Hey there! Have you ever wondered how much a CNC lathe weighs? Well, you’re in the right place because we’re about to dive into that question.🕵️♀️

When it comes to CNC lathes, weight plays a crucial role in their functionality and transportation. You might be surprised to learn just how heavy these machines can be! 💪

So, buckle up and get ready to explore the fascinating world of CNC lathes and discover the answer to the burning question, “How much does a CNC lathe weigh?” Let’s dive right in! 🚀

How Much Does a CNC Lathe Weigh?

Welcome to our guide on the weight of CNC lathes. If you’re in the market for a CNC lathe or simply curious about their weight, you’ve come to the right place. In this article, we’ll delve into the various factors that dictate the weight of CNC lathes, the average weight range you can expect, and some additional considerations you should keep in mind. So, let’s get started and explore the fascinating world of CNC lathes and their weight.

Factors Affecting the Weight of CNC Lathes

Before we dive into the specific weight ranges, it’s essential to understand the factors that influence the weight of CNC lathes. The weight of a CNC lathe primarily depends on the following factors:

Type and Size of the CNC Lathe

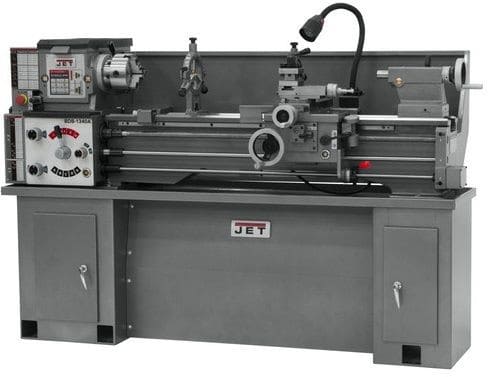

The type and size of the CNC lathe play a crucial role in determining its weight. Larger and more robust lathes with higher horsepower, swing, and bed length will generally weigh more than smaller machines. Additionally, the design and construction of the lathe, including the material used for the bed and components, can affect its weight. Cast iron beds, for example, tend to be heavier than other materials.

Multiple configurations of CNC lathes are available on the market, such as horizontal lathes, vertical lathes, and Swiss-style lathes. Each configuration has its own weight range, with horizontal lathes typically being heavier due to their larger footprint and additional structural components.

Additional Accessories and Attachments

Another factor that contributes to the weight of a CNC lathe is the presence of additional accessories and attachments. These can include things like tool changers, steady rests, tailstocks, and coolant systems. The weight of these attachments will vary depending on the design, material, and size of the lathe. Keep in mind that if you’re purchasing a CNC lathe with specific accessories, their combined weight should be factored into your calculations.

Construction Quality and Materials

The construction quality and materials used in the CNC lathe also impact its weight. Machines built with heavy-duty components and high-quality materials tend to be heavier due to their durability and ability to handle various machining tasks. While a heavier machine may be more challenging to transport, it generally indicates a robust construction that can withstand heavy workloads and provide more accurate machining results.

Weight Range of CNC Lathes

The weight of CNC lathes can vary significantly depending on the aforementioned factors. On average, CNC lathes can weigh anywhere from a few thousand pounds to several tons. Here’s a breakdown of the weight ranges you can typically expect for different sizes and types of CNC lathes:

Small CNC Lathes:

Small CNC lathes, also known as benchtop lathes, are lightweight and designed for smaller-scale projects or hobbyist use. They generally weigh between 500 pounds to 2,000 pounds (227 kilograms to 907 kilograms). These lathes offer portability and are suitable for limited space or individuals who don’t require heavy-duty machining capabilities.

Medium-Sized CNC Lathes:

Medium-sized CNC lathes are more substantial and can handle a wider range of machining tasks. They typically weigh between 2,000 pounds to 10,000 pounds (907 kilograms to 4,536 kilograms). These lathes strike a balance between size, weight, and machining capabilities, making them ideal for small to medium-sized businesses and workshops.

Large CNC Lathes:

Large CNC lathes are heavy-duty machines used for industrial applications and heavy machining tasks. These machines can weigh anywhere from 10,000 pounds to 200,000 pounds (4,536 kilograms to 90,718 kilograms) or even more, depending on their size and configuration. Large CNC lathes often require professional installation and dedicated infrastructure due to their weight and size.

It’s important to note that these weight ranges are approximate and can vary from one manufacturer to another. When considering a CNC lathe for your specific needs, always refer to the manufacturer’s specifications for accurate weight information.

Additional Considerations When Dealing with CNC Lathe Weight

Transportation and Installation

Due to their size and weight, moving and installing CNC lathes can be a complex process. It’s crucial to plan for the transportation and installation logistics well in advance. This may involve hiring professional riggers, using specialized equipment, and ensuring the proper tools are available to handle the machine safely. Additionally, ensure that the location where the CNC lathe will be installed can support its weight and has adequate floor space.

Floor Load Capacity

Since CNC lathes are hefty machines, it’s essential to consider the floor load capacity of the area where you plan to install the lathe. The floor must be able to withstand the weight of the machine and any additional equipment that may be attached to it. Consult with a structural engineer or an expert to determine the load-bearing capacity of your floor and make any necessary modifications to ensure a safe and stable installation.

