When it comes to using a table saw, one tool that can make your woodworking projects safer and more precise is a table saw sled. But how wide should a table saw sled be? In this article, we’ll explore the optimal width for a table saw sled and why it’s important for your woodworking endeavors. So let’s dive in and find out the perfect width for your table saw sled!

Having the right width for your table saw sled is crucial for ensuring stability and accuracy in your cuts. When the sled is too narrow, it may not provide enough support for your workpiece, leading to wobbly cuts and potential safety hazards. On the other hand, if the sled is too wide, it may impede the movement of the workpiece, hindering your ability to make precise cuts.

The ideal width for a table saw sled depends on a few factors, including the size of your table saw and the type of cuts you often make. By striking the right balance between stability and maneuverability, you can determine the perfect width for your table saw sled. So, let’s explore the different considerations and find out the optimal width for your table saw sled!

When determining the width of a table saw sled, there are a few factors to consider. Firstly, the width should be wide enough to provide stability for your workpiece. A good rule of thumb is to make it slightly wider than the widest workpiece you plan to cut. Additionally, it’s important to ensure that the sled fits comfortably on your table saw’s surface. Take measurements and consider the space you have available. Ultimately, the width should be practical and allow for safe and efficient use of your table saw sled.

How Wide Should a Table Saw Sled Be?

When it comes to using a table saw, a sled is a handy accessory that can greatly enhance the safety and accuracy of your cuts. A table saw sled is essentially a sliding platform that allows you to guide your workpiece through the blade with precision and control. One common question that woodworkers often ask is, “How wide should a table saw sled be?” In this article, we will explore the factors to consider when determining the width of a table saw sled and provide some helpful tips to ensure optimal performance.

The Importance of Choosing the Right Width

Choosing the right width for your table saw sled is crucial for several reasons. Firstly, the width directly affects the stability of the sled. A wider sled generally offers more stability and reduces the chances of tipping or wobbling during use. Secondly, the width determines the maximum size of workpieces that can be safely and effectively cut using the sled. A sled that is too narrow may not provide enough surface area to support larger workpieces, compromising both safety and accuracy. On the other hand, a sled that is too wide can hinder maneuverability and make it challenging to make precise cuts.

Additionally, the width of the sled should be compatible with the size of your table saw’s miter slots. The miter slots are the channels on the table saw surface where the sled rides. If the sled is too wide, it may not fit properly in the miter slots, resulting in instability and poor performance. Conversely, a sled that is too narrow in relation to the miter slots can lead to misalignment and inaccurate cuts. Therefore, it is essential to choose a sled width that matches and properly fits the miter slots on your table saw.

Factors to Consider in Determining the Width

Now that you understand the importance of choosing the right width for your table saw sled, let’s delve into the factors you should consider when determining the appropriate size:

Sled Stability:

As mentioned earlier, the width of the sled directly affects its stability. A wider sled offers a larger contact area with the table saw surface, which helps distribute the weight of the workpiece more evenly. This ensures greater stability when making cuts and reduces the risk of tip or wobble. However, it’s important to strike a balance and avoid excessive width that could hinder maneuverability.

