Have you ever wondered, “Is exposure 1 plywood?” Well, you’ve come to the right place! In this article, we’re going to explore the world of plywood and uncover the truth about exposure 1 plywood. So sit tight, because we’re about to embark on a journey of knowledge and discovery!

Now, you might be thinking, “What exactly is exposure 1 plywood?” Great question! Exposure 1 plywood is a type of plywood that is specifically designed for temporary exterior construction purposes. It is made with a special adhesive that allows it to withstand exposure to moisture and weather conditions for a limited period of time.

But here’s the thing – exposure 1 plywood is not meant to be a permanent solution. It’s like the superhero of plywood, swooping in to save the day during construction projects, but not sticking around for the long haul. So if you’re considering using plywood for a more permanent application, exposure 1 might not be your best bet.

So there you have it – a glimpse into the world of exposure 1 plywood. In the next sections, we’ll dive deeper into its uses, benefits, and limitations. So buckle up and get ready to become a plywood expert! Let’s explore the fascinating world of exposure 1 plywood together.

Is Exposure 1 Plywood? Exploring the Different Types and Uses

Plywood is a versatile material commonly used in construction and woodworking projects. One question that often arises is whether exposure 1 plywood is a valid type. In this article, we will delve into the world of plywood and uncover the truth about exposure 1 plywood. From its definition and characteristics to its uses and benefits, we will provide you with a comprehensive guide.

What is Exposure 1 Plywood?

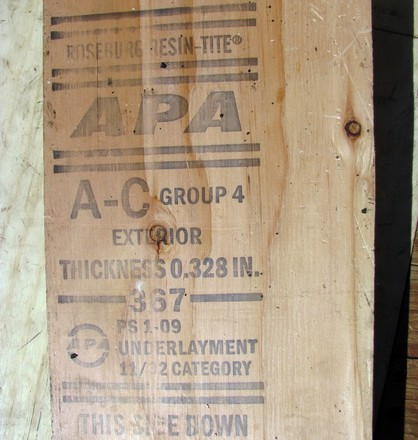

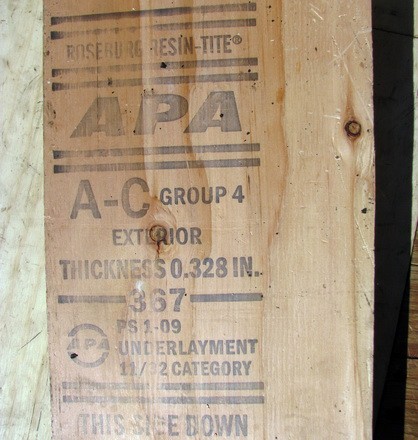

Exposure 1 plywood refers to a specific type of plywood that is designed for applications where exposure to weather or moisture is expected, but not intended to be permanent. This is indicated by the “Exterior” or “Exposure 1” grade stamp on the plywood. This grade identifies plywood that can withstand moderate levels of moisture, making it suitable for use in damp or humid environments.

Exposure 1 plywood is made using weather-resistant adhesives that provide a strong bond between the layers of wood veneer. This adhesive is specially formulated to withstand moisture, ensuring that the plywood remains structurally sound even when exposed to rain or humidity. However, it is important to note that exposure 1 plywood should not be used in applications where it will be in direct contact with water for extended periods, as it is not designed to be waterproof.

The Advantages of Exposure 1 Plywood

Exposure 1 plywood offers several advantages that make it a popular choice in construction and woodworking projects. Firstly, its exterior grade adhesive provides enhanced durability and strength, ensuring that the plywood can withstand the rigors of outdoor use. This makes it suitable for applications such as sheathing, roofing, and subflooring.

Additionally, exposure 1 plywood is more resistant to moisture compared to interior grade plywood. While it is not fully waterproof, it can withstand moderate exposure to moisture without warping or delaminating. This makes it a reliable choice for projects where a certain level of moisture resistance is required.

Furthermore, exposure 1 plywood is widely available and cost-effective, making it a practical choice for both professional builders and DIY enthusiasts. Its versatility and affordability make it a go-to material for a wide range of projects, from sheds and furniture to temporary structures and signage.

Applications of Exposure 1 Plywood

Exposure 1 plywood finds applications in various industries and projects. Its weather-resistant properties make it suitable for outdoor applications where exposure to moisture is expected but not constant. Some common uses of exposure 1 plywood include:

- Exterior sheathing and structural panels

- Dormers and roof overhangs

- Siding and cladding

- Sheds and outbuildings

- Temporary structures, such as construction site barriers

It is important to note that exposure 1 plywood is not recommended for use in applications that require constant exposure to water, such as submerged marine use or permanent outdoor installations. In such cases, marine grade or pressure-treated plywood would be more suitable.

