Are you curious about woodworking shops and how big they need to be? Well, you’ve come to the right place! In this article, we’ll explore the ideal size for a woodworking shop. So, if you enjoy working with your hands and creating beautiful things out of wood, keep reading!

Woodworking is a fantastic hobby that allows you to unleash your creativity and craft unique pieces. But before you start setting up your shop, you need to consider the space you’ll need. From the tools and equipment to lumber storage and workbenches, having enough room is crucial for a smooth and efficient woodworking experience.

The size of a woodworking shop can vary depending on various factors, such as the types of projects you plan on tackling, the tools you’ll be using, and your available space. In this article, we’ll delve into these considerations to help you determine just how big your woodworking shop needs to be. So, let’s dive in and discover the perfect-sized shop for your woodworking adventures!

- Analyze your woodworking projects and the tools you’ll need.

- Measure the required space for each tool, workbench, storage, and walkways.

- Consider future expansion needs and potential growth.

- Create a layout plan to optimize space and workflow.

By following these steps, you can determine the perfect size for your woodworking shop.

How Big Does a Woodworking Shop Need to Be?

A woodworking shop is a space where creativity, skill, and craftsmanship come together. It’s a place where woodworkers bring their ideas to life and create beautiful pieces of furniture, cabinetry, and more. But when it comes to building or designing a woodworking shop, one question often arises: how big does it need to be?

While the size of a woodworking shop will vary depending on individual needs and circumstances, there are several factors to consider when determining the ideal size. From the type of projects you plan to undertake to the space required for tools and equipment, it’s essential to find the right balance to ensure a functional and efficient workspace.

The Nature of Woodworking Projects

Woodworking projects come in all shapes and sizes, ranging from small personal crafts to large-scale furniture pieces. The size of your woodworking shop should align with the type of projects you plan to take on. If you prefer working on smaller items, such as intricate carvings or small decorative pieces, a compact workshop may suffice. However, if you envision building large furniture or cabinetry, you’ll need a more spacious area to accommodate the materials and tools needed for these projects.

Additionally, consider the workflow of your projects. If you frequently work on multiple projects simultaneously or require ample space for assembly and finishing work, a larger shop will provide the room and organization necessary to carry out these tasks efficiently.

Tools, Equipment, and Storage

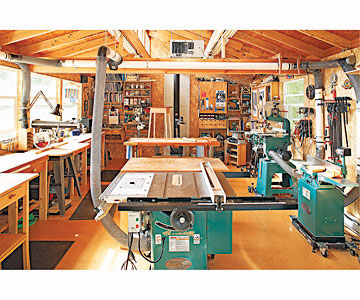

Woodworking involves a myriad of tools and equipment, from power tools like table saws and routers to smaller hand tools such as chisels and planes. The size of your woodworking shop should allow for proper storage and accessibility of these tools. Investing in sturdy tool cabinets, wall-mounted organizers, and vertical storage solutions can help maximize space and keep your tools organized and easily accessible.

Furthermore, consider the size and dimensions of your larger woodworking equipment. If you own large machinery like band saws or planers, you’ll need sufficient space to set them up and move around comfortably. Take into account the clearances required for these tools, as well as any additional space needed for dust collection systems or workbenches.

Workspace and Safety Considerations

Adequate workspace is crucial for any woodworking endeavor. You need sufficient room to maneuver, cut, shape, and assemble your pieces. It’s important to have enough bench space to spread out your materials, tools, and projects without feeling cramped or restricted.

Additionally, don’t forget to consider safety in your woodworking shop. Leave enough room between workstations to prevent accidents and allow for efficient movement. Install proper ventilation to control dust and fumes, and ensure adequate lighting to have a clear view of your workspace.

Budget and Available Space

One of the key determinants of the size of your woodworking shop is your budget and the available space. Building or renovating a workshop can be costly, so it’s important to establish a budget early on and stick to it. Consider the cost of materials, tools, and any necessary renovations or additions to create a functional and comfortable workspace.

If you have limited space, careful planning and organization can help you optimize every square inch. Utilize vertical space, install folding or mobile workbenches, and incorporate storage solutions that utilize underutilized areas, such as wall space or overhead storage racks.

Flexibility and Future Growth

When designing your woodworking shop, it’s important to consider future growth and allow for flexibility. Your woodworking journey may take you in new directions or require additional space or equipment. It’s wise to plan for expansion or reconfiguration in case your needs change over time.

