaged, it locks the carriage, allowing for synchronized movement with the lead screw. This synchronization is crucial for producing threads with consistent pitch and depth. Once the threading process is complete, the half nut can be disengaged, allowing the carriage to move freely along the bed of the lathe.

The half nut is typically made of hardened steel to withstand the high forces and pressures exerted during threading. It is precision-machined to ensure a snug fit with the lead screw, minimizing any unwanted play or backlash. A smooth engagement and disengagement of the half nut are vital for achieving accurate thread profiles and preventing damage to the workpiece or the lathe itself.

Using the Half Nut: Step-by-Step Guide

Now that we understand the importance of the half nut, let’s dive into how to effectively use it on a lathe. Here is a step-by-step guide:

Step 1: Align the Half Nut

Before threading, ensure that the half nut is aligned and positioned correctly. It should be aligned with the lead screw in a way that allows for easy engagement and disengagement. Make any necessary adjustments to ensure a smooth operation.

Step 2: Engage the Half Nut

With the workpiece mounted securely and the lathe set to the desired thread pitch, engage the half nut by turning the half nut lever to the “on” position. This will lock the carriage to the lead screw and enable synchronized movement. Take note of any feed or spindle direction settings as per your lathe’s specifications.

Step 3: Start the Threading Process

With the half nut engaged, you can start the threading process. Use the handwheel or power feed mechanism to move the carriage along the bed of the lathe. The lead screw will dictate the rate of movement and the pitch of the threads. Take care to ensure smooth and consistent movement to achieve accurate threads.

Step 4: Disengage the Half Nut

Once the desired length of thread is cut, it’s time to disengage the half nut. This will allow the carriage to move freely without any connection to the lead screw. Make sure the half nut lever is turned to the “off” position to ensure a clean disengagement. You can now move the carriage back to the starting position to prepare for the next threading operation or any other lathe processes.

By following this step-by-step guide, you’ll be able to effectively use the half nut on a lathe and master the art of threading. Remember to practice and familiarize yourself with the specific controls and features of your lathe, as they may vary based on the make and model.

Benefits of Using a Half Nut on a Lathe

1. Precision and Accuracy

Utilizing the half nut ensures precise and accurate thread cutting on a lathe. By engaging the half nut, you create a direct link between the lead screw and the carriage, allowing for synchronized movement. This synchronization eliminates any errors or inconsistencies that may occur from manual manipulation, resulting in threads with consistent pitch, depth, and profile.

2. Increased Efficiency

The half nut mechanism enables efficient and time-saving threading operations. Once engaged, the carriage will automatically follow the lead screw, eliminating the need for constant manual adjustment and realignment. This allows you to focus on other aspects of the machining process, increasing overall productivity.

3. Versatility

The half nut is compatible with various types of threads and thread pitches. Whether you’re cutting metric or imperial threads, fine or coarse, the half nut can accommodate a wide range of thread profiles. This versatility makes it a valuable tool for machinists working on different projects and applications.

4. Safety

Engaging the half nut provides a secure connection between the lead screw and the carriage, ensuring safe and controlled movement during the threading process. This reduces the risk of accidents and injuries that may result from improper thread cutting techniques or sudden movements of the carriage.

5. Consistency

Using the half nut consistently throughout the threading process helps maintain a consistent pitch and depth of threads. This consistency is crucial, especially when working on projects that require precise thread tolerances or when threading multiple parts that need to fit together seamlessly.

Tips for Using the Half Nut

1. Lubrication

Regularly lubricate the half nut and the lead screw to minimize friction and ensure smooth engagement and disengagement. This will prolong the life of the components and enhance the performance of the threading mechanism.

2. Test Cuts

Before cutting threads on your final workpiece, it’s advisable to make test cuts on a scrap or sacrificial piece of material. This will allow you to verify the settings, thread pitch, and overall quality of the threads before working on your actual project.

3. Depth of Cut

When using the half nut, avoid taking deep cuts in a single pass. Instead, make multiple shallow passes to gradually achieve the desired thread depth. This will prevent excessive strain on the half nut and ensure a smoother and more accurate threading process.

By keeping these tips in mind and practicing with the half nut, you’ll improve your threading skills and achieve excellent results on your lathe.

Frequently Asked Questions (FAQs)

Q: Can I thread on a lathe without using the half nut?

A: While it is technically possible to manually cut threads on a lathe without using the half nut, it is highly impractical and rarely done. The half nut provides precise synchronization between the carriage and the lead screw, resulting in accurate and consistent threads. Attempting to manually create threads without the half nut would require constant adjustment and would likely yield poor results.

Q: Why is it called a “half nut”?

A: The term “half nut” is derived from the fact that the nut used in the threading mechanism is split into two halves. These halves come together to form a complete nut when engaged with the lead screw, hence the name “half nut.”

Q: Are there any alternatives to using a half nut for threading?

A: While the half nut is the standard method for threading on a lathe, there are some alternative methods available. One such method is using a thread-cutting attachment, which allows for more intricate and specialized thread cutting. However, the half nut remains the most commonly used method due to its simplicity and effectiveness.

