Looking to find out how much a lathe machine weighs? Well, you’ve come to the right place! Whether you’re a woodworking enthusiast or just curious about these powerful machines, we’ve got you covered. In this article, we’ll dive into the world of lathe machines, exploring their weight and why it matters. So, let’s get started and unravel the mysteries of lathe machine weights!

When it comes to the weight of a lathe machine, there’s no simple answer. You see, lathe machines come in different sizes and configurations, which means their weight can vary significantly. From compact tabletop models to heavy-duty industrial lathes, there’s a wide range to choose from. Join us as we explore the factors that contribute to a lathe machine’s weight, shedding light on this fascinating topic.

So, why does the weight of a lathe machine matter? Well, it’s not just about the numbers on the scale. The weight of a lathe machine is an important consideration for a few reasons. Firstly, it affects the stability and durability of the machine. A heavier lathe can withstand more vibrations and provide a sturdier platform for precision work. Additionally, the weight can determine the ease of transportation and installation, especially if you’re planning to move or relocate the machine. Understanding the weight of a lathe machine is crucial when it comes to making informed decisions and ensuring a smooth woodworking experience. Are you ready to delve deeper into this fascinating topic? Let’s explore together!

How Much Does a Lathe Machine Weigh? Exploring the Weight of Lathe Machines

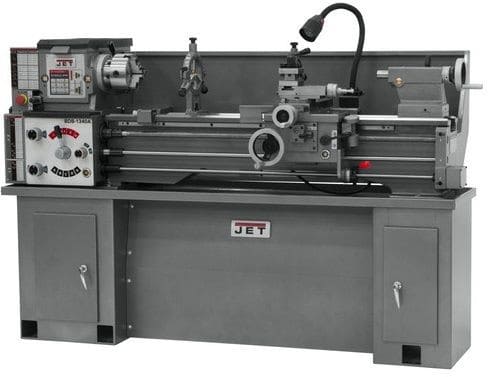

Lathe machines are essential tools in the world of machining, used for shaping and cutting various materials such as wood, metal, and plastic. These machines are known for their precision and versatility. However, one question that often arises is how much does a lathe machine weigh? In this article, we will delve into the factors that contribute to the weight of lathe machines and explore the different types and sizes of lathes available in the market. So, let’s get started!

The Factors Affecting the Weight of Lathe Machines

1. Size and Type of Lathe Machine

The first factor that determines the weight of a lathe machine is its size and type. Lathe machines come in various sizes, ranging from small benchtop lathes to large industrial lathes. The bigger the size and the heavier the construction of the machine, the more it will weigh.

Additionally, the type of lathe machine also plays a role. For example, a manual lathe machine will generally weigh less than a computer numerical control (CNC) lathe machine due to the additional components and electronic systems present in CNC machines.

2. Construction Materials

Another significant factor influencing the weight of a lathe machine is the construction materials used. Generally, lathe machines are constructed using heavy-duty cast iron or steel. These materials provide the necessary stability, rigidity, and vibration damping required for accurate machining. However, they also contribute to the overall weight of the machine.

The choice of construction materials depends on the intended use and durability requirements of the lathe machine. While cast iron is commonly used for most lathe machines, larger industrial models may incorporate steel components for added strength.

3. Accessories and Additional Components

The inclusion of accessories and additional components can significantly impact the weight of a lathe machine. These may include features such as motor assemblies, tool rests, tailstocks, chucks, and steady rests.

Moreover, certain lathe machines may have additional features like milling attachments, thread-cutting capabilities, or multiple tool turrets. Each of these additions will contribute to the overall weight of the machine. It’s important to consider the specific requirements and functionalities you need before choosing a lathe machine, as these extras can add weight and affect portability.

Types and Weight Ranges of Lathe Machines

1. Benchtop Lathe Machines

Benchtop lathe machines are small and compact, designed to be placed on a workbench or tabletop. These machines are ideal for hobbyists, DIY enthusiasts, and those with limited space. Benchtop lathes typically weigh between 100 to 400 pounds (45 to 181 kilograms) depending on their size and construction materials.

2. Engine Lathes

Engine lathes, also known as center lathes, are versatile machines used for a wide range of machining tasks. They are larger than benchtop lathes and are commonly found in machine shops. The weight of engine lathes varies depending on their size, with smaller models weighing around 1,500 to 5,000 pounds (680 to 2,268 kilograms), while larger models can weigh anywhere from 10,000 to 40,000 pounds (4,536 to 18,144 kilograms).

3. CNC Lathe Machines

CNC lathe machines revolutionized the machining industry with their automated capabilities and precise control. These machines are capable of complex operations and can significantly reduce human error. CNC lathe machines are available in various sizes, from compact models to massive industrial-grade machines. The weight range can vary from a few thousand pounds to tens of thousands of pounds, depending on the size, construction, and additional features.

These are just a few examples of the types and weight ranges of lathe machines available. It’s crucial to evaluate your machining needs, available space, and budget before selecting the most suitable lathe machine for your specific requirements.

