Have you ever wondered how thin a table saw can cut? Well, you’ve come to the right place! In this article, we will dive into the fascinating world of table saws and explore just how thin these powerful tools can slice through materials.

When it comes to woodworking and DIY projects, table saws are essential for making precise and accurate cuts. Whether you’re crafting furniture or building a model, knowing the limitations of your table saw is crucial. So, let’s roll up our sleeves and find out how thin these mighty machines can go!

From slicing hardwood to cutting delicate veneers, table saws have the ability to make incredibly thin cuts with ease. But how thin exactly? Stay with us as we unleash the secrets of table saws and uncover the answer to the age-old question: how thin can a table saw cut?

So, grab your safety goggles and join us on this informative journey into the world of table saws. It’s time to unlock the potential of these mighty tools and discover just how thin they can cut. Let’s get started!

How Thin Can a Table Saw Cut?: Exploring the Possibilities

In the world of woodworking, table saws are indispensable tools. They allow us to make precise cuts, creating everything from furniture to artistic pieces. But have you ever wondered just how thin a table saw can cut? In this article, we will delve into the intricacies of table saws and uncover the minimum thickness they can achieve. Whether you’re a professional woodworker or a passionate hobbyist, understanding the capabilities of your tools is essential for pushing the boundaries of your craft.

Factors Affecting the Thickness of Table Saw Cuts

To determine how thin a table saw can cut, we must consider several factors that influence its performance. These factors include the blade type, saw setup, material properties, and operator skill. Let’s take a closer look at each of these factors and their impact on the final cut thickness.

The Blade Type

The type of blade you use plays a crucial role in determining how thin the table saw can cut. Generally, table saws are equipped with standard blades, which can typically achieve cuts as thin as 1/8 of an inch. However, if you require even thinner cuts, specialty blades like the thin-kerf blade or a dado set can be utilized. These blades have reduced thickness, allowing for cuts as thin as 1/32 of an inch, which is ideal for intricate woodworking projects or veneer applications.

Moreover, the number of teeth on the blade also affects the cut thickness. Blades with a higher tooth count produce finer cuts, while blades with fewer teeth are better suited for faster rip cuts. Consider the specific requirements of your project and choose a blade that meets your needs.

It’s crucial to note that while thin-kerf blades and dado sets can achieve thinner cuts, they may also result in a reduction in cutting power and a decrease in overall stability. Careful adjustment and proper technique are essential when working with these specialized blades.

Saw Setup and Configuration

The setup and configuration of your table saw are equally important for achieving thin cuts. Factors such as blade alignment, fence position, and zero-clearance inserts can significantly influence the final cut thickness.

First, ensure that your blade is properly aligned with the miter slots and the fence. Misalignment can cause the blade to exert uneven pressure, resulting in inconsistent and imprecise cuts. Regular blade maintenance, including periodic cleaning and sharpening, is also crucial for optimal cutting performance.

Next, the position of the fence relative to the blade determines the width of the cut. Carefully adjust the fence to achieve the desired thickness, taking into account the blade kerf width, which is the width of material the blade removes during cutting. Additionally, using zero-clearance inserts, which are custom throat inserts that reduce the gap between the blade and the tabletop, can minimize tear-out and improve the accuracy of thin cuts.

Material Properties

The properties of the material being cut can also impact how thin a table saw can cut. The hardness, density, and thickness of the material all play a role in determining the achievable cut thickness.

Softer materials, such as pine or cedar, are generally easier to cut to thinner dimensions compared to harder woods like oak or maple. Additionally, a thinner workpiece is more prone to vibration and deflection, which can affect the accuracy of the cut. Therefore, it’s essential to secure the material properly and use appropriate techniques to minimize these issues.

Overall, understanding the properties of the material and adapting your cutting approach accordingly will help you achieve the thinnest possible cuts with your table saw.

Operator Skill and Technique

Lastly, the skill and technique of the operator have a significant impact on the achievable cut thickness. Proper feeding techniques, consistent pressure, and precise control of the material are crucial for achieving thin cuts. It’s important to maintain a steady and smooth feed rate, avoiding any sudden or jerky movements that can lead to inaccurate cuts or accidents.

A seasoned woodworker with experience using a table saw will have a better understanding of the tool’s limitations and how to overcome them. Practice, patience, and continuous improvement of your skills will allow you to push the boundaries and achieve remarkable thin cuts with your table saw.

Key Takeaways: How Thin Can a Table Saw Cut?

- A table saw can cut as thin as the width of its blade, typically around 1/8 of an inch.

- Using a thin-kerf blade can allow for even thinner cuts, down to 1/16 of an inch.

- However, cutting material too thin can increase the risk of kickback, so caution is necessary.

- Proper blade alignment and stability are essential for accurate and safe thin cuts.

- Some specialized table saws and attachments can achieve even thinner cuts, but these are not commonly found in regular workshops.

Frequently Asked Questions

Welcome to our FAQ section where we answer common questions about table saws and their cutting capabilities. If you’re wondering how thin a table saw can cut, you’ve come to the right place. Find the answers you’re looking for below.

