Are you curious about what power tools carpenters use? Well, if you’ve ever wondered how they bring their woodworking projects to life, you’re in the right place! In this article, we’re going to delve into the world of carpentry and explore the essential power tools that carpenters rely on to turn raw materials into stunning creations. So, let’s get started and uncover the tools that make carpentry a true work of art!

When it comes to carpentry, power tools are like a carpenter’s trusted sidekicks. These tools make tasks easier, faster, and more efficient, allowing carpenters to bring their visions to life with precision and finesse. From sawing through thick timber to shaping intricate details, power tools give carpenters the ability to transform their raw materials into masterpieces.

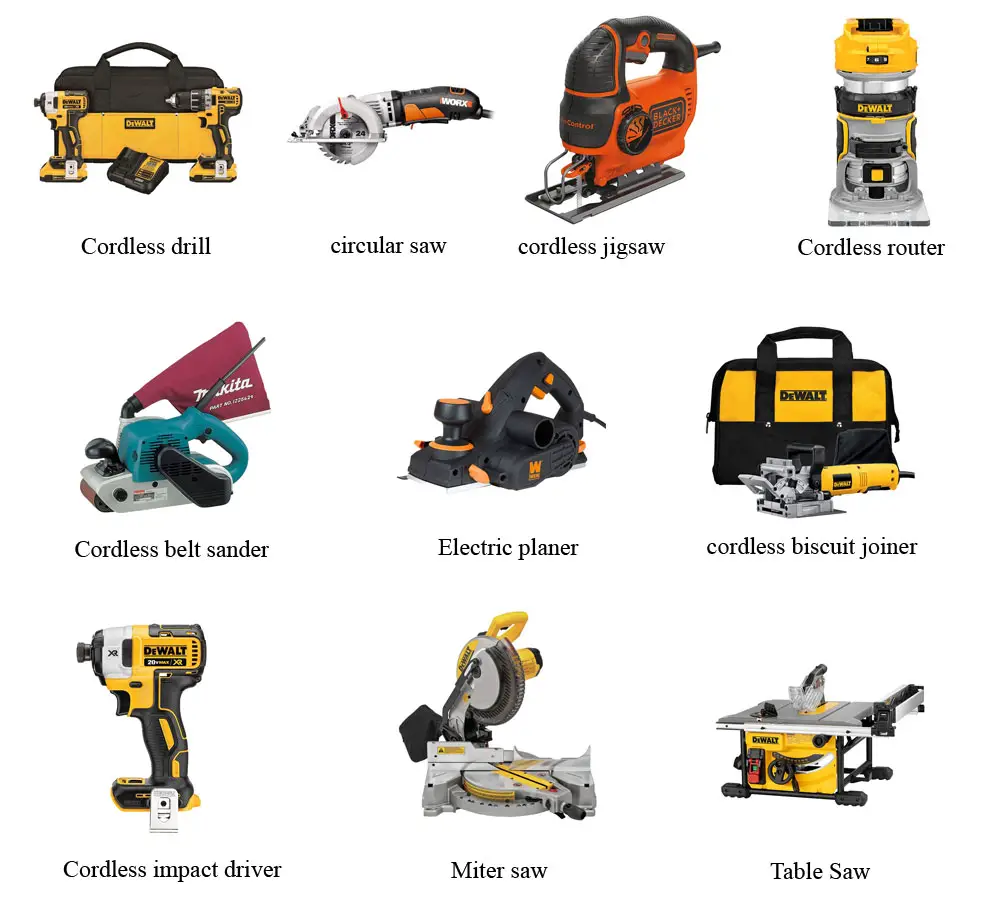

So, what power tools do carpenters use? Well, brace yourself because we’re about to embark on a journey through a carpenter’s toolbox! From the versatile circular saw and mighty power drill to the detail-oriented jigsaw and robust router, each power tool has its own special role in the carpenter’s arsenal. By mastering these tools, carpenters can tackle any woodworking project that comes their way. So, let’s dive in and explore the magical world of power tools for carpentry!

