Can you use HSS drill bits for concrete? If you’ve ever wondered about this, you’ve come to the right place! Many people are unsure if they can use high-speed steel (HSS) drill bits for drilling into concrete. Well, let me tell you, it’s a valid question!

Drilling into concrete is a different ball game compared to drilling into wood or metal. The hard and dense nature of concrete requires special tools. HSS drill bits are commonly used for softer materials like wood or metal, but can they handle concrete? Let’s find out!

Concrete is a tough nut to crack, and it requires a drill bit specifically designed for its hardness and abrasive properties. While HSS drill bits may work to some extent, they are not the most ideal choice for concrete drilling. So, stick around as we explore the suitable options for drilling into concrete and discover the right tools for the job!

HSS drill bits are typically designed for drilling through metal, so using them for concrete can be challenging. While they may work for softer concrete, it’s recommended to use carbide-tipped masonry drill bits for best results. These bits are specifically designed for concrete and will provide better performance and durability. Using the right tool for the job ensures easier drilling and prevents damage to your drill bits.

Can You Use HSS Drill Bits for Concrete?

Concrete is a sturdy and durable material used in various construction projects. When it comes to drilling holes in concrete, it may seem challenging to find the right drill bit for the job. One common question that arises is whether High-Speed Steel (HSS) drill bits can be used for drilling concrete. In this article, we will explore the suitability of HSS drill bits for concrete drilling and provide you with essential information to make an informed decision.