Consider leaving room for future additions, such as new tools or machinery, as well as the possibility of growing your business or taking on larger projects. This foresight will save you from the hassle of outgrowing your shop too quickly and having to make major renovations or relocations.

Creating the Optimal Woodworking Shop

Building the perfect woodworking shop involves finding the right balance between the space you have available, your budget, and the scale and nature of your projects. Consider the size and type of projects you wish to undertake, the tools and equipment you own, and the workspace and safety considerations that are essential for a functional and enjoyable woodworking experience.

By carefully planning and designing your woodworking shop, you’ll create a space that inspires creativity, allows for efficient workflow, and provides the room and organization necessary to bring your woodworking dreams to life.

Choosing the Right Location

The location of your woodworking shop plays a significant role in its success. Whether you’re setting up your shop in a dedicated building, converting a garage, or utilizing a basement space, the right location can enhance productivity and functionality. Here are some factors to consider when choosing the location for your woodworking shop.

Accessibility and Convenience

First and foremost, the location should be easily accessible for both yourself and any clients or customers you may have. Consider proximity to major roads or highways, public transportation, and parking availability. If you anticipate receiving frequent deliveries of materials or large pieces of equipment, ensure the location allows for easy access and maneuverability.

Additionally, convenience is key. If your woodworking shop is located too far from your home, you may find yourself less motivated to spend time there. Choose a location that is convenient for you, taking into account factors such as travel time, availability of supplies and resources, and the overall experience of accessing your shop.

Space and Layout

The size and layout of the space you choose will significantly impact the functionality and organization of your woodworking shop. Consider the overall square footage needed for your shop and ensure there is enough room for your tools, workbenches, and storage solutions.

Take into account the layout of the space and how it can accommodate your workflow. Is there ample room for maneuvering between workstations? Can you easily access and move larger pieces of machinery? Does the space allow for efficient organization and storage? These are all questions to consider when selecting a location for your woodworking shop.

Noise and Disturbance

Woodworking can generate noise and produce dust. If your shop is located in a commercial or residential area, it’s important to consider the impact on neighbors or other tenants. Look for a location that either has adequate soundproofing or is situated in an area where noise disturbances will be minimal.

Similarly, if your shop produces a significant amount of dust or fumes, consider ventilation options to keep the air clean and safe. Some locations may have restrictions or regulations regarding dust collection systems and air quality, so ensure you comply with any necessary regulations when choosing your location.

Optimizing Workflow in Your Woodworking Shop

Creating an efficient and productive woodworking shop goes beyond its size and location. Optimizing your workflow can make a significant difference in the quality of your work, the speed at which you complete projects, and your overall enjoyment of the woodworking process. Here are some strategies to consider when seeking to optimize your woodworking shop workflow.

Designing a Logical Layout

The layout of your woodworking shop should promote a logical flow, minimizing the time wasted in moving between workstations or retrieving tools. Start by identifying the most frequently used tools and placing them within arm’s reach of your main work area. Organize your tools and materials according to the frequency with which you use them, making sure they are easily accessible but not obstructing your workspace.

Consider the sequence of tasks in your woodworking process and arrange your shop accordingly. For example, if you often move from cutting materials to sanding and assembly, ensure that these areas are close together, allowing for efficient movement between them.

Ergonomics and Comfort

It’s important to prioritize ergonomics and comfort in your woodworking shop to prevent fatigue and injury. Position your workbench and tools at an appropriate height that is comfortable for your body and allows for proper posture while working. Invest in ergonomic chairs or padded mats for areas where you may spend extended periods standing or sitting.

Additionally, pay attention to lighting in your shop. Proper lighting is essential for accurate measurements and detailed work. Aim for a combination of natural and artificial lighting to ensure a well-lit workspace.

Implement Organization Systems

A cluttered and disorganized shop not only slows down your workflow but also increases the risk of accidents. Implementing organization systems can help keep your tools, materials, and work areas tidy and efficient. Utilize wall-mounted storage solutions, drawer organizers, and labeled bins to ensure everything has its designated place.

Consider color-coding or labeling systems to easily identify different types of wood or sizes of fasteners. Tidy up your shop at the end of each work session to start fresh the next day, ensuring a clean and efficient workspace.

Utilize Time-Saving Techniques

Woodworking involves a variety of tasks, and finding ways to save time can significantly improve your overall workflow. Invest in time-saving tools and equipment, such as power sanders or router jigs, that can streamline certain processes.

Batch processing is another time-saving technique. Group similar tasks together and complete them in batches. For example, if you need to make several identical cuts, do them all at once rather than individually for each project.

