When it comes to chisel handles, have you ever wondered what they’re made from? Well, get ready to dive into the world of woodworking, because we’re about to explore the materials used for chisel handles. From classic wooden handles to modern synthetic options, there’s a lot to discover! So, let’s get started and uncover the secrets behind these essential tools.

Chisel handles play a crucial role in the performance and comfort of a chisel, providing the user with a secure grip and control. Traditionally, chisel handles were crafted from hardwoods like beech, ash, or birch. These types of wood are known for their strength, durability, and resistance to wear and tear. Additionally, wooden handles offer a natural warmth and tactile feel, making them a popular choice among woodworkers.

However, as technology advances, so does the range of materials used for chisel handles. Nowadays, you can find synthetic materials like fiberglass-reinforced plastic or composite materials that offer increased durability and resistance to impacts and moisture. These modern handles are designed to withstand the demands of heavy use while providing ergonomic designs for enhanced comfort during long hours of work.

Whether you prefer the traditional charm of wooden handles or the modern practicality of synthetic options, chisel handles are an essential part of any woodworker’s toolkit. Now that we’ve delved into the materials used for chisel handles, it’s time to strap on your apron and pick up those chisels to embark on your next woodworking adventure!

What Are Chisel Handles Made From?

Chisel handles are an essential component of chisels, providing a comfortable grip and control while working on various projects. The material used for chisel handles plays a crucial role in the overall performance and durability of the tool. In this article, we will explore the different materials commonly used to make chisel handles and discuss their unique properties and benefits.

1) Wood

Wood is the traditional and most widely used material for chisel handles. It offers a natural and comfortable grip, allowing the user to have better control and precision. Various types of wood can be used, including beech, ash, and rosewood, each with its own distinct characteristics.

Beech wood is a popular choice due to its stability, durability, and resistance to wear and tear. It is also relatively lightweight, making it easier to handle during long hours of work. Ash wood, on the other hand, is known for its excellent shock-absorbing properties, making it ideal for heavy-duty applications. Rosewood is a more exotic option, prized for its aesthetic appeal, density, and ability to resist moisture.

2) Plastic

In recent years, plastic has gained popularity as an alternative material for chisel handles. Plastic handles are lightweight, durable, and resistant to impact and damage. They offer a comfortable grip and are suitable for both professional and DIY use.

Plastic handles also have the advantage of being more affordable compared to wooden handles. They are available in a range of colors and designs, allowing users to customize their tools according to their preferences. However, it is important to choose high-quality plastic handles that are resistant to wear and tear to ensure longevity.

3) Composite Materials

Composite materials, such as fiberglass and carbon fiber, are also used to make chisel handles. These materials offer excellent strength, rigidity, and resistance to impact, making them suitable for heavy-duty applications.

Fiberglass handles are lightweight, yet incredibly strong, making them ideal for chisels used in carpentry and woodworking. They are also resistant to moisture and have a high resistance to temperature changes, minimizing the risk of handle deformations. Carbon fiber handles, on the other hand, provide even greater strength and stiffness while maintaining a lightweight profile.

Composite material handles are often favored by professionals who require tools that can withstand extensive use and provide maximum control.

4) Metal

While less common than wood or plastic handles, metal handles offer unique benefits for certain applications. Metal handles are extremely durable and can withstand heavy use and abuse. They are often used in specialized chisels for stone carving or masonry work.

Metal handles can be made from steel or aluminum, with steel being the preferred option for its strength and resilience. However, metal handles can be less ergonomic and more prone to conducting heat or cold, making them less comfortable for extended periods of use.

5) Rubber

Rubber handles are commonly found in chisels used for masonry or tile work. Rubber offers excellent grip and shock absorption, allowing for improved control and reduced hand fatigue.

Rubber handles are also highly resistant to moisture and chemicals, making them suitable for use in wet or corrosive environments. They provide a secure grip even when the user’s hands are wet or oily, minimizing the risk of accidents.

6) Foam

Foam handles are lightweight and provide a soft, cushioned grip. They are often used in chisels that require repetitive or prolonged use, as they help reduce hand strain and fatigue.

Foam handles are also excellent at insulating against temperature extremes, providing a comfortable grip regardless of the weather conditions. They are commonly used in chisels for arts and crafts, as well as in some DIY applications.

7) Ergonomic Handles

Apart from the materials mentioned above, chisel handles can also feature ergonomic designs to improve user comfort and reduce strain. Ergonomic handles are shaped to fit the natural contours of the hand, allowing for a more relaxed grip and reducing the risk of injuries or repetitive strain.

