Welcome, young DIY enthusiasts! Have you ever wondered how wide a table saw cut can be? Well, you’re in luck because today we’re going to dive into the fascinating world of table saws and their cutting capabilities.

If you’ve ever watched a handyman or carpenter at work, you might have noticed the precision and finesse with which they make their cuts. It’s like watching a magician perform tricks with wood! But have you ever wondered just how wide those cuts can be?

In this article, we’ll explore the factors that determine the width of a table saw cut and provide you with some handy tips on choosing the right saw for your projects. So, let’s buckle up and get ready to discover the secrets behind the width of a table saw cut!

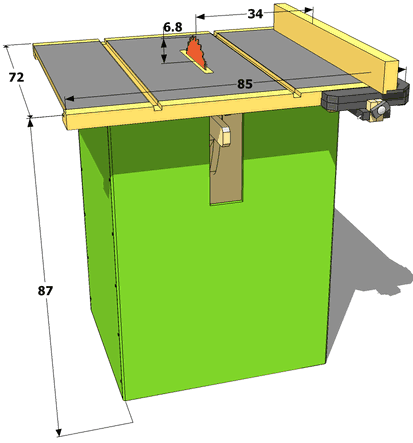

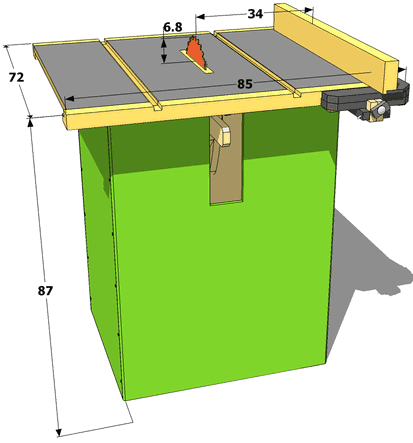

How Wide is a Table Saw Cut?

A table saw is an essential tool for woodworking and carpentry projects. Understanding the width of the cut that a table saw can make is crucial for achieving precise and accurate results. In this article, we will dive into the details of how wide a table saw cut can be, exploring different factors that affect the width and providing tips for achieving desired cuts. Whether you are a DIY enthusiast or a professional woodworker, this information will help you make the most of your table saw.

Factors Affecting the Width of a Table Saw Cut

When determining the width of a table saw cut, several factors come into play. Let’s take a closer look at these factors:

1. Blade Size

The size of the blade on your table saw significantly affects the width of the cut. Table saw blades come in various sizes, commonly ranging from 8 to 12 inches in diameter. The larger the blade, the wider the cut it can make. Generally, a 10-inch blade is the most versatile, allowing you to make a wide range of cuts.

It’s important to note that the width of the cut is limited to the diameter of the blade. For example, a 10-inch blade can make a maximum cut width of approximately 3 inches. If you need to make wider cuts, you may need to consider using a larger blade or using other cutting techniques.

2. Fence Positioning

The position of the fence on your table saw plays a crucial role in determining the width of the cut. The fence acts as a guide, keeping the workpiece aligned during the cutting process. By adjusting the fence, you can control the width of the cut.

Before making a cut, ensure that the fence is properly aligned parallel to the blade. This ensures that the cut is straight and accurate. Adjust the fence according to the desired width of the cut, ensuring that the workpiece is securely held in place.

3. Cutting Depth

The depth of the cut also affects the width of the cut on a table saw. By adjusting the cutting depth, you can control how deep the blade cuts into the workpiece. However, it’s important to note that the depth of the cut and the width of the cut are not directly proportional.

As a general rule, the maximum cutting depth of a table saw is equal to the diameter of the blade. For example, a 10-inch blade can typically cut up to a depth of 3 inches. However, the width of the cut may be less than the cutting depth due to factors such as the design of the blade gullets and the stability of the workpiece.

Tips for Achieving Desired Table Saw Cuts

Now that we have a better understanding of the factors that affect the width of a table saw cut, let’s explore some tips to help you achieve the desired cuts:

1. Measure and Mark

Precision is key when working with a table saw. Before making a cut, carefully measure and mark the dimensions on the workpiece. This will guide you in aligning the fence and setting the cutting depth accurately.