Conclusion

It’s clear that the half nut plays a vital role in the threading process on a lathe. Understanding its purpose, function, and proper usage is essential for any machinist looking to produce accurate and high-quality threads. By following the step-by-step guide, considering the benefits, and implementing the tips provided, you’ll be well on your way to mastering the art of using the half nut on a lathe.

Key Takeaways: What is a Half Nut on a Lathe?

- A half nut is a component used in lathes to engage or disengage the leadscrew.

- It helps control the movement of the carriage and tool along the lathe bed.

- The half nut locks onto the leadscrew, allowing for precise threading operations.

- When engaged, the half nut meshes with the threads on the leadscrew.

- When disengaged, the half nut releases the leadscrew, enabling free movement of the carriage.

Frequently Asked Questions

When working with a lathe, the half nut is a critical component of the machine. It plays a crucial role in the threading process. Below are some common questions and answers related to the half nut on a lathe:

Question 1: How does the half nut work on a lathe?

Answer: The half nut on a lathe is a component that engages with the lead screw, which is responsible for controlling the movement of the carriage. When threading, the half nut is engaged with the lead screw, causing the carriage to move along the bed. This allows the cutting tool to create the desired threads on the workpiece. The half nut disengages when not in use, allowing for free movement of the carriage.

It is important to note that the half nut should only be engaged when threading and not during other operations to avoid unnecessary wear and tear on the machine.

Question 2: What are the benefits of using a half nut on a lathe?

Answer: The half nut on a lathe offers several benefits. Firstly, it enables precise and accurate threading. By engaging the half nut with the lead screw, the user can control the movement of the carriage, resulting in well-defined threads on the workpiece. Additionally, the half nut provides stability during the threading process, reducing the likelihood of errors or imperfections.

Furthermore, the half nut allows for the creation of different thread sizes and pitches, making it a versatile tool in machining. By adjusting the gearing and engaging the appropriate half nut, the operator can produce threads of varying specifications with ease.

Question 3: Can I operate a lathe without a half nut?

Answer: Operating a lathe without a functioning half nut can be challenging, especially when it comes to threading. The half nut plays a crucial role in controlling the movement of the carriage and creating precise threads. Without the half nut, it would be difficult to achieve accurate and consistent threading results.

If your lathe’s half nut is damaged or missing, it is crucial to get it repaired or replaced before attempting to thread or perform other operations that require its functionality.

Question 4: How do I maintain and clean the half nut on a lathe?

Answer: Proper maintenance and cleaning of the half nut are essential for its smooth operation and longevity. Regularly inspect the half nut for any signs of wear or damage. If necessary, clean it using a mild cleaning agent and a soft brush, ensuring that you remove any debris or dirt that may have accumulated.

Additionally, lubrication is crucial to reduce friction and wear. Apply a suitable lubricant to the half nut and the lead screw to maintain smooth engagement and movement. Regularly check for adequate lubrication and reapply as needed.

Question 5: Can I replace the half nut on a lathe myself?

Answer: While it is possible to replace the half nut on a lathe yourself, it is recommended to consult a professional or an experienced lathe technician. Replacing the half nut involves dismantling certain parts of the lathe and ensuring proper alignment and engagement with the lead screw. If not done correctly, it can lead to poor threading performance or damage to the lathe.

If you are unsure about replacing the half nut yourself, it is best to seek guidance from a knowledgeable individual or reach out to a lathe repair service for assistance.

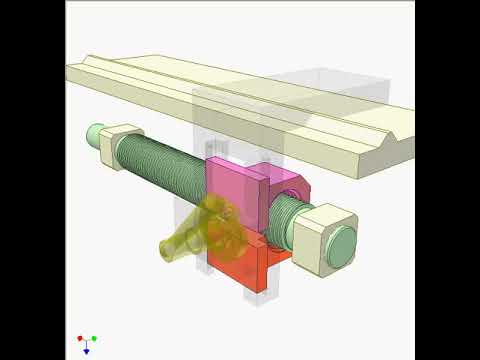

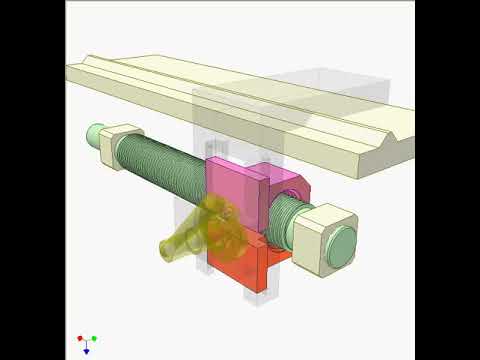

Engaging a half nut…..made easier

Summary

So, what’s a half nut on a lathe? It’s a part that helps the lathe move smoothly. The half nut is like a friend for the lathe’s lead screw. It opens and closes, gripping onto the lead screw to make the lathe move forward or backward. When the half nut is closed, it locks onto the lead screw, allowing the lathe to turn the material. And when it’s open, the lathe can move freely. So, the half nut is a crucial part of the lathe that makes it work properly.

But why is it called a “half” nut? Well, that’s because it only covers half of the lead screw. It has a matching groove on the inside that fits over the lead screw. This way, when the half nut is closed, it can engage with the lead screw, but when it’s open, it moves out of the way. So, the half nut helps control the movement of the lathe and is an important component for machining.