1. Can a table saw cut thin pieces of wood?

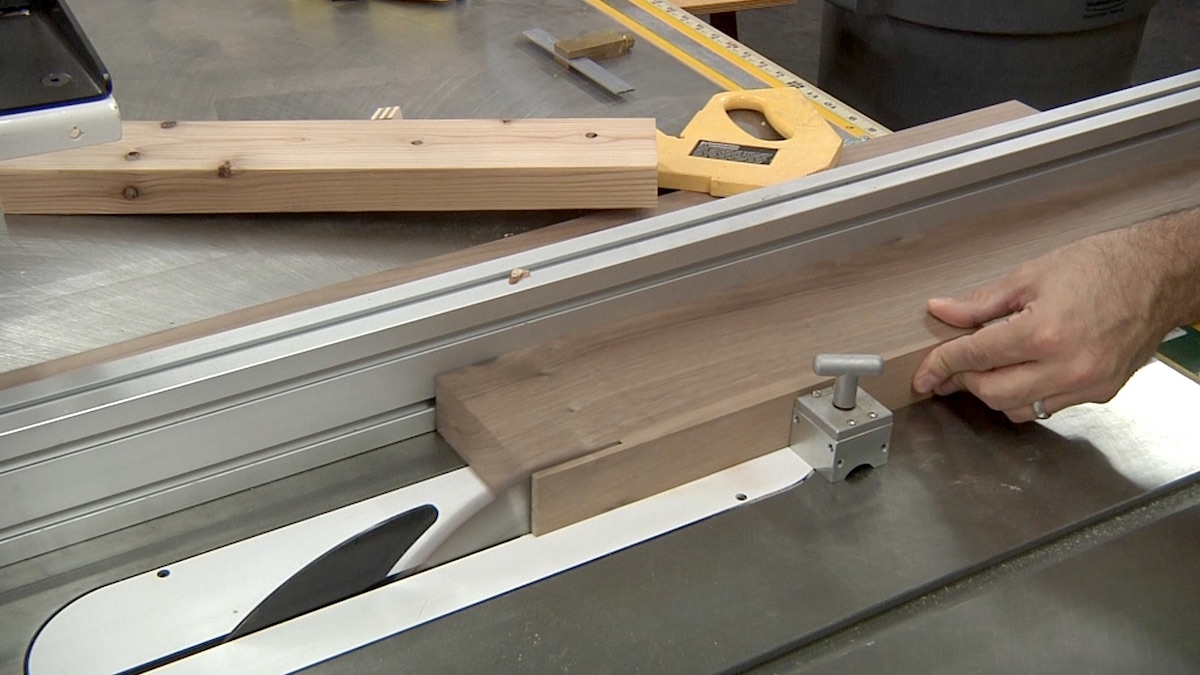

Yes, a table saw can cut thin pieces of wood, but it’s important to take safety precautions. Thin cuts may require extra care as the material can become unstable or prone to kickback. To ensure safer cuts, use a push stick or sled to guide the wood through the blade and always keep your hands a safe distance away from the blade. It’s also recommended to use a zero-clearance insert or a thin-rip jig to prevent the wood from splintering or binding.

Additionally, using a saw blade with more teeth can help achieve smoother cuts on thin pieces of wood. The appropriate blade width and type will depend on the thickness and hardness of the material you’re working with. Remember to always follow the manufacturer’s guidelines and recommendations for your specific table saw.

2. What is the thinnest cut a table saw can make?

The thinnest cut a table saw can make depends on various factors, including the saw’s design, blade type, and your cutting technique. In general, most table saws are capable of making cuts as thin as 1/8th of an inch or even thinner with the right blade and setup.

However, it’s important to note that making extremely thin cuts can be challenging and may require advanced techniques or specialized equipment such as a thin-rip jig or a dedicated thin-kerf blade. Always prioritize safety and consult the manufacturer’s guidelines to ensure you’re using your table saw within its recommended parameters.

3. Are there any limitations to how thin a table saw can cut?

While table saws are versatile tools, there are some limitations to consider when cutting thin materials. First, the stability of the material can be an issue. Thin pieces of wood or other materials may become unstable during the cutting process, potentially leading to inaccurate or unsafe cuts. Extra caution and proper support with push sticks or sleds are crucial in these scenarios.

Additionally, the capabilities of the blade and the saw itself play a role. Some table saws may have limitations on the minimum thickness they can effectively cut, depending on the design and specifications of the machine. It’s important to consult the user manual or contact the manufacturer for specific information about your table saw’s limits.

4. What safety measures should I take when cutting thin materials on a table saw?

When cutting thin materials on a table saw, it’s essential to prioritize safety. Here are some key precautions to take:

– Use a push stick or sled to keep your hands a safe distance from the blade.

– Ensure the material is properly supported and secured to prevent slipping or kickback.

– Consider using a zero-clearance insert or a thin-rip jig for smoother and safer cuts.

– Use appropriate personal protective equipment, such as safety glasses and hearing protection.

– Familiarize yourself with the operation and safety features of your specific table saw.

Remember, safety should always be your top priority when working with any power tool, especially when making cuts on a table saw.

5. Can a table saw cut materials other than wood?

Yes, table saws are versatile tools that can cut a wide range of materials, not just wood. With the right blade and setup, a table saw can cut materials like plastics, sheet metal, laminate, and even certain types of stone or tile. However, it’s important to choose the appropriate blade designed for the specific material you’re cutting and follow proper safety guidelines for each material.

Always check the manufacturer’s recommendations and guidelines to ensure your table saw is suitable for cutting non-wood materials. Some table saws may require special accessories or adjustments to handle different materials effectively and safely.

Cutting Thin Strips at Table Saw

Summary

Table saws can cut wood very thin, as thin as 1/8 of an inch.

However, cutting too thin may cause the wood to splinter or get stuck in the blade.

It is important to follow safety guidelines and use caution when cutting thin materials.

Some table saws have special blades or accessories for cutting thin stock, which can be useful.

Overall, with the right technique and equipment, table saws can cut wood to desired thicknesses.