Ergonomic handles can be made from various materials, including wood, plastic, or composite materials. The focus is on providing a comfortable grip and reducing hand fatigue during prolonged use.

Advancements in Chisel Handle Materials

In recent years, there have been significant advancements in chisel handle materials, with manufacturers continuously seeking to improve performance, durability, and user comfort. Some of the latest advancements include:

1) Anti-Vibration Handles

Anti-vibration handles use materials or designs that minimize the transmission of vibrations from the tool to the user’s hand. These handles are particularly beneficial for chisels used in heavy-duty applications or for extended periods of time. They help reduce hand fatigue and the risk of long-term injuries associated with prolonged exposure to vibrations.

2) Moisture-Resistant Handles

Moisture-resistant handles are designed to withstand exposure to high humidity or wet environments without deteriorating. These handles are often made from plastic, composite materials, or specially treated wood that is resistant to moisture and prevents rotting or warping.

Moisture-resistant handles are particularly useful in woodworking or construction applications where exposure to water or other liquids is common.

3) Shock-Absorbing Handles

Shock-absorbing handles are designed to reduce the impact felt by the user’s hand when striking or hitting a surface. These handles utilize materials or construction techniques that absorb and disperse the energy generated during use, minimizing strain on the hand and reducing the risk of injuries.

These handles are particularly beneficial for chisels used in heavy-duty applications or when working on hard materials such as stone or metal.

Conclusion

Chisel handles are made from various materials, each offering unique properties and benefits. Wood is the most common and traditional option, known for its natural grip and aesthetic appeal. Plastic, composite materials, metal, rubber, and foam are also used, each with its own advantages in terms of durability, comfort, and resistance to impact or moisture.

Advancements in chisel handle materials have led to the development of anti-vibration handles, moisture-resistant handles, and shock-absorbing handles, further enhancing user comfort and reducing the risk of injuries. When choosing a chisel, consider the type of work you will be doing and the specific demands of the task to select the most suitable handle material for your needs. Remember to prioritize comfort, grip, and durability to ensure a productive and enjoyable chiseling experience.

Key Takeaways: What Are Chisel Handles Made From?

Chisel handles are usually made from wood, such as beech or ash, as these types of wood are strong and durable.

Some chisel handles are also made from synthetic materials like fiberglass or plastic, which provide additional strength and resistance to wear and tear.

The choice of material for chisel handles depends on personal preference and intended use, as different materials offer different qualities.

Wooden chisel handles provide a traditional feel and are comfortable to grip, while synthetic handles may be more ergonomic and resistant to moisture.

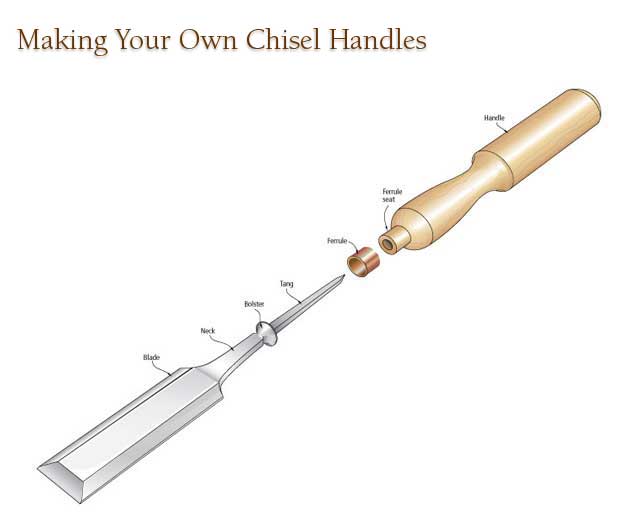

Regardless of the material, chisel handles should be securely attached to the blade to ensure safe and effective use.

Frequently Asked Questions

Curious about what materials chisel handles are made from? Look no further! Below you’ll find answers to some commonly asked questions about chisel handle materials.

1. What are some common materials used to make chisel handles?

Chisel handles can be made from a variety of materials, but some common ones include wood, plastic, and metal. Wood handles are traditional and provide a comfortable grip. They can be made from hardwoods like beech, ash, or hickory. Plastic handles are lightweight, durable, and often come in vibrant colors. Metal handles, like those made from steel or aluminum, are known for their strength and longevity.

While these materials are commonly used, there are also more unique options available. Some chisel handles are made from composite materials like fiberglass or carbon fiber, which offer a balance of strength and weight. Ultimately, the choice of material depends on factors like personal preference, intended use, and budget.

