When it comes to woodworking, there’s a lot to learn and explore. One important tool in the woodworker’s arsenal is the wood lathe. But have you ever wondered just how important the reverse feature is on a wood lathe? Well, you’ve come to the right place! In this article, we’re going to dive into the world of wood lathes and uncover why the reverse function is a game-changer for woodturners.

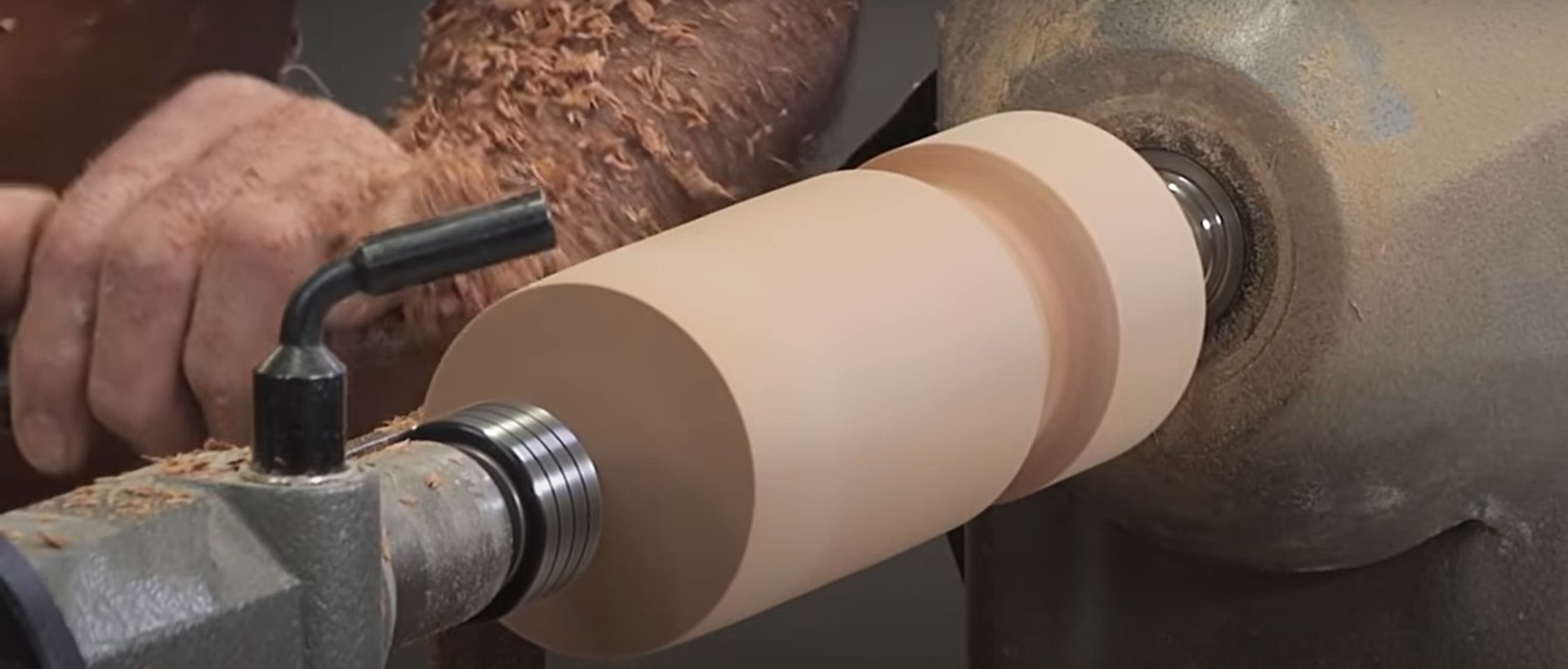

Imagine this: you’re working on a woodworking project, shaping a piece of wood on your lathe. Suddenly, you encounter a knot or a difficult grain pattern. What do you do? This is where the reverse feature on a wood lathe becomes your best friend. With the ability to spin the piece of wood in the opposite direction, you gain more control and flexibility to tackle those challenging areas with ease.

But that’s not all! The reverse function on a wood lathe also opens up a whole new world of possibilities for creativity. You can create intricate designs, add textures, or even carve spirals into your wooden creations. The reverse feature allows you to explore unique techniques and take your turning skills to the next level. So, whether you’re a beginner or a seasoned woodturner, understanding the importance of the reverse function on a wood lathe is crucial for expanding your woodworking horizons.