2. Use Proper Blade Types

Choosing the right blade for the desired cut is essential. Different blade types are designed for specific cutting applications. For example, a rip blade is ideal for making long cuts along the grain, while a crosscut blade is designed for cutting across the grain. Using the proper blade type ensures clean and accurate cuts.

3. Make Test Cuts

When working on a project that requires precise cuts, it’s always a good idea to make test cuts on scrap pieces of wood. This allows you to fine-tune the fence positioning, cutting depth, and blade selection before working on the actual project. Test cuts help minimize mistakes and ensure a high level of accuracy.

4. Use Safety Precautions

Table saws can be dangerous if not used properly. Always follow the manufacturer’s safety guidelines and wear appropriate safety gear, such as safety glasses and hearing protection. Additionally, ensure the table saw is positioned on a stable surface and the workpiece is firmly secured before making any cuts.

5. Consider Using Jigs and Guides

Jigs and guides can greatly enhance accuracy and precision when making table saw cuts. For example, a sled jig can help with crosscuts, while a miter gauge assists in making angled cuts. These accessories provide additional support and stability, resulting in cleaner and more consistent cuts.

By following these tips and understanding the factors that affect the width of a table saw cut, you can confidently and accurately make cuts on your table saw for various woodworking projects.

The Importance of Blade Maintenance and Replacement

Blade maintenance and replacement play a vital role in achieving clean and precise cuts on a table saw. Here are some key points to consider:

1. Keep the Blade Clean

Over time, sawdust and resin can accumulate on the blade, affecting its performance. Regularly clean the blade using a blade cleaner or mild detergent to remove any built-up debris. This ensures that the blade remains sharp and can make clean cuts.

2. Sharpen the Blade

As the blade dulls with use, it may start producing rough or splintered cuts. Sharpen the blade regularly to maintain its cutting performance. You can either sharpen the blade yourself using a sharpening stone or take it to a professional blade sharpening service.

3. Replace Worn-out Blades

Even with proper maintenance, blades eventually wear out and become ineffective. Signs of a worn-out blade include excessive vibration, burning marks on the workpiece, and poor quality cuts. Replace the blade with a new one to ensure optimal cutting performance and safety.

Remember, a well-maintained and sharp blade is essential for achieving accurate and clean cuts on a table saw.

Common Table Saw Cut Widths and Applications

Table saws are versatile tools that can make a wide range of cut widths to suit different woodworking needs. Here are some common table saw cut widths and their applications:

1. Rips

Rip cuts are made with the grain of the wood, resulting in long, narrow strips. A table saw is ideal for making rip cuts, and the width can be adjusted based on the desired project requirements. Common rip cut widths range from 1/8 inch to 24 inches or more.

2. Crosscuts

Crosscuts are made across the grain of the wood, creating shorter pieces. Table saws equipped with a miter gauge or crosscut sled can accurately make crosscuts of various widths. The width of crosscuts can range from a fraction of an inch to the maximum cutting capacity of the table saw.

3. Dadoes and Grooves

A dado is a wide, square-sided channel cut across the grain of the wood. Dadoes are commonly used for joinery and installing shelves. The width of a dado can be adjusted using a dado blade or a stack of multiple blades. It can range from a few millimeters to several inches.

4. Bevels and Angles

Table saws equipped with a tilting arbor can make beveled cuts at various angles. The width of a bevel cut is determined by the angle and the depth of the cut. Bevel cuts are commonly used for creating decorative edges and angled joints in woodworking projects.

These are just a few examples of the wide range of cut widths that can be achieved with a table saw. Understanding the applications and limitations of different cut widths allows you to approach woodworking projects with confidence and precision.

Conclusion

Understanding the width of a table saw cut is essential for achieving accurate and precise results in woodworking projects. Factors such as blade size, fence positioning, and cutting depth all play a role in determining the width of the cut. By following the tips mentioned in this article and considering the different applications of table saw cuts, you can confidently work with your table saw and achieve the desired results. Remember to prioritize safety and proper blade maintenance to ensure optimal cutting performance. Happy woodworking!

