Have you ever wondered if you can make a lathe with a lathe? Well, you’re in the right place to find out! In this article, we’ll explore the fascinating world of lathes and whether it’s possible to create one using another lathe. So, get ready to dive into the world of machining and discover the creative possibilities that lie within!

When it comes to crafting and building things, creativity knows no bounds. And the idea of making a lathe with a lathe is no exception. It’s like a puzzle within a puzzle, where you use one tool to create another. Intriguing, isn’t it? So, let’s unravel this mystery and see if it’s really feasible to make a lathe using just your trusty lathe.

Whether you’re a budding machinist or simply enjoy exploring hands-on projects, the concept of making a lathe with a lathe is both exciting and thought-provoking. So, let’s embark on this journey together and uncover the possibilities that await. Get ready to unravel the wonders of lathe-ception!

Discover how you can create inventive projects by utilizing your lathe to build another lathe! While it may sound unusual, it’s possible to repurpose your lathe for this purpose. With a little creativity and the right tools, you can transform your lathe into a functional lathe. By repurposing parts and making adjustments, you’ll be able to enhance your woodworking skills and take your craftsmanship to new heights!

Can You Make a Lathe with a Lathe?

When it comes to woodworking and metalworking, a lathe is an essential tool. It allows craftsmen to shape and smooth materials, creating intricate designs and precision parts. But have you ever wondered if it’s possible to make a lathe using another lathe? In this article, we will explore the concept of making a lathe with a lathe, the benefits and challenges it presents, and some tips for those brave enough to take on this DIY project.

1. Understanding the Basics

Before diving into the process of making a lathe with a lathe, it’s important to understand the basics of how a lathe works. A lathe is a machine tool that rotates a workpiece against a cutting tool to shape and refine it. The workpiece is clamped securely and rotated at various speeds while the cutting tool is maneuvered by the operator to remove material and create the desired shape. This rotational movement is the key characteristic of a lathe and provides the foundation for building a lathe with a lathe.