2. Are wooden chisel handles better than plastic or metal ones?

Whether wooden chisel handles are better than plastic or metal ones depends on various factors and personal preference. Wooden handles have been used for centuries and are cherished for their natural feel, excellent grip, and ability to dampen vibrations. They are also easy to shape and customize. However, wooden handles may require more maintenance, as they can be susceptible to moisture and may need occasional sanding or refinishing. They can also be more prone to breaking if subjected to excessive force.

On the other hand, plastic and metal handles offer advantages like being lightweight, less prone to breaking, and resistant to moisture. They often require less maintenance and can withstand heavy use. Additionally, plastic handles can be molded into ergonomic shapes, offering enhanced comfort during prolonged use. Ultimately, it boils down to personal preference and the specific needs of the user.

3. Can chisel handles be made from recycled materials?

Yes, chisel handles can be made from recycled materials, contributing to sustainable practices. Some manufacturers produce chisel handles from recycled plastics, reducing the waste generated from single-use plastics. These recycled materials can offer similar durability and performance as their non-recycled counterparts. Using recycled materials not only reduces environmental impact but also promotes resource conservation.

Furthermore, chisel handles made from salvaged or repurposed wood are another form of recycling. By using reclaimed wood from old furniture or structures, craftsmen can create unique and eco-friendly chisel handles. These handles preserve the beauty and history of the wood while reducing the need for new timber. So, yes, chisel handles can indeed be made from recycled materials.

4. Are there any benefits to using composite chisel handles?

Composite chisel handles, which are made from materials like fiberglass or carbon fiber, offer a range of benefits. One significant advantage is their strength-to-weight ratio. Composite materials can be incredibly strong while remaining lightweight, reducing operator fatigue during extended use. Additionally, composites are often resistant to moisture, chemicals, and temperature fluctuations, making them highly durable.

Another benefit of composite chisel handles is their ability to dampen vibrations. Compared to traditional wooden handles, composites can absorb and minimize shock, resulting in reduced hand fatigue and increased comfort. Moreover, composite materials can be molded into ergonomic shapes, providing a comfortable and precise grip, further enhancing usability. Overall, composite chisel handles can be an excellent choice for those seeking a balance of strength, durability, and ergonomic design.

5. Can I make my own custom chisel handle at home?

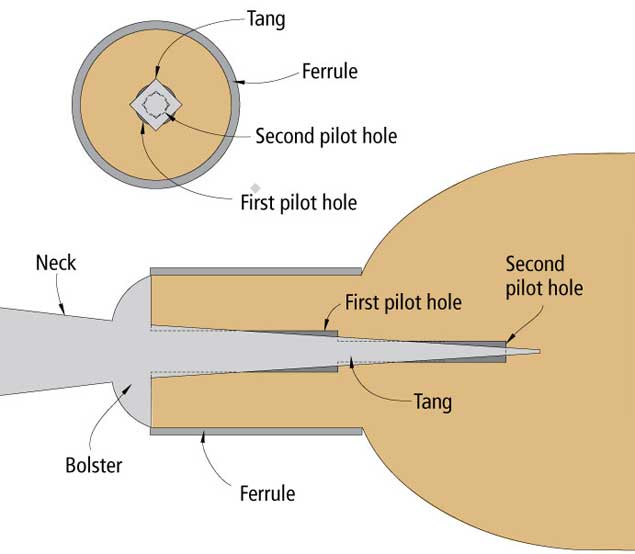

Yes, it is possible to make a custom chisel handle at home if you have the necessary tools and skills. Woodworking enthusiasts often enjoy crafting their own chisel handles from scratch. To make a wooden handle, you’ll need a piece of hardwood, such as beech, ash, or hickory, as well as woodworking tools like chisels, saws, and clamps.

There are numerous online resources, tutorials, and books available that guide you through the process of shaping, sanding, and finishing your custom chisel handle. It can be a rewarding project that allows you to create a handle tailored to your preferences and needs. However, keep in mind that making a chisel handle from scratch requires some woodworking skills and safety precautions, so it’s important to familiarize yourself with proper techniques before embarking on this DIY endeavor.

Why you should get chisels WITHOUT HANDLES!

Summary

Chisel handles are usually made from wood, specifically from durable types like beech and ash. The wood is shaped and carved into a comfortable grip for the user.

Sometimes, chisel handles can also be made from synthetic materials like plastic or rubber, which offer a different feel and grip. These handles are designed to be strong and sturdy, so they can withstand the pressure and force applied during chiseling tasks. Ultimately, the choice of material for chisel handles depends on factors like comfort, durability, and personal preference.