When it comes to a wood lathe, having a reverse feature can be incredibly important. It allows you to reverse the rotation of the lathe, which is useful for various woodworking tasks. With reverse, you can smooth out rough spots, create decorative patterns, and even sand the wood more efficiently. The ability to switch between forward and reverse adds versatility to your woodworking projects and makes the lathe a more valuable tool in your workshop.

How Important is Reverse on a Wood Lathe?

A wood lathe is a versatile tool used by woodworkers to shape and turn wood pieces into various objects such as bowls, vases, and table legs. One feature that is often debated among woodworkers is the inclusion of a reverse function on a wood lathe. The reverse function allows the woodworker to change the direction of rotation of the lathe’s spindle. In this article, we will discuss the importance of the reverse feature on a wood lathe and its impact on woodworking projects.

1. Versatility and Flexibility

The reverse function on a wood lathe adds versatility and flexibility to woodworking projects. It allows woodworkers to work on both the front and back sides of their projects without having to reposition the piece manually. This is especially useful when creating intricate designs or when working with delicate pieces that require multiple passes or finishing touches on both sides.

With the reverse function, woodturners can easily switch between forward and reverse rotation, enabling them to make adjustments, add decorative details, or correct any imperfections on the surface. This feature significantly reduces the time and effort required to produce high-quality and symmetrical pieces.

Additionally, the reverse function enables woodturners to experiment with new techniques, such as reverse turning, where the piece is turned from the opposite direction. This technique allows for unique designs and textures that are not achievable with traditional forward turning alone.

2. Safety and Control

Another important aspect of having a reverse function on a wood lathe is safety. When working on certain projects, such as hollow vessels or hollowing out the interior of bowls, the reverse function helps to safely remove the wood chips or shavings from the piece. By running the lathe in reverse, the wood chips move away from the tool, reducing the risk of accidents and improving overall visibility.

The reverse function also provides better control and stability when working with difficult or challenging materials. For example, when turning wet or green wood, which tends to be more prone to tear-out or cracking, the reverse function allows the woodworker to work with the grain, minimizing these issues and achieving a smoother finish.

Furthermore, the reverse function can be used to eliminate or minimize the appearance of tear-out or grain irregularities. By reversing the rotation direction and making light passes against the grain, the wood fibers can be sheared off cleanly, resulting in a cleaner surface and reducing the need for additional sanding and refinishing.

3. Time and Efficiency

Woodworkers often value the reverse function on a wood lathe for its ability to save time and increase overall efficiency. Instead of stopping the lathe, removing the piece, and manually flipping it to work on the opposite side, the woodturner can simply utilize the reverse function and continue working without interruption.

This time-saving feature is particularly beneficial when working on larger and heavier pieces that may require frequent adjustments or when creating multiple identical objects. By eliminating the need for constant repositioning, the woodworker can maintain a steady workflow and complete projects more efficiently.

Moreover, the reverse function allows woodworkers to effortlessly sand and finish both sides of a piece without having to handle it manually. This not only reduces the risk of damaging the workpiece but also ensures a consistent finish and enhances the overall quality of the final product.

Additional Considerations

While the reverse function on a wood lathe offers numerous advantages, it may not be essential or necessary for every woodworker or project. The importance of the reverse feature largely depends on the type of woodworking projects you undertake and your personal preferences.

