If you’ve ever wondered how dangerous a lathe can be, you’re in the right place! Let’s dive into the world of lathes and find out just how risky they can be.

First things first, what exactly is a lathe? Well, it’s a machine used to shape wood, metal, or other materials by rotating them against a cutting tool. Sounds pretty cool, right? But with great power comes great responsibility, and lathes aren’t without their hazards.

So, in this article, we’ll explore the potential risks associated with lathes and provide some tips to stay safe while using them. Let’s get started and learn all about the dangers of lathes!

When it comes to working with a lathe, it’s important to be aware of the potential dangers involved. While lathes can be incredibly useful tools, they can also be hazardous if not used properly. Understanding and following safety guidelines is crucial to prevent accidents. Always wear appropriate protective gear, properly secure workpieces, and familiarize yourself with the lathe’s features and controls. Additionally, receive proper training and supervision to ensure safe operation. Remember, with proper precautions, the risks associated with using a lathe can be minimized.

How Dangerous is a Lathe?

A lathe is a powerful and versatile machine used in woodworking and metalworking. With its spinning blades and fast-moving parts, one might wonder just how dangerous this equipment can be. In this article, we will explore the potential hazards associated with using a lathe and provide valuable information to ensure safe operation. From safety precautions to common accidents and preventive measures, we will delve into the risks involved and how to mitigate them. So let’s dive in and understand just how dangerous a lathe can be.

Important Safety Measures to Consider

Before we explore the potential dangers of working with a lathe, it is crucial to emphasize the importance of following safety measures. By adhering to these guidelines, you can significantly minimize the risks involved and create a safer working environment for yourself and others around you.