The Basics of HSS Drill Bits

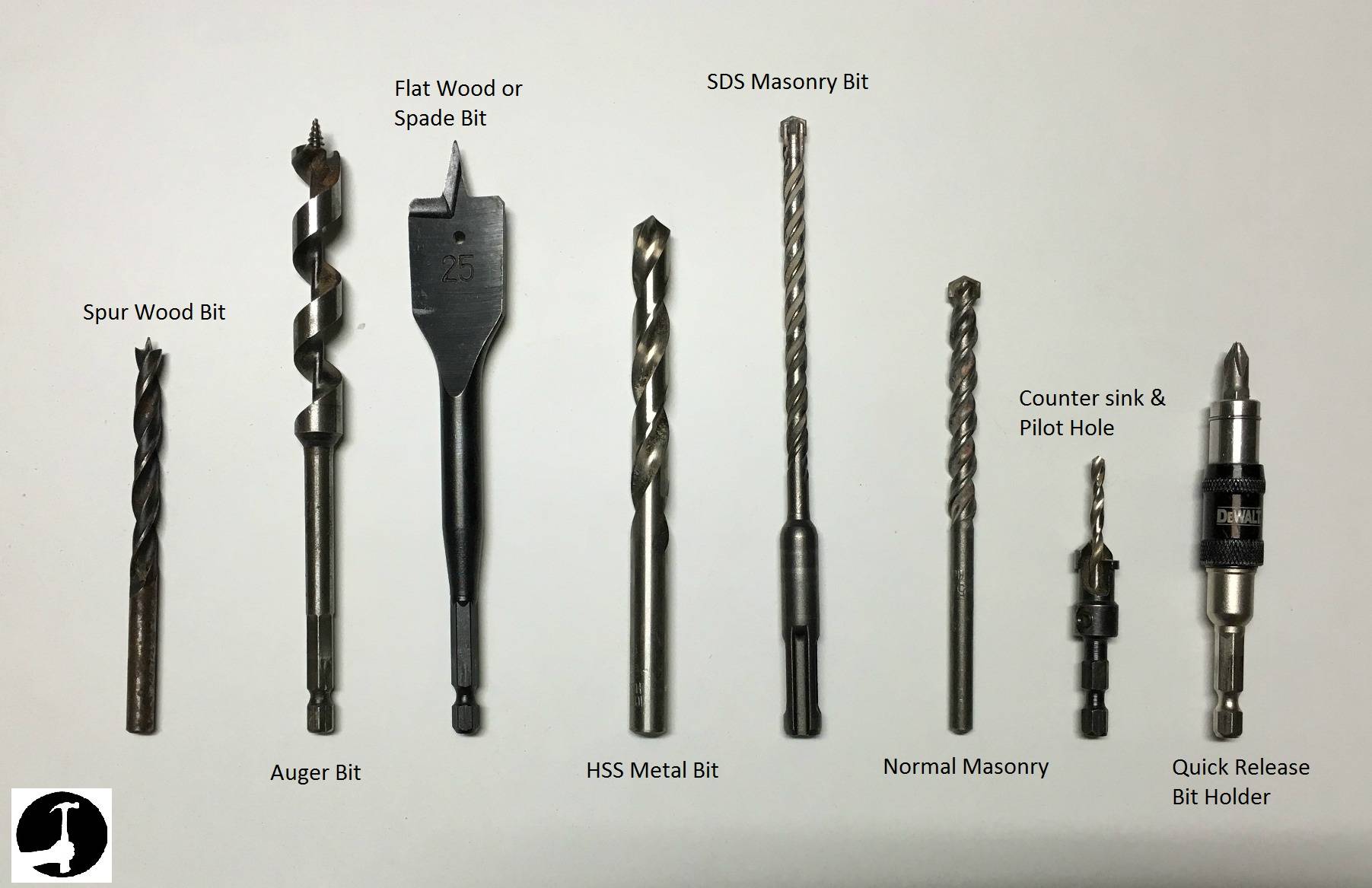

High-Speed Steel (HSS) drill bits are versatile tools commonly used for drilling holes in materials such as wood, plastic, and metal. They are made from a durable and heat-resistant steel alloy, allowing them to withstand high speeds and temperatures generated during drilling. HSS drill bits are available in various sizes and shapes to meet different drilling needs.

One of the distinct features of HSS drill bits is their sharp cutting edges, which facilitate efficient material removal. However, when it comes to drilling concrete, the properties of the material can pose challenges that HSS drill bits may not be equipped to handle. Let’s explore why.

The Challenges of Using HSS Drill Bits for Concrete

Concrete is a dense and abrasive material composed of sand, gravel, cement, and water. Its composition and hardness make it challenging to drill through without the right tool. While HSS drill bits are excellent for softer materials like wood and plastic, they may struggle to penetrate concrete effectively. Here are some challenges you may encounter when using HSS drill bits for concrete drilling:

- Wear and Tear: Concrete is abrasive and can cause rapid wear and dulling of HSS drill bits. The cutting edges may wear down quickly, reducing their efficiency and lifespan.

- Heat Buildup: Concrete drilling generates a significant amount of heat due to friction. HSS drill bits are not specifically designed to handle excessive heat, which can lead to overheating and potential damage.

- Lack of Impact Resistance: Concrete drilling often requires impact or hammering action to break through the material. HSS drill bits lack the necessary impact resistance, making them less effective in this regard.

Considering these challenges, it is generally not recommended to use HSS drill bits for concrete drilling. However, there are alternative options available that are better suited for this specific task.

Alternatives to HSS Drill Bits for Concrete Drilling

If you need to drill holes in concrete, it is advisable to use drill bits specifically designed for masonry and concrete. Here are a few suitable alternatives to HSS drill bits:

- Carbide-Tipped Masonry Drill Bits: These drill bits feature a carbide tip that is highly resistant to the abrasiveness of concrete. They can withstand the heat generated during drilling and offer superior performance and durability.

- Diamond-Tipped Drill Bits: Diamond-tipped drill bits are the ultimate choice for drilling through concrete. The diamond coating on the tip allows for efficient cutting and excellent longevity.

- Hammer Drill Bits: Hammer drill bits are designed for use with hammer drills, which provide the necessary impact force for drilling into concrete. These bits are often made from carbide or have carbide inserts for enhanced durability.

By opting for these specialized drill bits, you can ensure efficient and successful drilling in concrete without compromising the performance and lifespan of your tools.