:max_bytes(150000):strip_icc()/power-tools-woodworkers-should-have-3536541-FINAL1-5bb7c2bc46e0fb002692907b.png)

What Power Tools Do Carpenters Use?

Introduction: Carpentry is a skilled trade that involves shaping and constructing various structures with the use of wood. To achieve precision and efficiency in their work, carpenters rely on a range of power tools that are specially designed for their craft. These tools not only save time, but they also enhance the quality and accuracy of the carpenter’s work. In this article, we will explore the essential power tools that carpenters use on a regular basis, along with their functions and benefits.

1. Circular Saw

A circular saw is one of the most versatile and frequently used power tools by carpenters. It consists of a round blade that spins rapidly to make accurate straight cuts in various materials, including plywood, lumber, and even metal. Carpenters use circular saws for tasks such as cutting lengths of wood for framing, ripping boards, and making crosscuts. The compact size and portability of circular saws make them indispensable on job sites where space and mobility are crucial.

Circular saws offer several advantages to carpenters. They provide precise and controlled cutting, thanks to their adjustable cutting depth and angle. The blades can be easily replaced to accommodate different materials, and they can also be tilted for beveled cuts. Additionally, circular saws feature safety mechanisms such as blade guards and electric brakes, enhancing user protection and reducing the risk of accidents.

Carpenters should consider investing in a high-quality circular saw with features like a powerful motor, an ergonomic handle for comfort, and a durable construction. Regular maintenance, such as blade sharpening and lubrication, will ensure optimal performance and prolong the lifespan of the tool.

2. Power Drill

The power drill is another indispensable tool for carpenters, enabling them to perform a wide range of tasks efficiently. Whether it’s drilling holes or driving screws, a power drill offers versatility and convenience. Corded drills provide consistent power, whereas cordless drills offer portability and flexibility on the job site, especially when access to electricity is limited. Carpenters often use power drills to install hardware, assemble furniture, and secure materials together.

Power drills come with a variety of features and options to suit different carpentry needs. Key considerations include the drill’s speed settings, torque (driving power), battery life (for cordless models), and chuck size (to accommodate various drill bits). Some advanced drills even offer additional functionalities such as hammer drilling and impact driving, expanding their capabilities in tougher materials or fastening applications.

Caring for a power drill involves regular maintenance, such as cleaning the chuck and changing the drill bits when needed. It’s also essential to keep the drill’s battery charged or replace it as necessary, ensuring uninterrupted usage on the job site.

3. Miter Saw

A miter saw is a specialized power tool that carpenters rely on for making accurate angled cuts, also known as miter cuts and bevel cuts. It consists of a circular blade mounted on a pivoting arm, allowing the carpenter to adjust the angle and make precise cuts at various degrees. Miter saws are commonly used in tasks such as cutting moldings, trim work, and framing components.

Carpenters appreciate the efficiency and accuracy that miter saws offer. These power tools come with features like preset angles for common cuts and adjustable stops for repetitive accuracy. Some models also include a sliding mechanism that increases the cutting capacity, enabling the carpenter to handle larger workpieces. Safety features such as blade guards and a dust collection system help maintain a clean and safe work environment.

When selecting a miter saw, carpenters should consider factors like blade size, cutting capacity, and the presence of a laser guide for improved precision. Regularly cleaning the saw and ensuring the blade is sharp will optimize its performance and deliver clean and accurate cuts.

4. Router

A router is a versatile power tool that is essential for shaping wood and cutting precise grooves, edges, or patterns. Carpenters use routers for tasks such as creating decorative molding, cutting dadoes and rabbets, and even crafting intricate designs. Routers come in two types: plunge routers, which allow the bit to be adjusted vertically during operation, and fixed-base routers, which have a stationary bit position.

Routers offer several benefits to carpenters. They provide the ability to work with different profiles and shapes, thanks to a wide selection of router bits available. Routers also allow for precise and fine adjustments to achieve the desired results. Some advanced routers have features like variable speed control and dust collection systems, enhancing user comfort and safety.

When selecting a router, carpenters should consider factors like the power of the motor, the type and availability of router bits, and the ease of depth adjustment. Proper maintenance includes regular cleaning, ensuring bit sharpness, and lubricating the router’s moving parts.