Proper Training and Experience

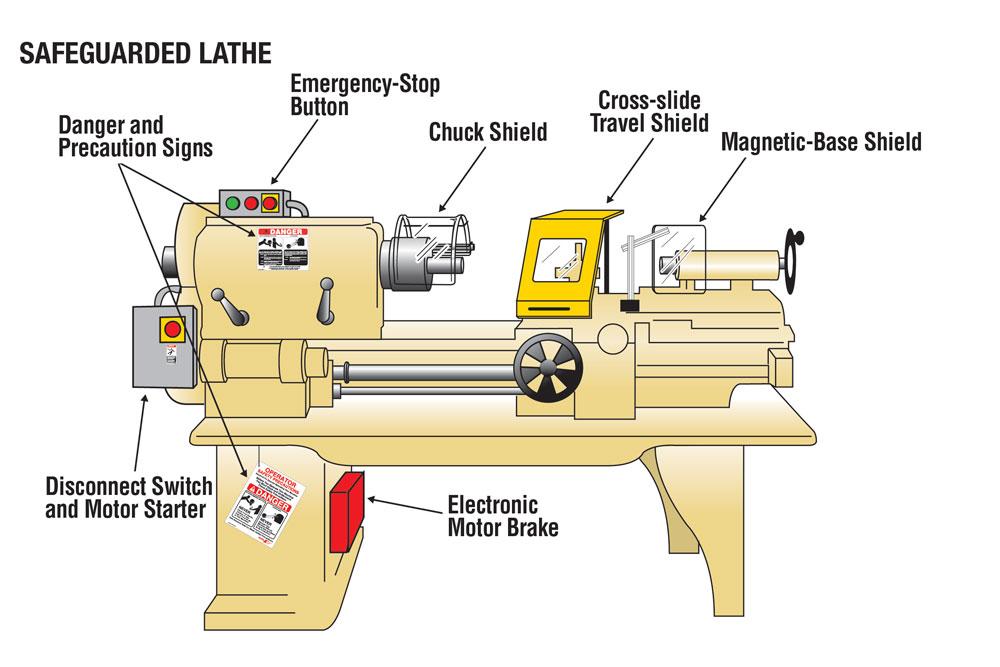

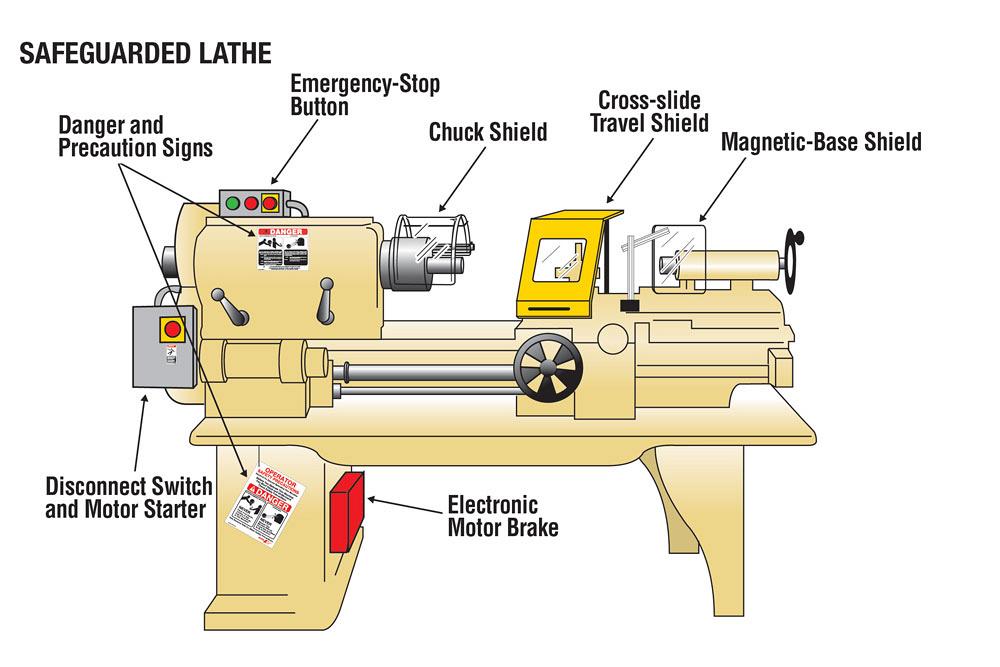

The first step in ensuring safety is to have adequate training and experience in operating a lathe. Proper instruction on how to use the machine, understanding its components and potential risks, and practicing under the supervision of an experienced professional are essential. Familiarize yourself with the operating manual, safety guidelines, and any specific requirements for the lathe model you are using.

It is also crucial to regularly refresh your knowledge and skills through continued education and training programs. Staying up to date with best practices and advancements in lathe safety will help you maintain a safe and efficient workspace.

Remember, knowledge and experience are your greatest tools for safety when working with a lathe.

Protective Gear and Clothing

Wearing proper protective gear is vital to minimize the risks of working with a lathe. Always wear safety glasses or a face shield to protect your eyes from flying debris and sparks. Additionally, consider wearing ear protection to reduce the noise levels associated with the machine.

In terms of clothing, avoid loose-fitting garments, as they can easily get caught in the lathe’s moving parts. Choose fitted clothing made of durable materials that can withstand potential snags. It is also recommended to wear non-slip footwear to maintain stability while operating the machine.

By investing in the right protective gear and clothing, you can significantly reduce the chances of sustaining injuries while working with a lathe.

Common Accidents and Prevention

Despite the potential dangers, accidents involving lathes can be prevented by being aware of common risks and taking the necessary precautions. Here are a few of the most frequently encountered accidents and ways to prevent them:

Entanglement and Clothing-Related Injuries

A common accident involving lathes is when loose-fitting clothing, jewelry, or long hair gets entangled in the moving components of the machine. This can result in severe injuries or even dismemberment.

To prevent entanglement accidents, always ensure that your clothing is well-fitted and tucked away. Avoid wearing accessories or jewelry that can get caught in the lathe. Tie back long hair or wear a cap to prevent it from getting entangled. Regularly inspect the lathe for any loose or protruding parts that could potentially snag your clothing.

Remember, it is crucial to prioritize safety over fashion when working with a lathe.

Projectile Hazards

The high speeds at which lathes operate can cause materials to become projectiles if not secured properly. Improperly secured workpieces or tools can fly off the lathe, posing a significant risk to the operator and those nearby.

To prevent projectile accidents, always securely fasten workpieces to the lathe using appropriate clamps or chucks. Double-check that the workpiece is centered and balanced before starting the machine. Avoid placing hands or tools too close to the workpiece while it is spinning to minimize the risk of being hit if it dislodges.

By taking these precautions, you can prevent potential accidents caused by flying projectiles.

Importance of Regular Maintenance and Inspections

In addition to following safety measures and preventing accidents, it is essential to prioritize regular maintenance and inspections for your lathe. Proper maintenance ensures that all components are in good working order, reducing the risk of malfunctions and accidents.

Scheduled Lubrication and Cleaning

Regularly lubricating your lathe’s moving parts according to the manufacturer’s guidelines can help prevent overheating and unnecessary wear and tear. Clean the machine after each use to remove any debris or buildup that could affect its performance.

Inspection of Key Components

Inspect the lathe’s key components, such as the belts, bearings, and blades, on a regular basis. Look for signs of wear, damage, or misalignment. Replace any worn-out or damaged parts promptly to ensure safe operation.

Electrical Safety

If your lathe is powered by electricity, inspect the cords and plugs for any fraying or damage. Ensure that the power supply is grounded correctly to minimize the risk of electrical shocks.