Factors to Consider When Choosing a Drill Bit for Concrete

When selecting a drill bit for concrete, there are some essential factors to consider. These factors will help you choose the right tool for the job and ensure optimal performance. Here are a few key considerations:

1. Material:

Ensure that the drill bit you choose is specifically designed for drilling into concrete or masonry materials. Using the wrong type of drill bit can lead to inefficient drilling and damage to the bit.

2. Size:

Consider the required hole size and choose a drill bit that matches your desired diameter. Using a drill bit that is too small or too large may result in unsatisfactory results.

3. Shank Type:

Check the shank type of the drill bit to ensure compatibility with your drill. Common shank types include round shank, hex shank, and SDS shank. Make sure the shank matches your drill’s chuck.

4. Quality:

Invest in high-quality drill bits to ensure longevity, performance, and safety. Cheap and low-quality drill bits may wear down quickly, leading to poor results and potential tool damage.

5. Application:

Different drill bits are designed for specific applications within concrete drilling. Consider whether you need a drill bit for general drilling purposes, anchor installations, or other specialized tasks.

By carefully considering these factors, you can select the most suitable drill bit for your concrete drilling needs.

Tips for Successful Concrete Drilling

Drilling into concrete can be a challenging task, but with the right tools and techniques, you can achieve successful results. Here are some tips to help you drill into concrete effectively:

1. Mark the drilling location:

Before drilling, use a pencil or marker to clearly mark the exact spot where you need to drill. This will ensure accuracy and prevent unnecessary drilling.

2. Use a hammer drill:

For efficient concrete drilling, invest in a hammer drill. Hammer drills provide the necessary impact force to break through the dense material, making the process quicker and easier.

3. Start with a smaller pilot hole:

For larger holes, it is recommended to start with a smaller pilot hole. This will help guide the larger drill bit and prevent it from wandering off course.

4. Apply steady pressure:

When drilling into concrete, apply constant and steady pressure to maintain a consistent drilling speed. Avoid excessive force, as it can lead to overheating or even breakage of the drill bit.

5. Use water for cooling:

If you notice excessive heat during drilling, you can periodically spray water on the drill bit to cool it down. This will help prolong the life of the drill bit and prevent overheating.

By following these tips and using the right drill bit, you can successfully drill holes in concrete and complete your construction or DIY projects with ease.

Conclusion

When it comes to drilling holes in concrete, it is important to use the right tools for the job. While High-Speed Steel (HSS) drill bits are versatile and suitable for various materials, they are not the best choice for concrete drilling. Concrete is a dense and abrasive material that requires specialized tools such as carbide-tipped masonry drill bits or diamond-tipped drill bits.

By selecting the right drill bit for concrete drilling and following the recommended tips, you can achieve efficient and successful results. Remember to prioritize safety, invest in high-quality drill bits, and use appropriate techniques to ensure a smooth drilling experience. With the right tools and knowledge, you can tackle any concrete drilling project with confidence.

Can You Use HSS Drill Bits for Concrete?

When it comes to drilling into concrete, it’s not recommended to use HSS (High-Speed Steel) drill bits. Here’s why:

- HSS drill bits are designed for drilling through softer materials like wood and metal, not concrete.

- Concrete is a dense and hard material that requires a more robust drill bit.

- Using HSS drill bits on concrete can result in dulling or even breaking the bit.

- For drilling into concrete, it’s best to use masonry drill bits that are specifically designed for the task.

- Masonry drill bits have a special carbide tip that can withstand the tough nature of concrete.

Remember, always use the right tool for the job to ensure safe and effective drilling.

Frequently Asked Questions

Welcome to our FAQ section where we answer your questions about using HSS drill bits for concrete. Here, you’ll find valuable information on whether or not HSS drill bits are suitable for concrete projects. Read on to learn more!

Q1: Can HSS drill bits be used for drilling into concrete?