4. Choosing the Right Wood Lathe

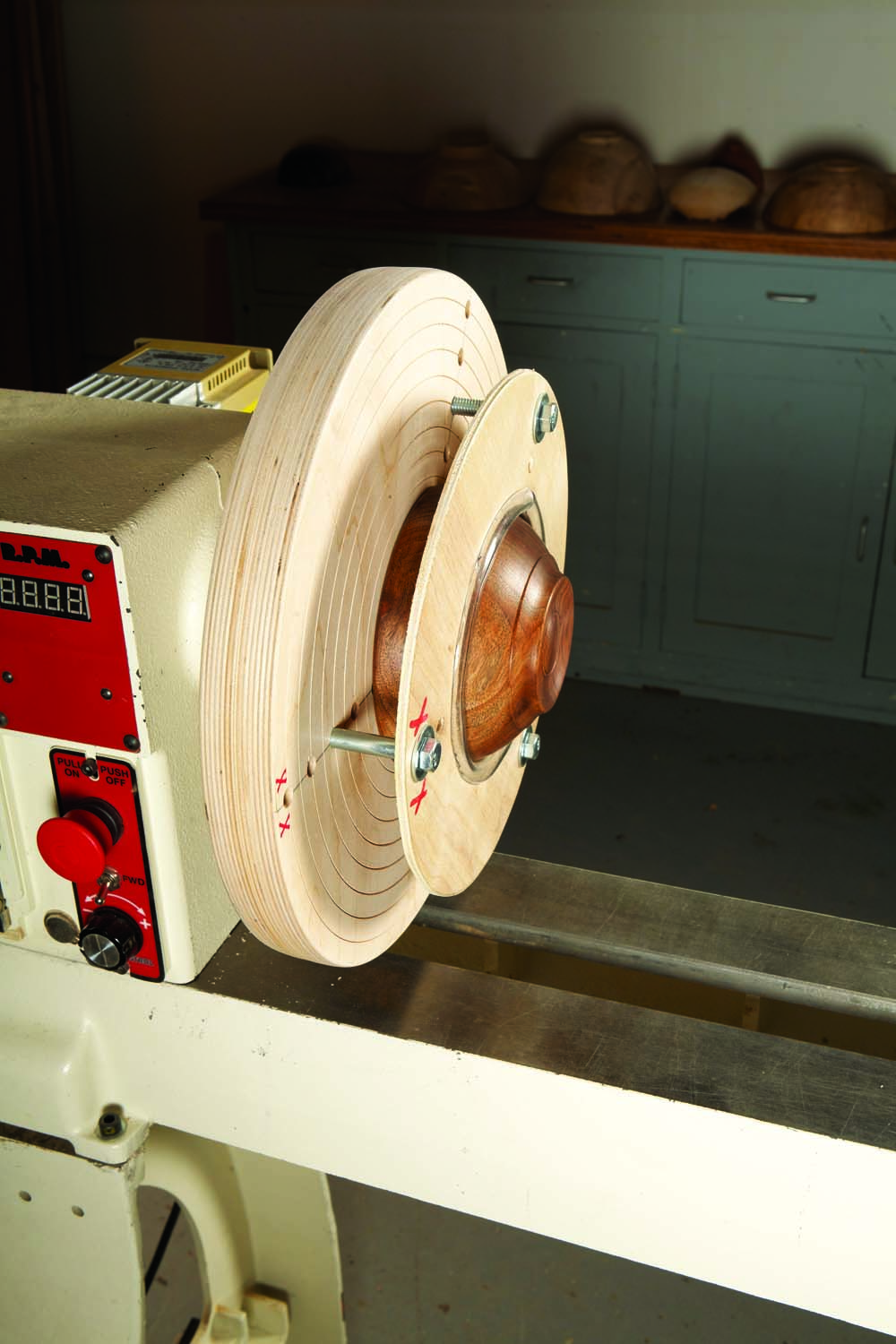

When purchasing a wood lathe, it’s essential to consider your specific needs and the type of projects you intend to tackle. Some wood lathes come with built-in reverse functionality, while others may require an additional accessory or upgrade to enable the reverse feature.

If you primarily work on smaller projects or rarely require the use of a reverse function, opting for a wood lathe without this feature may be more cost-effective. However, if you frequently work on larger, more complex pieces or value the convenience and flexibility of the reverse function, investing in a wood lathe with built-in reverse capabilities is highly recommended.

5. Developing Skills and Techniques

Regardless of whether your wood lathe has a reverse function or not, it’s crucial to focus on developing your skills and techniques as a woodturner. Mastering the fundamentals of woodturning, such as tool control, sharpening, and understanding grain direction, will greatly contribute to the success and quality of your projects.

Take the time to experiment with different tools, materials, and finishes to discover what works best for you. Consider joining a woodworking community or taking classes to learn from experienced woodturners and gain valuable insights and tips.

6. Practice Proper Safety Measures

Lastly, regardless of whether you have a wood lathe with reverse capabilities or not, it is essential to prioritize safety at all times. Always wear appropriate protective gear, such as safety glasses, a face shield, and hearing protection. Familiarize yourself with the safety features and guidelines provided by the manufacturer.

Additionally, make sure your workspace is clean and well-lit, and keep your tools clean and sharp to ensure optimal performance and minimize the risk of accidents.

Conclusion

The reverse function can be a valuable addition to a wood lathe, offering versatility, safety, and time-saving benefits for woodworkers. It allows for greater flexibility in working on both sides of a project, enhances control and stability, and improves overall efficiency. However, its importance may vary depending on the individual woodworker’s needs and the nature of the projects undertaken.

Regardless of whether a wood lathe has a reverse function or not, focusing on developing woodworking skills, choosing the right lathe for specific requirements, and prioritizing safety measures are essential for successful and enjoyable woodturning experiences.

Key Takeaways: How Important is Reverse on a Wood Lathe?

- Using reverse on a wood lathe can help prevent tear-out and splintering of the wood.

- It allows for easier removal of wood chips and shavings from the workpiece.