5. Random Orbital Sander

A random orbital sander is a power tool that carpenters use to achieve smooth and flawless finishes on wood surfaces. Unlike traditional sanders, the random orbital sander moves in an elliptical pattern, reducing visible sanding marks and providing a superior finish. Carpenters use this tool for tasks such as sanding furniture, preparing surfaces for painting or staining, and removing old finishes.

Random orbital sanders offer several advantages. They provide a fast and efficient sanding process, thanks to their high-speed rotation and random orbit pattern. The sanding pads are available in various grits, allowing carpenters to achieve different levels of smoothness. Additionally, many models come with features like built-in dust collection systems to minimize dust in the work area and improve air quality.

When purchasing a random orbital sander, carpenters should consider factors like the tool’s power, sanding pad size, and the availability of sanding discs. Regularly cleaning the sander and replacing worn-out sanding pads will ensure optimal performance and consistent results.

6. Reciprocating Saw

A reciprocating saw, also known as a saber saw or a recip saw, is a power tool that carpenters use for various demolition and rough cutting tasks. This saw features a straight blade that moves back and forth rapidly, allowing for aggressive cutting in materials such as wood, metal, plastics, and even masonry. Carpenters commonly use reciprocating saws for tasks such as cutting through framing components, removing old fixtures, and creating openings.

The reciprocating saw offers versatility and power, making it a valuable addition to a carpenter’s toolkit. Its long blade allows for cuts in challenging and hard-to-reach areas. Some models offer variable speed control to adjust the cutting speed based on the material being cut. Additionally, certain blades can be chosen specifically for different materials, allowing for efficient and precise cutting.

Caring for a reciprocating saw involves regularly cleaning the tool and changing the blades when they become dull or damaged. Proper usage of safety gear, such as goggles and gloves, is essential to protect against debris and ensure a safe working environment.

7. Brad Nailer

A brad nailer is a power tool that carpenters use to drive thin nails, called brads, into wood materials. It offers convenience and speed when it comes to tasks such as installing trim work, assembling cabinets, and attaching molding. Brad nailers come in pneumatic (air-powered), electric, and cordless versions, providing options depending on the carpenter’s needs and preferences.

The benefits of using a brad nailer include reduced hammering time, increased accuracy, and minimized risk of damaging delicate materials. These nailers are lightweight and easy to maneuver, allowing for precise nail placement. Some models also offer features like depth adjustment for consistent nail depth and a jam-clearing mechanism for uninterrupted operation.

When selecting a brad nailer, carpenters should consider factors like nail size compatibility, magazine capacity, and the availability of accessories such as carrying cases and extra batteries. Regularly cleaning the nailer, lubricating its moving parts, and using the correct nail sizes will ensure optimal performance and prevent jams.

Using Power Tools Safely

It’s crucial to prioritize safety while using power tools as a carpenter. Here are some important tips to keep in mind:

1. Wear Appropriate Safety Gear

Always wear safety glasses to protect your eyes from flying debris. Use ear protection in noisy environments and wear a dust mask to prevent inhalation of harmful dust particles. Additionally, consider wearing gloves to protect your hands and closed-toe shoes for foot safety.

2. Read and Follow the Tool’s Manual

Before operating any power tool, read the instruction manual thoroughly to understand its features, limitations, and safety procedures. Adhere to the manufacturer’s guidelines and recommendations to prevent accidents.

3. Maintain a Clean and Organized Work Area

Keep your work area free from clutter, tripping hazards, and excess dust. Ensure proper lighting to enhance visibility and minimize accidents while operating power tools.

4. Use Tools in Well-Ventilated Areas

When using power tools that produce fumes or dust, make sure you have proper ventilation to prevent the build-up of hazardous substances. If necessary, wear a respirator to protect your respiratory system.

5. Secure Workpieces Properly

Always secure the workpiece firmly in place before operating any power tool. Use clamps or other appropriate methods to prevent the piece from moving or shifting during use.

6. Disconnect Power Sources Before Adjustments

Whenever making adjustments or changing accessories on a power tool, ensure that it is disconnected from the power source. This prevents accidental starting or operation while your hands are near the tool’s moving parts.