A1: While HSS (High-Speed Steel) drill bits are versatile and can work with various materials, they are not the best choice for drilling into concrete. HSS drill bits are designed primarily for drilling into softer materials like wood, plastic, and metal. However, when used on concrete, HSS bits tend to overheat quickly and wear out faster due to the hardness and abrasiveness of the concrete. For drilling into concrete, it is recommended to use masonry drill bits specifically designed for the task.

Using the right drill bit for the job is crucial for achieving clean and effective results. So, when undertaking a concrete drilling project, opt for masonry drill bits that are specifically engineered to withstand the demands of drilling through hard materials like concrete, stone, and brick.

Q2: What are masonry drill bits and why are they ideal for concrete?

A2: Masonry drill bits are specifically designed to drill into hard and dense materials like concrete. They are made of specialized carbide or tungsten carbide tips that can withstand the high impact and friction of drilling into hard surfaces. The tip of a masonry drill bit is usually shaped like a spear or chisel, allowing it to penetrate concrete more effectively and prevent slipping or wandering.

The unique design of masonry drill bits allows them to create clean, precise holes in concrete without getting damaged. They are built to endure the challenges posed by concrete, making them the perfect choice for any drilling project involving this material. So, if you need to drill into concrete, it is highly recommended to use masonry drill bits for optimal results.

Q3: Can HSS drill bits be used on smaller concrete drilling projects?

A3: While HSS drill bits are not the best choice for drilling into concrete, they can occasionally be used for smaller concrete drilling projects. If you only need to drill a few small holes or make shallow indentations in the concrete surface, you can try using HSS drill bits. However, keep in mind that using HSS drill bits on concrete may cause the bits to wear out quickly or overheat due to the hardness of the material.

If you do decide to use HSS drill bits for small concrete drilling projects, proceed with caution and take breaks during drilling to prevent overheating. It’s also important to note that the holes created might not be as clean or precise compared to using masonry drill bits. For larger or more critical concrete drilling tasks, it is advisable to invest in proper masonry drill bits to ensure better results and avoid damage to your tools.

Q4: What are the dangers of using HSS drill bits on concrete?

A4: As mentioned earlier, using HSS drill bits on concrete can lead to several risks and issues. Firstly, since HSS drill bits are not designed for drilling into concrete, they can wear out quickly when exposed to the toughness and abrasiveness of the material. This can result in a significant decrease in their drilling performance and lifespan.

Additionally, HSS drill bits can overheat when used on concrete, which can cause the bits to become dull or even break. The excessive heat generated can damage the cutting edges of the drill bits and affect their drilling efficiency. Therefore, it is crucial to avoid using HSS drill bits for concrete drilling to prevent damage to the bits and ensure safer drilling practices.

Q5: Are there any tips for choosing the right drill bits for concrete?

A5: Absolutely! When selecting drill bits for concrete, consider the following tips:

– Look for drill bits specifically designed for masonry or concrete drilling. These are made with materials that can handle the demands of drilling into hard surfaces effectively.

– Check the shank size of the drill bits to ensure compatibility with your drill machine.

– Consider the type of concrete project you’re undertaking (e.g., drilling large holes, anchoring objects, etc.) and choose drill bits accordingly.

– Opt for carbide-tipped or tungsten carbide drill bits for enhanced durability and performance.

By following these tips, you’ll be able to select the right drill bits for concrete and achieve excellent results in your drilling projects.

Summary

Using HSS drill bits for concrete is not recommended because they are not designed for this type of material. Concrete is a hard and abrasive substance, and HSS drill bits are not strong enough to withstand it. They can become dull quickly, causing them to overheat and become less effective. It is best to use carbide-tipped or masonry drill bits specifically made for concrete drilling.

When drilling into concrete, it is important to apply steady pressure and use a slow speed to avoid damaging the bit. Also, it is crucial to wear appropriate safety gear such as safety glasses and gloves to protect yourself. By using the right drill bits and following proper techniques, you can achieve successful and efficient concrete drilling without damaging your tools.