- Reverse functionality enables the creation of unique spiral patterns and fluting designs.

- It facilitates the sanding and finishing process by allowing access to hard-to-reach areas.

- Reverse can be particularly useful for certain turning techniques like hollowing out bowls and vases.

Frequently Asked Questions

Are you curious about the importance of having a reverse feature on a wood lathe? Here are some common questions and answers to help you understand its significance.

1. How does the reverse feature on a wood lathe benefit me?

The reverse feature on a wood lathe adds versatility to your woodworking projects. It allows you to change the direction of rotation, which can be beneficial in several ways. For example, when turning delicate pieces of wood, the reverse feature allows for easier sanding and finishing. It also helps eliminate tear-out, creating a smoother and more polished final product. Additionally, when working on irregularly shaped or asymmetrical pieces, reversing the rotation can help you get a different perspective and make it easier to access certain areas.

Moreover, the reverse feature can assist in fixing mistakes. If you make an error while turning, you can simply reverse the rotation and undo the damage. This can save you time, material, and frustration. Overall, the reverse feature is a valuable tool that enhances your woodworking capabilities and offers more creative possibilities.

2. Can I still use a wood lathe without a reverse feature?

Yes, you can definitely use a wood lathe without a reverse feature. Many woodworkers have been using lathes without this option for years and have created outstanding pieces of art. The reverse feature is not a necessity, but rather an added convenience that can enhance your woodworking experience. Without it, you need to be more meticulous and plan your projects accordingly. To minimize tear-out, sanding and finishing may require a bit more effort and patience. However, with skill and practice, you can achieve excellent results on a lathe without the reverse feature.

If you’re just starting out or working on simpler projects, a wood lathe without a reverse feature can be a great option. It’s essential to focus on developing your turning skills and techniques, as those are the foundation of creating quality woodwork. As you gain more experience and work on more complex projects, you can consider upgrading to a lathe with a reverse feature to expand your possibilities.

3. Are there any safety considerations when using the reverse feature on a wood lathe?

Using the reverse feature on a wood lathe does come with a few safety considerations. When operating in reverse, it’s important to be aware of the potential for the wood piece to become dislodged or fly off the lathe. Make sure that your workpiece is securely attached to the lathe and properly centered to minimize any risks. Always wear appropriate personal protective equipment, such as safety glasses and a face shield, to protect yourself from any unexpected flying debris. Additionally, stay focused and maintain a firm grip on the tool at all times to maintain control and prevent accidents.

It’s also worth noting that using the reverse feature may affect the performance and vibration of your lathe. Before using the reverse function, ensure that your lathe is in good working condition and properly maintained. Any excessive vibration or strange noises should be investigated and resolved before utilizing the reverse feature. By following these safety precautions and regularly maintaining your lathe, you can enjoy the benefits of the reverse feature while ensuring a safe woodworking environment.

4. Can I add a reverse feature to my existing wood lathe?

Whether you can add a reverse feature to your existing wood lathe depends on the specific model and its compatibility with retrofitting options. Some wood lathes may have the option to install a reverse kit or upgrade your motor to include a reverse function. However, not all lathes offer this possibility, so it’s essential to consult the manufacturer’s instructions or reach out to their customer support for guidance.

If your wood lathe doesn’t offer a reverse option or retrofitting solution, you may need to consider upgrading to a lathe that includes the feature. While it can be an investment, upgrading to a lathe with a built-in reverse feature opens up new possibilities for your woodworking projects. It’s a decision that depends on your specific needs, budget, and long-term woodworking goals.

5. What are some tips for effectively using the reverse feature on a wood lathe?

To make the most of the reverse feature on your wood lathe, here are some essential tips:

First, familiarize yourself with the controls and operation of the reverse function. Take the time to read the user manual or watch instructional videos specific to your lathe model. Next, always start with a slow speed when engaging the reverse feature, especially if you’re working on a larger or heavier piece. This allows for smoother transitions and reduces the risk of sudden movements that could compromise safety.

Additionally, take breaks and assess your progress when using the reverse function. It’s a valuable tool, but it’s also important to check your work frequently to ensure your desired outcome is being achieved. Lastly, practice patience and take your time when working in reverse. Familiarize yourself with the different results that can be achieved and experiment with various techniques to further enhance your woodturning skills.

Summary

Having a reverse function on a wood lathe can be helpful for certain woodworking tasks. It allows you to work on both the front and backside of a piece without needing to manually flip it. This is especially useful when making intricate designs or when sanding and finishing a project. However, not all wood lathes have a reverse function, and it is not absolutely necessary for every project. It ultimately depends on the specific needs and preferences of the woodworker.