Conclusion

Creating the perfect woodworking shop involves careful consideration of its size, location, and workflow optimization. By taking into account the nature of your projects, the tools and equipment you own, and your workspace needs, you can design a woodworking shop that is functional, efficient, and a joy to work in.

Remember to consider accessibility, convenience, and noise levels when selecting a location. Focus on logical layout design, ergonomic considerations, and implementing organization systems to optimize workflow. With a well-designed and well-utilized woodworking shop, you’ll be on your way to creating beautiful, handcrafted pieces and enjoying the process every step of the way.

Key Takeaways: How Big Does a Woodworking Shop Need to Be?

- A woodworking shop should have enough space to accommodate essential tools and equipment.

- Consider the types and sizes of projects you plan to work on to determine the required shop size.

- Account for workbenches, tool storage, and material storage when calculating space needed.

- Ensure there is enough room for safe and efficient movement around the shop.

- Consider additional space for future expansion and growth of your woodworking projects.

Frequently Asked Questions

Welcome to our woodworking shop FAQ! Below are some common questions about determining the size of a woodworking shop and their answers. Whether you’re a beginner or a seasoned woodworker, finding the right shop size is crucial for productivity and comfort.

What factors should I consider when determining the size of my woodworking shop?

When deciding on the size of your woodworking shop, several factors should be taken into account. Firstly, consider the size of the projects you plan to work on. Larger projects may require more space for maneuvering and storage. Additionally, think about the equipment you’ll be using. Larger machinery may require more space and clearance. Furthermore, take into consideration the number of people working in the shop. If you plan to work alone, a smaller shop may be sufficient. However, if you’ll have multiple people working simultaneously, more space may be needed to ensure comfort and safety.

Lastly, consider your future plans and ambitions. If you anticipate expanding your woodworking business or taking on larger projects in the future, it may be wise to allocate more space from the start. It’s always better to have a bit more space than you currently need, rather than feeling cramped and limited as your woodworking endeavors evolve.

What is the minimum size for a small woodworking shop?

The minimum size for a small woodworking shop can vary depending on the projects you plan to undertake. However, a general guideline is to aim for a minimum of 200-400 square feet of dedicated shop space. This should provide enough room for essential woodworking equipment, a workbench, and storage. However, keep in mind that this size is more suited for hobbyists or those working on small-scale projects.

If you have the space, it’s always better to aim for a slightly larger shop size. This will allow for more flexibility, ease of movement, and improved organization. Additionally, consider the layout and flow of the workshop. Smart organization and an efficient use of space can make even a small shop feel more spacious and functional.

What size shop do I need for a professional woodworking business?

For a professional woodworking business, the size of the shop will depend on various factors. The first consideration is the scale of projects you’ll be working on. If you primarily create smaller items or furniture, a shop in the range of 600-1000 square feet may be sufficient. This size allows for proper storage, machinery, and workstations.

However, if you plan on engaging in larger-scale projects or have a team of woodworkers working together, a shop size ranging from 1000-2000 square feet or more may be necessary. This will provide ample space for necessary equipment, multiple workstations, and comfortable movement within the shop. Keep in mind that as your business grows, you may need to expand your shop further to accommodate increased demand and larger projects.

How can I make the most out of a small woodworking shop?

Even with a small woodworking shop, there are several strategies to optimize your space and make the most out of it. First, prioritize efficient storage solutions such as wall-mounted shelving, overhead storage racks, and storage bins. Utilize vertical space to maximize storage options while keeping the floor area clear.

Secondly, invest in versatile and compact woodworking tools that can perform multiple functions. This will reduce the need for large, specialized machinery, thus saving space. Additionally, consider mobile workstations or workbenches that can be easily moved or folded when not in use.

Can I convert an existing space into a woodworking shop?

Absolutely! Converting an existing space, such as a garage, basement, or spare room, can be a great option for a woodworking shop. Before making any modifications, ensure that the space has the necessary requirements such as sufficient lighting, electrical outlets, and ventilation.

Consider the dimensions of the space and ensure it provides enough room for your woodworking activities. Evaluate the layout and plan for efficient storage and workstation placement. With proper planning and organization, you can successfully transform an existing space into a functional woodworking shop that suits your needs.

Summary

Your woodworking shop doesn’t have to be huge, but it should be organized and functional.

You should consider the space you have available, the types of woodworking projects you plan to undertake, and the tools and equipment you need. A good starting point is around 400 square feet, but you can make do with less if you prioritize efficiency and organization. Remember, it’s not just about the size, but also about making the most of the space you have.