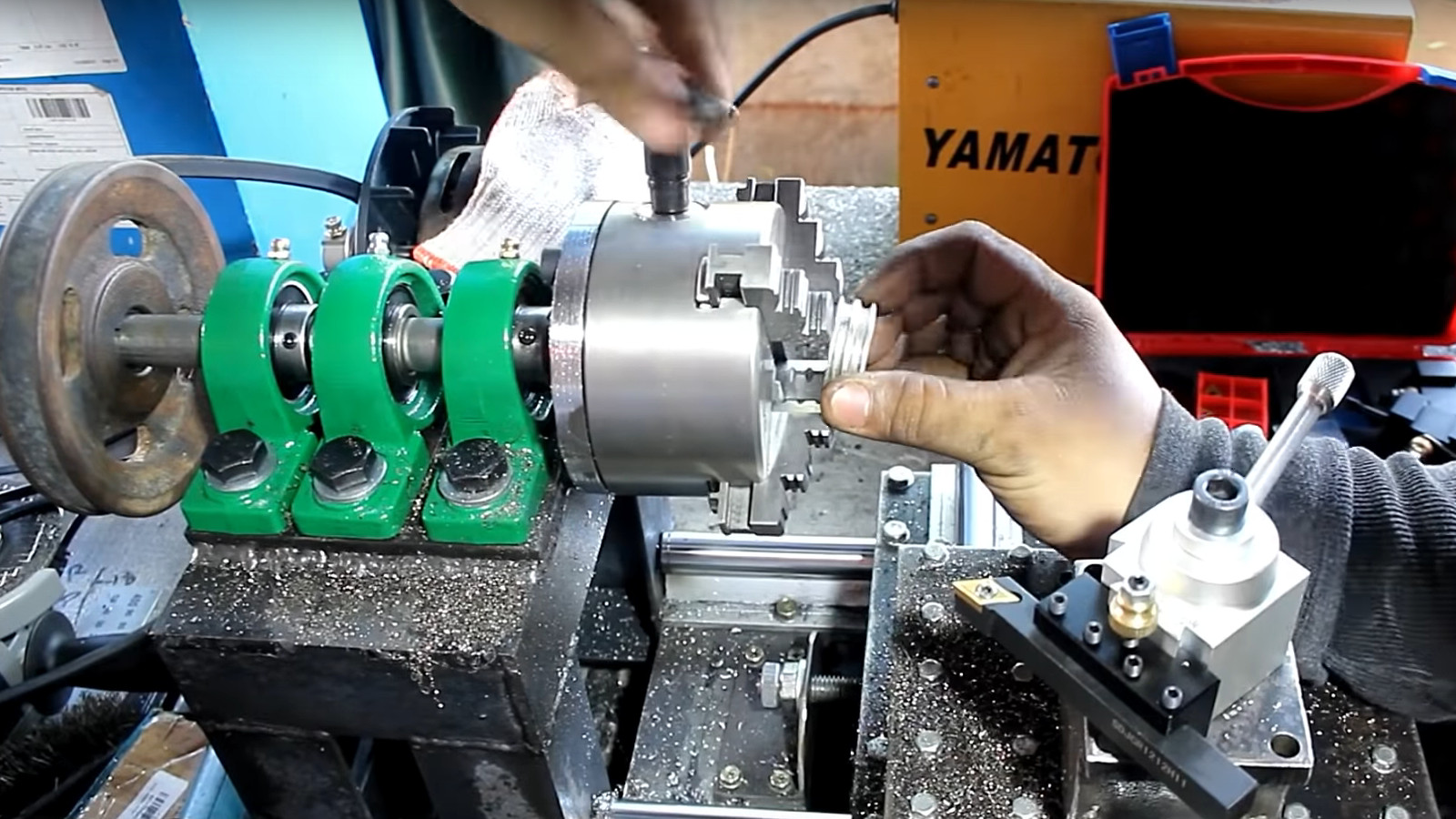

Building a lathe with a lathe involves using the existing lathe to create the necessary components and mechanisms required for a functional lathe. This can range from creating the bed, headstock, tailstock, and tool rest to fabricating the threading mechanism, motor mount, and drive system. It requires careful planning, precise measurements, and a good understanding of the principles of lathe construction.

To build a lathe with a lathe, you will need a lathe with enough capacity and capabilities to handle the workload. It should have a sturdy bed, a reliable motor, and the necessary accessories to create the components needed for the new lathe. You will also need a solid understanding of lathe operations, including the use of cutting tools, tool rests, and lathe attachments. With these fundamentals in place, you can begin the process of making a lathe with a lathe.

2. The Benefits and Challenges

Building a lathe with a lathe offers several benefits, including the ability to customize the design to meet your specific needs and the satisfaction of creating a functional tool from scratch. It also allows for cost savings as the main lathe is already available for use. By building your own lathe, you can incorporate features and modifications that are not commonly found in off-the-shelf machines.

However, there are also significant challenges when it comes to making a lathe with a lathe. Firstly, it requires a certain level of skill and knowledge in metalworking and woodworking. The process involves complex machining and fabrication techniques, and any mistakes or miscalculations can impact the functionality and safety of the lathe. Additionally, it can be time-consuming and labor-intensive, requiring patience and attention to detail throughout the construction process.

Another challenge is the limited capacity and capabilities of the original lathe. Depending on the size and power of the lathe used to build the new one, there may be limitations on the size and complexity of the components that can be produced. This can impact the range of projects that can be undertaken using the homemade lathe.

3. Tips for Making a Lathe with a Lathe

If you’re ready to take on the challenge of making a lathe with a lathe, here are some tips to help you along the way:

- Research and gather information: Before starting the project, thoroughly research lathe construction and gather any necessary plans or blueprints to guide you in the building process.

- Invest in quality materials: Use high-quality materials for the construction of the new lathe to ensure durability and longevity.

- Take precise measurements: Accurate measurements are crucial in ensuring that the components fit together properly and that the lathe functions as intended.

- Seek guidance from experienced craftsmen: Reach out to experts in lathe construction for advice and guidance on the process.

- Don’t rush the process: Building a lathe with a lathe takes time and careful attention to detail. Take your time to ensure that each step is completed accurately.

- Test and refine: Once the lathe is built, test it thoroughly to identify any issues or areas for improvement. Make adjustments and refinements as needed.

- Stay safe: Always prioritize safety when working with machinery. Wear appropriate protective gear and follow safety guidelines to prevent accidents or injuries.

Additional Information on Making a Lathe with a Lathe

The DIY Approach: Building Your Own Lathe

A DIY lathe can be an exciting project for woodworking and metalworking enthusiasts. By building your own lathe, you have the opportunity to customize the design, incorporate specific features, and save money compared to purchasing a pre-made machine. However, building a lathe from scratch requires a considerable amount of knowledge, skill, and access to the right tools and materials.