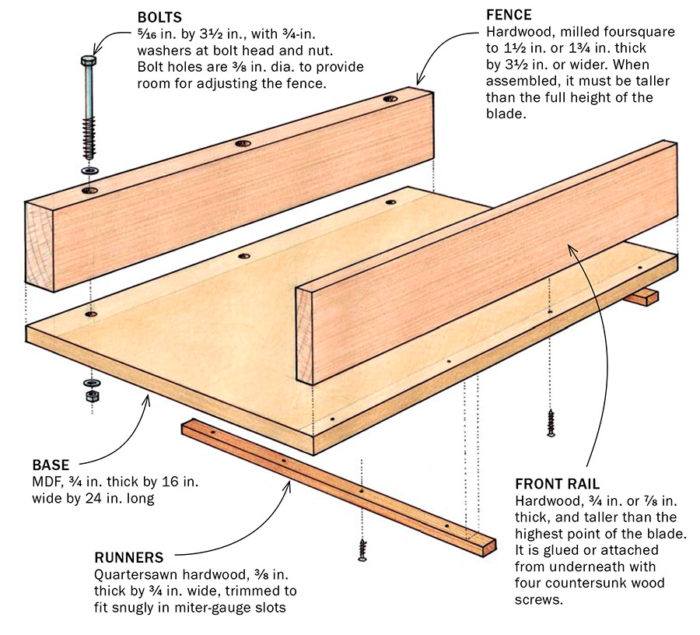

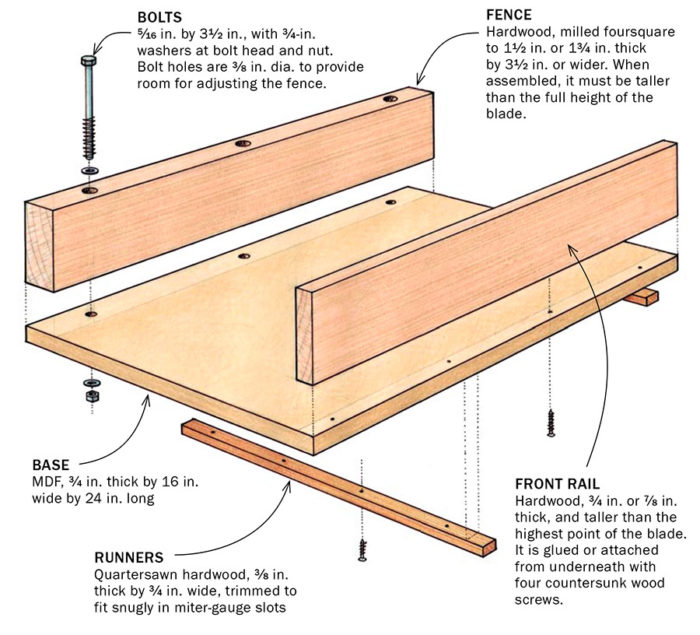

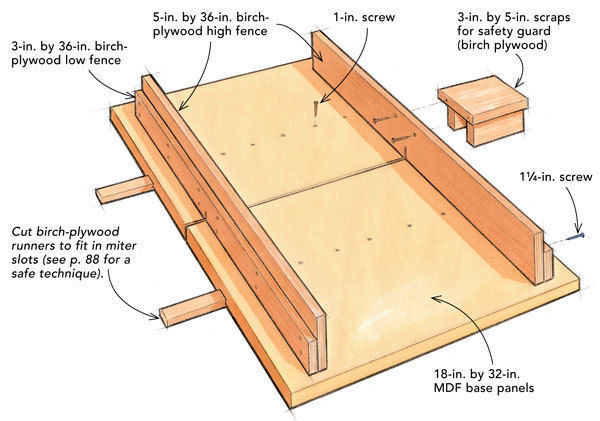

Another consideration for stability is the thickness and rigidity of the sled’s base material. Thicker and more rigid materials, such as plywood or solid wood, can support wider sleds more effectively than thinner materials like MDF. Therefore, while determining the sled width, take into account the material you plan to use for the sled’s base.

Workpiece Size:

The width of your sled should accommodate the maximum size of workpieces you typically need to cut. Consider the length, width, and thickness of your workpieces, and ensure that the sled provides enough support and surface area to safely handle them. It is advisable to add some extra width to account for future projects that may involve larger workpieces.

Additionally, remember to consider any joinery or cutting techniques that may require extra space. For example, if you often make box joints or finger joints, you will require additional width to maneuver the workpiece and guide it through the blade.

Miter Slot Compatibility:

The width of the sled should be compatible with the miter slots on your table saw. Measure the distance between the miter slots and choose a sled width that fits snugly within this range. The sled should slide smoothly and snugly through the miter slots without any play or excessive tightness. If the sled is too wide or too narrow in relation to the miter slots, it can lead to instability and inaccurate cuts.

Some table saws come with adjustable miter slots that allow you to fine-tune the fit of the sled. If your table saw has this feature, take advantage of it to ensure the best fit for your sled.

Tips for Optimizing Your Table Saw Sled

Now that you have a better understanding of how to determine the width of your table saw sled, here are a few additional tips to optimize its performance:

1. Use High-Quality Materials:

Choose sturdy and durable materials for your sled to ensure longevity and accuracy. Select high-quality plywood or solid wood for the base, and use hardwood for the runners that slide through the miter slots.

2. Enhance Safety:

Consider adding safety features such as toggle clamps or hold-downs to secure the workpiece firmly to the sled. This will minimize the risk of kickback and ensure a secure grip during cuts.

3. Smooth Runners:

Ensure that the runners on the sled’s base slide smoothly through the miter slots. Sand them down and apply a lubricant, such as beeswax, to reduce friction and enhance the sled’s maneuverability.

4. Regular Maintenance:

Periodically inspect and maintain your table saw sled to keep it in optimal condition. Check the runners for wear and tear and replace them if needed. Also, ensure that the base is flat and free from warping or bowing.