7. Regularly Inspect and Maintain Tools

Perform routine inspections on your power tools to identify any wear and tear or damage. Keep them clean and lubricated according to the manufacturer’s recommendations. Replace worn-out parts promptly to maintain optimal performance and safety.

By following these safety guidelines, carpenters can ensure a safer working environment and reduce the risk of accidents or injuries while using power tools.

Key Takeaways: What Power Tools do Carpenters Use?

1. Power Drill: Carpenters use power drills to bore holes and drive screws into wood.

2. Circular Saw: This tool helps carpenters make straight and angled cuts on various wood materials.

3. Jigsaw: Carpenters use jigsaws to make intricate and curved cuts in wood.

4. Router: This tool is used to shape and create decorative edges on wooden surfaces.

5. Nail Gun: Carpenters use nail guns to quickly and efficiently secure wood pieces together.

Frequently Asked Questions

Here are some common questions about the power tools used by carpenters:

1. What are the essential power tools for carpenters?

The essential power tools for carpenters include a circular saw, a power drill, a jigsaw, a table saw, and a router. These tools allow carpenters to efficiently cut, drill, shape, and join wood for various construction and woodworking projects.

The circular saw is perfect for making straight cuts, while the jigsaw is used for cutting curves and intricate designs. A power drill is necessary for drilling holes and driving screws, and a table saw is ideal for making precise cuts. A router helps with shaping edges and creating decorative profiles.

2. What is the main purpose of a miter saw in carpentry?

A miter saw, also known as a chop saw, is a power tool commonly used in carpentry for cutting precise angles. Its main purpose is to make accurate crosscuts and miter cuts. Carpenters use a miter saw when working on projects that require precise and clean angled cuts.

Whether cutting baseboards, crown molding, or making frames, the miter saw allows carpenters to achieve consistent and professional-looking results. Its adjustable cutting angles and sharp blade make it an essential tool for carpenters seeking precision and efficiency in their work.

3. How does a planer help carpenters?

A planer is a power tool used to smooth and level the surface of wood. It works by shaving off thin layers of wood, resulting in a uniformly flat and smooth finish. Carpenters use planers to remove imperfections, roughness, and unevenness from wooden surfaces.

By utilizing a planer, carpenters can take rough-sawn lumber and transform it into perfectly smooth and even boards. This makes it an indispensable tool for achieving the desired finish and dimension when working on projects like furniture, cabinets, and flooring.

4. What role does a nail gun play in carpentry?

A nail gun, also referred to as a nailer, is a power tool designed to quickly drive nails into wood without the need for a traditional hammer. It simplifies the process of fastening wood by providing rapid, accurate, and consistent nail placement.

For carpenters, a nail gun increases efficiency and productivity by eliminating the manual effort required to drive nails. It is commonly used for framing, installing baseboards, attaching trim, and other construction tasks where secure and efficient fastening is needed.

5. How can a power sander benefit carpenters?

A power sander is a tool used to smooth surfaces by rapidly sanding away roughness, paint, or other materials. It saves carpenters time and effort compared to hand sanding, ensuring a more uniform and even finish.

Carpenters rely on power sanders to prepare surfaces for painting, staining, or applying finishes. It helps remove scratches, imperfections, and old coatings from wood, leaving it ready for the desired treatment. The various types of power sanders include orbital sanders, belt sanders, and detail sanders, each suitable for different tasks and surfaces.

Top 10 Best PowerTools for Woodworking and Carpentry

Summary

So, now you know all about the power tools that carpenters use. They have different tools for cutting, shaping, joining, and drilling. These tools help them create amazing things out of wood and make their work easier. Whether it’s a circular saw, a power drill, or a router, these tools are essential for carpenters to bring their ideas to life. So, if you ever decide to become a carpenter, make sure to have these power tools in your toolbox!

Remember, safety is always the top priority when using power tools. Always wear protective gear and follow the instructions carefully to avoid accidents. And don’t forget, practice makes perfect, so keep honing your skills and creating wonderful things with these power tools. Happy woodworking!