Regular maintenance and inspections play a crucial role in preventing accidents and maintaining the overall safety of your lathe.

Key Takeaways: How Dangerous is a Lathe?

- A lathe can be dangerous if not used properly.

- Accidents can occur due to lack of experience or improper training.

- Wearing appropriate safety equipment is crucial when working with a lathe.

- Being aware of potential hazards and taking precautions is necessary for safe lathe operation.

- Regular maintenance and inspections help prevent accidents and ensure the lathe is in good working condition.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section regarding the dangers of using a lathe. Below, you’ll find answers to common queries about the potential risks associated with operating this powerful tool.

1. What safety precautions should I take when using a lathe?

When using a lathe, it is crucial to prioritize safety to avoid accidents. Firstly, always wear appropriate personal protective equipment, such as safety glasses, gloves, and closed-toe shoes. Ensure the lathe is properly grounded and the work area is well-lit to prevent trips and falls. It is also important to keep loose clothing and long hair secured away from moving parts. Additionally, make sure to read and follow the manufacturer’s guidelines and receive proper training before using a lathe.

Furthermore, practice good housekeeping by removing any obstructions or debris that could interfere with the lathe’s operation. Never leave the machine unattended while it is still running, and always keep a well-maintained fire extinguisher nearby. By following these safety precautions, you can significantly reduce the potential dangers associated with using a lathe.

2. What are some common accidents that can occur when operating a lathe?

While using a lathe, accidents can happen if proper safety measures are not observed. Some common accidents include getting entangled in rotating parts or tools, being struck by flying debris, or suffering from cuts and lacerations when using sharp cutting tools. Additionally, injury can occur due to kickback, which is when the workpiece gets caught and forcefully thrown back towards the operator. It is essential to be aware of these potential accidents and take the necessary precautions to prevent them.

Moreover, lack of experience, improper training, or failing to follow safety guidelines can increase the risk of accidents. Remember, a lathe is a powerful machine that should be approached with caution and respect. By understanding and actively avoiding common accidents, you can help ensure a safe working environment when using a lathe.

3. Are there any health risks associated with using a lathe?

Yes, there are potential health risks associated with using a lathe, particularly when it comes to exposure to harmful substances. For example, the process of turning wood or other materials can produce fine dust particles that, when inhaled, can lead to respiratory issues. To mitigate this risk, ensure proper ventilation in the workspace and wear a dust mask or respirator to prevent inhalation of these particles.

Additionally, if the lathe involves working with metals, there may be a risk of exposure to metal shavings or coolant fluids, which could lead to skin irritation or allergic reactions. It is advisable to wear appropriate protective clothing, such as long sleeves and gloves, to minimize contact with these substances. By being aware of the potential health risks and taking necessary precautions, you can reduce the impact on your well-being when using a lathe.

4. Can a lathe cause electrical hazards?

Yes, a lathe can present electrical hazards if not used correctly. Improper grounding of the lathe or using faulty electrical connections can increase the risk of electrical shocks. It is crucial to ensure that the lathe is properly grounded and that all electrical connections are secure and in good condition. Regularly inspect power cords for any signs of wear or damage and replace them if necessary.

Furthermore, always use the correct voltage and amperage for the lathe, as exceeding its electrical capacities can lead to overheating and electrical malfunctions. It is important to have a qualified electrician perform any necessary electrical work or repairs on the lathe to maintain safety. By adhering to proper electrical guidelines, you can minimize the electrical hazards associated with using a lathe.

5. How can I maintain a safe work environment when using a lathe?

Maintaining a safe work environment is crucial when operating a lathe. Start by keeping the work area clean and organized, free from clutter and potential tripping hazards. Ensure that the lathe itself is regularly inspected and well-maintained to prevent any mechanical failures that could lead to accidents.

Implement a comprehensive training program for all lathe users to ensure that everyone is aware of the proper operating procedures and safety precautions. Regularly review and reinforce these guidelines to keep safety at the forefront. Additionally, establish an emergency plan and make sure all users are familiar with it, including the location of emergency stops, fire extinguishers, and the procedure for reporting accidents or injuries.

By creating a culture of safety, providing adequate training, and maintaining a clean and organized workspace, you can significantly minimize the risks and maintain a safe working environment when using a lathe.

Summary

Okay, let’s wrap this up! So we’ve been talking about lathes and how dangerous they can be. But don’t worry, you can still use them safely with some precautions. Remember to wear safety glasses, keep loose clothes and hair out of the way, and use proper tools. It’s also important to follow the instructions and ask for help if you’re not sure. Lathes can be fun and useful, you just need to be careful and take the right steps to stay safe. Keep creating and stay safe, my friend!