5. Practice Safe Techniques:

Lastly, always follow proper safety techniques when using your table saw sled. Keep your hands clear of the blade, wear appropriate safety gear, and use push sticks or push blocks to guide the workpiece through the blade. Familiarize yourself with the user manual and guidelines provided by the manufacturer to ensure safe and efficient operation.

By considering these tips and choosing the right width for your table saw sled, you can enjoy improved accuracy, stability, and safety when working with your table saw. Remember to prioritize your specific needs and preferences while ensuring compatibility with your table saw’s miter slots. With a well-built and properly sized sled, you’ll be able to tackle a wide range of woodworking projects with confidence and precision.

Key Takeaways: How wide should a table saw sled be?

- A table saw sled should have a width that allows for stability and accuracy in cutting.

- A good rule of thumb is to make the sled wider than the widest board you plan on cutting.

- A wider sled provides more surface area for support and helps prevent wood from tipping or shifting during the cut.

- However, a sled that is too wide may become cumbersome to handle and maneuver.

- Consider the size of your work area and the type of projects you will be working on to determine the ideal width for your table saw sled.

Frequently Asked Questions

Are you wondering how wide your table saw sled should be? Well, you’ve come to the right place! We’ve compiled some common questions about table saw sled width and provided detailed answers to help you make an informed decision.

1. What factors should I consider when determining the width of my table saw sled?

When deciding how wide your table saw sled should be, there are a few key factors to keep in mind. First, consider the size of the workpiece you typically work with. Your sled should be wide enough to accommodate the largest piece you typically cut. Additionally, consider the stability of your sled. A wider sled will generally provide greater stability and control, especially when cutting larger or heavier materials. Finally, take into account the available space in your workshop. Ensure the sled isn’t too wide that it becomes impractical to maneuver around your workspace.

In summary, when determining the width of your table saw sled, consider the size of your workpiece, the desired stability, and the available space in your workshop.

2. Can a table saw sled be too wide?

While there isn’t a definitive answer to this question, a table saw sled can indeed be too wide in certain situations. If your sled is excessively wide, it may become challenging to maintain control and accuracy in your cuts. The wider the sled, the more effort it may require to push and guide it through the cut. Additionally, an overly wide sled can be cumbersome and difficult to maneuver, especially in smaller workshop spaces.

Ultimately, it’s important to find a balance between the width of the sled and your specific needs. Consider the size of your workpiece, the weight of the materials you typically work with, and the available space in your workshop when determining the width of your table saw sled.

3. Are there any standard sizes for table saw sleds?

There is no one-size-fits-all answer to this question, as the ideal size for a table saw sled can vary depending on individual needs and preferences. However, there are some common guidelines that can help you determine a suitable size. For rectangular table saw sleds, a popular width range is typically between 10 to 16 inches. This range allows for stability and ease of use while accommodating various workpiece sizes.

Keep in mind that these dimensions are just general guidelines, and you may need to adjust the width based on your specific requirements. It’s crucial to consider factors like the size of your workpiece, the materials you work with, and the space in your workshop to determine the best width for your table saw sled.

4. Can I modify the width of my existing table saw sled?

Absolutely! Modifying the width of your table saw sled is entirely possible and can be a great way to tailor it to your specific needs. If you find that your sled is too wide or narrow for your preference, you can easily adjust it. One common method is to trim down the sled’s width by cutting off excess material. Alternately, you can add additional width by attaching wider pieces to the existing sled. However, ensure that any modifications you make maintain the stability and accuracy of the sled.

Remember to take caution and measure carefully when modifying your sled’s width. It’s also essential to double-check that the changes don’t interfere with any other components of your table saw or compromise safety.

5. Can I use multiple sleds with different widths?

Yes, using multiple sleds with different widths can be a practical solution for cutting various sizes of workpieces. Having multiple sleds allows you to choose the most suitable sled for a particular project, providing better stability and control. For example, you might have a narrower sled for cutting smaller pieces and a wider sled for larger projects.

Keeping multiple sleds with different widths allows you to maximize precision and efficiency in your woodworking projects. Just ensure you have space in your workshop to store the additional sleds, and maintain their stability and functionality over time.

Summary

When making a table saw sled, it’s important to consider the width of the sled. The width should be wide enough to provide stability, but not too wide that it becomes cumbersome to use. A good rule of thumb is to make the sled about 1/3 to 1/2 the width of your table saw’s fence.

Another key point to keep in mind is to ensure that the sled is parallel to the blade to ensure accurate cuts. Using a tape measure and a shim, you can easily align the sled with the blade before securing it in place.

In conclusion, when building a table saw sled, aim for a width that provides stability without being too wide, and ensure it is parallel to the blade for accurate cuts.