Understanding the Importance of Weight When Choosing a Lathe Machine

When it comes to lathe machines, weight plays a crucial role in their stability, accuracy, and overall performance. Here are a few reasons why weight should be considered when choosing a lathe machine:

1. Stability and Vibration Damping

A heavyweight lathe machine provides greater stability during machining operations. The weight helps dampen vibrations, ensuring smooth and precise cutting. This stability is especially important when working with challenging materials or executing complex operations.

2. Rigidity and Durability

A heavier lathe machine generally indicates a more robust and rigid construction. Rigidity is vital for maintaining accuracy and preventing deflection during cutting, especially when dealing with tough materials. The durability of the machine is also improved with a heavier construction, ensuring a longer lifespan and minimizing the need for repairs or replacements.

3. Operator Safety

The weight of a lathe machine also influences operator safety. A heavier machine reduces the risk of tipping or toppling during operation, providing a safer working environment. Additionally, the weight can absorb some of the vibrations and noise generated during machining, creating a more comfortable and less fatiguing experience for the operator.

In conclusion, the weight of a lathe machine depends on various factors, including size, type, construction materials, and additional components. Understanding the importance of weight in terms of stability, rigidity, and operator safety can help you make an informed decision when choosing a lathe machine. Consider your specific requirements and consult with experts to ensure you select the right machine for your needs. Happy machining!

Key Takeaways: How much does a lathe machine weigh?

- A lathe machine can weigh anywhere from a few hundred pounds to several thousand pounds.

- The weight of a lathe machine depends on its size and capacity.

- Smaller hobbyist lathes usually weigh around 100-200 pounds.

- Industrial lathes can weigh several thousand pounds or even tens of thousands of pounds.

- Transporting and moving a heavy lathe machine requires proper planning and equipment.

Frequently Asked Questions

Here are some common questions about the weight of lathe machines:

Q: How heavy is a typical lathe machine?

A: The weight of a lathe machine can vary depending on its size and design. On average, a small to mid-sized lathe machine can weigh anywhere from 500 to 2500 pounds, while larger industrial-grade machines can weigh several thousand pounds. It’s important to consider the weight of the lathe machine when setting up or moving it, as it may require special equipment or assistance.

When determining the weight of a specific lathe machine, it’s best to refer to the manufacturer’s specifications or consult the user manual. These resources should provide you with the accurate weight information for the particular model you are interested in.

Q: Why do lathe machines weigh so much?

A: The weight of a lathe machine is primarily due to its sturdy construction and the materials used in its manufacturing. Lathe machines are built to withstand heavy cutting forces and provide stability during operation. To achieve this, they are often made from high-quality cast iron or steel components, which adds to their overall weight.

The weight of a lathe machine is crucial for maintaining precision and reducing vibrations. The heavy mass helps dampen vibration caused by cutting tools and ensures the machine remains stable, resulting in accurate and quality machining. While the weight may make lathe machines challenging to move or transport, it is necessary for their functionality and performance.

Q: Can the weight of a lathe machine affect its performance?

A: Yes, the weight of a lathe machine can indeed impact its performance. The heavyweight of the machine provides stability, reducing vibrations during operation. This stability is crucial for achieving precise and accurate cuts. A lighter machine would be more prone to vibrations, which can result in poor surface finishes and compromised accuracy.

Additionally, the weight of the machine contributes to its rigidity. A sturdier lathe machine can handle heavier workpieces and endure higher cutting forces without flexing or deflecting. This rigidity ensures consistent and reliable performance, especially when working on challenging or demanding projects.

Q: Are there portable or lightweight lathe machine options available?

A: While most lathe machines are heavy due to their construction, there are portable or lightweight options available in the market. These machines are designed for specific purposes, such as hobbyist projects or small-scale machining. They may have smaller working capacities and lighter materials, making them easier to transport and set up.

However, it’s important to note that portable or lightweight lathe machines may have limitations in terms of their cutting capacity, power, and overall stability compared to larger and heavier industrial-grade machines. It’s essential to consider your specific machining needs and the type of projects you’ll be working on before deciding on a portable or lightweight lathe machine.

Q: Do all lathe machines weigh the same?

A: No, not all lathe machines weigh the same. The weight of a lathe machine can vary significantly based on various factors such as size, design, construction materials, and additional features. Smaller benchtop or mini-lathes will generally weigh less compared to larger, industrial-sized machines.

The weight of a lathe machine can also be influenced by its configuration, such as whether it includes additional accessories or attachments. For instance, a lathe machine with a turret tool post or an automatic bar feeder may have a slightly heavier weight compared to a basic lathe machine model without these features.

It’s crucial to consider your specific machining requirements when determining the appropriate weight and size of a lathe machine for your needs.

Summary

Lathes are heavy machines used to shape and cut materials like wood and metal. They come in different sizes and weights depending on their capacity and features. While smaller lathes may weigh around 150-300 pounds, larger industrial lathes can weigh several thousand pounds.

The weight of a lathe machine is essential to consider when purchasing or moving it, as it affects transportation and placement. It is crucial to consult the manufacturer’s specifications or seek professional help to ensure the machine’s weight is handled safely and efficiently.