Weight Distribution

When dealing with the weight of a CNC lathe, it’s not only the total weight that matters. The distribution of weight across the lathe also plays a role in stability and performance. Understanding the weight distribution can help you determine if any additional supports or reinforcement are required during installation.

Conclusion

In conclusion, the weight of a CNC lathe can vary depending on factors such as its type, size, construction quality, and accessories. Small CNC lathes typically weigh between 500 to 2,000 pounds, while medium-sized lathes range from 2,000 to 10,000 pounds. Large CNC lathes can weigh anywhere from 10,000 to 200,000 pounds or more. When dealing with CNC lathe weight, it’s important to consider transportation and installation logistics, floor load capacity, and weight distribution. By understanding these factors, you can ensure a safe and successful installation of your CNC lathe.

Key Takeaways: How Much Does a CNC Lathe Weigh?

- A CNC lathe can weigh anywhere between a few hundred pounds to several tons.

- Large industrial CNC lathes can weigh up to 50,000 pounds or more.

- Heavy-duty CNC lathes used in manufacturing factories are typically heavier than smaller hobbyist models.

- The weight of a CNC lathe is influenced by its size, construction, and the materials it is made of.

- Before purchasing a CNC lathe, make sure to consider its weight and ensure that your workspace can accommodate it.

Frequently Asked Questions

In the world of machining, CNC lathes are a common tool. While these machines are known for their precision and efficiency, many people wonder about their weight. Here are some frequently asked questions about the weight of CNC lathes:

1. How heavy is a typical CNC lathe?

A typical CNC lathe can weigh anywhere between 2,000 to 20,000 pounds. The weight of a CNC lathe depends on various factors, such as its size, design, and functionality. Smaller lathes used for light-duty applications tend to be on the lighter end of the spectrum, while larger, heavy-duty lathes can be significantly heavier. It’s important to consider the weight of a CNC lathe when planning for installation, maintenance, and transportation.

Moreover, the weight of the CNC lathe also depends on the specific configuration, as additional features like tool changers, coolant systems, and live tooling can add to its overall weight. When selecting a CNC lathe, it’s crucial to consider the weight capacity of your facility or the transportation method you plan to use.

2. What factors contribute to the weight of a CNC lathe?

Several factors contribute to the weight of a CNC lathe. One significant factor is the size and construction of the machine. Bigger lathes tend to be heavier due to the additional materials and components required to support their larger structure. Additionally, the material used in the construction of the lathe, such as cast iron or steel, can significantly impact its weight.

The complexity and functionality of a CNC lathe also play a role in its weight. Lathes with advanced features like multiple axes, automatic tool changers, and high-speed spindle motors may be heavier compared to simpler models. Furthermore, the presence of accessories like chip conveyors, coolant systems, and enclosures can contribute to the overall weight of the machine. Therefore, it’s essential to consider these factors when determining the weight of a CNC lathe.

3. How does the weight of a CNC lathe affect its stability?

The weight of a CNC lathe is directly related to its stability while machining. Heavier lathes tend to be more stable, as they can absorb vibrations and remain rigid during cutting operations. This stability is crucial for maintaining precision, reducing chatter, and improving the overall surface finish of machined parts.

Furthermore, the weight of the lathe helps dampen vibrations caused by the cutting forces, thereby reducing strain on the machine components and prolonging the tool’s life. Lighter lathes, on the other hand, may be more prone to vibrations and flexing, which can result in lower machining quality and decreased tool life. Therefore, a sturdy and well-weighted CNC lathe is essential for achieving optimal machining performance.

4. Are there any safety considerations when dealing with heavy CNC lathes?

Yes, safety is a crucial consideration when dealing with heavy CNC lathes. These machines are often large and have moving parts, which can pose potential risks. When installing or moving a CNC lathe, it’s essential to have a proper lifting mechanism, such as cranes or forklifts, and trained personnel to ensure safe handling.

Additionally, proper grounding, secure anchoring, and a stable foundation are important for the safe operation of a heavy CNC lathe. Regular maintenance and inspection of the machine’s structural integrity and components are also necessary to prevent any accidents or malfunctions. Following manufacturer guidelines, safety protocols, and using personal protective equipment when necessary are vital to ensure the well-being of operators and the longevity of the CNC lathe.

5. Can the weight of a CNC lathe affect energy consumption?

Yes, the weight of a CNC lathe can have an impact on energy consumption. Heavier machines tend to require more power to move and accelerate their components, resulting in higher energy consumption. However, it’s important to note that the weight is just one factor among many that contribute to energy usage.

The efficiency of the machine design, the type and condition of the motors, the utilization of power-saving features, and the overall operational practices also play significant roles in determining energy consumption. Therefore, while the weight of a CNC lathe can influence energy usage to some extent, it should be considered alongside other factors for a comprehensive assessment of energy efficiency.

Summary

Sometimes, CNC lathes weigh a lot because they are made with heavy materials like steel. The weight can vary depending on the size and type of lathe.

However, smaller CNC lathes typically weigh around 1,500 to 2,000 pounds, while larger industrial ones can weigh up to 40,000 pounds! So, they can be pretty heavy machines.

Remember, the weight of a CNC lathe is an important consideration when transporting or installing one. Make sure to consult the manufacturer’s specifications for accurate weight information.