Exposure 1 Plywood vs. Other Types

When comparing exposure 1 plywood to other types of plywood, it is essential to understand the differences in their intended applications and characteristics. Here are some key comparisons:

| Type of Plywood | Intended Use | Water Resistance |

|---|---|---|

| Exposure 1 Plywood | Applications with moderate exposure to moisture | Not fully waterproof, but can withstand moderate moisture |

| Marine Grade Plywood | Applications with constant exposure to water | Waterproof and suitable for submerged marine use |

| Structural Plywood | Structural applications | Not specifically designed for water resistance |

| Interior Grade Plywood | Indoor applications | Not designed for moisture resistance |

Key Takeaways: Is Exposure 1 Plywood?

- Exposure 1 plywood is a commonly used type of plywood in construction.

- It is designed to withstand temporary exposure to moisture during construction.

- Exposure 1 plywood is not suitable for prolonged exposure to water or outdoor use without proper protection.

- It is typically recommended for applications such as sheathing, subflooring, and roof decking.

- When using exposure 1 plywood, it is important to follow manufacturer’s guidelines and install with appropriate fasteners.

Frequently Asked Questions

Welcome to our FAQ section all about exposure 1 plywood! Have questions about this topic? We’ve got answers. Read on to learn more.

Is exposure 1 plywood suitable for outdoor use?

Yes, exposure 1 plywood is designed for exterior applications. It is made with a water-resistant glue that helps protect it from the elements. Whether you’re building a deck, shed, or other outdoor structure, exposure 1 plywood is a reliable choice. However, it’s important to note that prolonged exposure to moisture can still cause damage over time, so proper maintenance and sealing are recommended.

Additionally, it’s worth mentioning that exposure 1 plywood may not be suitable for applications where it will be fully exposed to water, such as underwater construction or in direct contact with the ground. In those cases, it’s best to consult with a professional for guidance on the appropriate type of plywood to use.

Can exposure 1 plywood be used for interior projects?

Yes, exposure 1 plywood can be used for interior projects as well. While it is designed primarily for exterior use, it can also be a suitable choice for certain interior applications. It is typically used in areas where moisture resistance is a consideration, such as bathrooms or kitchens where occasional splashes or high humidity levels may be present.

However, if you’re working on a project that requires a higher level of moisture resistance, such as a sauna or a steam room, it’s recommended to use a specific type of plywood designed for those conditions. Always check the manufacturer’s recommendations and consult with an expert if you’re unsure about the best plywood choice for your interior project.

What are the advantages of using exposure 1 plywood?

There are several advantages to using exposure 1 plywood. Firstly, it offers good strength and durability, making it suitable for a wide range of applications. It is also resistant to warping, shrinking, and cracking, which helps ensure its long-term stability.

Another advantage is its affordability. Exposure 1 plywood is generally more cost-effective compared to other specialty plywood options, making it a popular choice for budget-conscious projects. Additionally, its water-resistant properties make it versatile for both outdoor and certain interior uses.

How does exposure 1 plywood differ from other plywood types?

Exposure 1 plywood differs from other types of plywood primarily in terms of its intended use and level of water resistance. It is specifically manufactured for exterior applications, such as siding, soffits, and roofing, as well as for certain interior projects that require a higher level of moisture resistance.

Other types of plywood, such as CDX plywood, are also commonly used for exterior applications, but they may have different levels of water resistance and durability. Marine plywood, on the other hand, is specifically designed for underwater applications or those with constant exposure to moisture. It is important to choose the right type of plywood based on the specific requirements of your project.

Can exposure 1 plywood be stained or painted?

Yes, exposure 1 plywood can be stained or painted to achieve the desired appearance. However, it’s important to properly prepare the surface before applying any stains or paint. This typically involves sanding the plywood to create a smooth surface and removing any dust or debris.

It’s also recommended to use a primer before painting to ensure better adhesion and a more even finish. When staining, it’s important to test the stain on a small, inconspicuous area first to ensure that it achieves the desired color. Always follow the manufacturer’s instructions for the stain or paint you are using for best results.

Summary

Hey there! So, after reading the whole article, let me sum up what we’ve learned about exposure 1 plywood. Basically, exposure 1 plywood is a type of plywood that’s meant to be used in places where it might come into contact with moisture. It’s not waterproof, but it can handle a bit of dampness without getting damaged. That’s why it’s often used in construction for things like roof sheathing, walls, and subflooring. However, it’s important to remember that exposure 1 plywood should still be protected from long-term exposure to water to prevent any potential issues down the line.

So, to wrap it up, exposure 1 plywood is a useful material for certain construction projects where a little moisture resistance is needed. Just remember to use it in the right way and take measures to protect it from too much water.