Key Takeaways

- A table saw can make cuts as wide as the distance between the blade and the fence.

- Table saw blades come in different sizes, affecting the maximum width of the cut.

- Using a thin-kerf blade allows for narrower cuts compared to a standard blade.

- Feeding the material slowly and steadily ensures an accurate and clean cut.

- It’s important to always wear appropriate safety gear when using a table saw.

Frequently Asked Questions

Welcome to our FAQ section, where we answer some of the most common questions about table saw cuts and their width. Below, you’ll find answers to help you understand the dimensions and variations of table saw cuts.

1. How wide can a table saw cut?

Table saws are capable of making cuts of varying widths, depending on the type of saw and the blade being used. In general, a standard table saw equipped with a standard blade can make cuts up to 3 inches wide. However, with specialized blades, such as dado blades or rip blades, wider cuts can be achieved. It’s essential to refer to your specific table saw’s user manual for guidance on the maximum cut width it can handle.

Keep in mind that achieving wider cuts requires adjusting the blade height and potentially using additional accessories or attachments. Always prioritize safety when making wider cuts, ensuring you follow proper procedures and use appropriate protective gear.

2. Can a table saw make narrower cuts?

Yes, table saws can make narrower cuts by adjusting the fence or using a narrower blade. The fence is a guide that determines the distance between the blade and the edge of the material being cut. By moving the fence closer to the blade, you can make narrower cuts. Additionally, using a narrow-kerf blade, specifically designed for thinner cuts, will help achieve narrower results.

However, please note that when making narrower cuts, it’s important to take precautions to prevent kickback, which is the sudden and forceful movement of the material being cut. Always use a push stick or push block to keep your hands safe and maintain control of the workpiece.

3. Are there limitations to the width of table saw cuts?

While table saws are versatile tools, there are limitations to the width of cuts they can make. The primary limitations depend on the size of the blade and the capacity of the table saw. Standard blades typically range from 10 to 12 inches in diameter, and larger blades can handle wider cuts. However, oversized cuts may require specialized equipment or different cutting methods.

It’s important to consider the power and capabilities of your table saw when determining the width of cuts you plan to make. Additionally, some thicker or denser materials may be more challenging to cut with a table saw, and alternative cutting tools may be more suitable for those instances.

4. What factors affect the width of a table saw cut?

Several factors can affect the width of a table saw cut. The main factors include the size of the blade, the width of the material being cut, and the cutting capacity of the table saw. Additionally, the type of blade used, such as a standard blade, dado blade, or rip blade, can also influence the width of the cut.

It’s crucial to choose the right blade and adjust the settings of your table saw accordingly to achieve the desired width of the cut. Always refer to the manufacturer’s instructions and follow recommended safety guidelines for your specific table saw model.

5. Can I make multiple passes to achieve a wider table saw cut?

Yes, it’s possible to make multiple passes to achieve a wider table saw cut. This technique is commonly used when cutting thicker materials or when the table saw’s cutting capacity is limited. By making several passes with progressively wider cuts, you can achieve the desired width. However, it’s crucial to ensure that each cut is properly aligned and that you maintain control of the workpiece during each pass.

When making multiple passes, take extra care to ensure accurate alignment and avoid making the subsequent cuts too deep, which can cause kickback or damage to the material. It’s also important to consider the additional time and effort required when planning your project.

Summary

Table saws can make different width cuts depending on the size of the blade. The blade’s diameter determines the maximum cut width, so a larger blade can make wider cuts. It’s important to choose the right blade size for your project to ensure you get the desired cut width. Additionally, you can adjust the fence, which is a guide that helps you make straight cuts, to control the width of the cut even further. Remember to always follow safety guidelines when operating a table saw.

Overall, understanding the width of a table saw cut involves considering the blade size and adjusting the fence. By doing so, you can achieve the desired cut width for your woodworking projects while staying safe. Happy woodworking!