Exploring Lathe Components and Functionality

Before attempting to make a lathe with a lathe, it’s essential to have a thorough understanding of the various components and their functions in a lathe. From the bed and headstock to the tool rest and tailstock, each part plays a vital role in the lathe’s overall operation. Knowing how these components work together will help you design and construct your homemade lathe effectively.

Supplementing Your Lathe with Attachments and Accessories

In addition to building a lathe from scratch, you can also enhance the capabilities of a basic lathe by incorporating various attachments and accessories. These can include additional tool rests, faceplates, chucks, and specialized centers, among others. By expanding your lathe’s functionality, you can tackle a wider range of projects and achieve more precise results.

In summary, while it is technically possible to make a lathe with a lathe, it is a complex and challenging endeavor that requires a strong foundation of knowledge, skill, and experience in metalworking and woodworking. The process offers both benefits and challenges, including customization opportunities, cost savings, and the satisfaction of building your own tool. By following best practices, seeking guidance from experts, and prioritizing safety, you can increase your chances of success in creating a functional lathe using another lathe. Good luck on your lathe-building journey!

Can You Make a Lathe with a Lathe?

- Yes, you can make a lathe with a lathe.

- A lathe is a machine used for shaping wood or metal.

- With a lathe, you can create various parts and components.

- Using a lathe, you can also build your own lathe.

- However, it may require additional materials and knowledge.

Frequently Asked Questions

Are you curious about making a lathe with another lathe? Here are some commonly asked questions about this fascinating topic!

1. Is it possible to create a lathe using another lathe?

While it may seem counterintuitive, it is indeed possible to make a lathe using another lathe. This process is known as “lathe duplicating” or “lathe replication.” Essentially, it involves using an existing lathe to create the necessary components for a new lathe.

The initial lathe is used to turn and shape the various parts required for the new lathe, such as the bed, the headstock, and the tailstock. Once these components are made, they can be assembled together to build a functional lathe. It’s like a lathe giving birth to another lathe!

2. What are the advantages of making a lathe with a lathe?

Making a lathe with another lathe brings several advantages. Firstly, it allows for the replication of an existing lathe design, ensuring consistency and accuracy in the new machine. Additionally, this method can be cost-effective, especially if the required materials and components are readily available.

Another advantage is the ability to customize the new lathe to meet specific needs and preferences. By using an existing lathe as a template, modifications and improvements can be made to suit individual requirements. This flexibility makes it an attractive option for machinists and hobbyists who want a lathe tailored to their unique needs.

3. What skills and knowledge are required to make a lathe with a lathe?

Making a lathe with a lathe requires a solid understanding of lathe operation and machining principles. Knowledge of how to operate and control a lathe is essential, as it is the primary tool used in the replication process. Machinists undertaking this task should also have experience in turning and shaping metal or other materials.

Additionally, expertise in reading and interpreting engineering drawings and specifications is crucial to ensure accurate replication. A good grasp of measurement techniques and precision machining is also necessary to create the components with the required precision. Patience, attention to detail, and problem-solving skills are other valuable attributes.

4. Can a homemade lathe be as accurate as a commercially manufactured one?

It is possible to achieve a high level of accuracy with a homemade lathe, similar to commercially manufactured lathes. However, it depends on various factors such as the skill level of the machinist, the quality of the materials used, and the precision of the measurements taken during the replication process.

With careful attention to detail, proper calibration, and the use of accurate measurement tools, a homemade lathe can produce accurate results. It is essential to take the time to ensure all components are made to the required specifications and assembled correctly for optimal performance.

5. Are there any limitations or challenges when making a lathe with a lathe?

Making a lathe with a lathe is not without its challenges. One of the main limitations is the size capacity of the existing lathe. The dimensions of the components that can be replicated are limited by the swing capacity and distance between centers of the primary lathe.

Another challenge is the availability of suitable materials and the precision required in creating the components. Obtaining or fabricating high-quality parts, such as the spindle, may pose challenges if specific materials or specialized tools are required. Additionally, ensuring the alignment and accuracy of the replicated parts during assembly can be a meticulous process that requires patience and attention to detail.

How I built my HOMEMADE Lathe!

Summary

You can’t make a lathe with a lathe because a lathe is a specific machine used for shaping materials like wood or metal. It’s not designed to build other lathes. The components needed to construct a lathe are different from what a lathe can produce. So, you can’t use a lathe to make a lathe.

However, if you want to build a lathe, you can purchase or find the necessary parts and assemble them using various tools. There are DIY plans available online, and you can also learn from experienced individuals. So, while you can’t make a lathe with a lathe, you can build one with the right knowledge, resources, and tools.