Hey there! If you’re just getting started with woodworking, you might be wondering, “What clamps do I need for woodworking?” Well, you’ve come to the right place! Clamps are essential tools for any woodworker, and they come in all shapes and sizes. So, let’s dive in and explore the clamps that will help you tackle your woodworking projects with ease.

When it comes to woodworking, having the right clamps can make all the difference. Clamps are like extra hands that hold your workpieces together while the glue dries or you’re making precise cuts. They ensure everything stays in place, resulting in accurate and professional-looking projects.

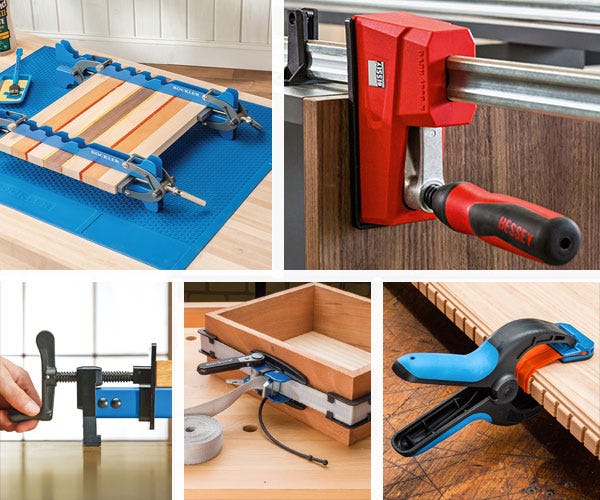

Whether you’re working on small craft projects or larger furniture pieces, there are a few types of clamps you’ll want to have in your toolbox. From bar clamps to spring clamps and everything in between, we’ll break down what each clamp does and which ones you should consider adding to your collection. So, let’s get ready to clamp down and unleash your woodworking potential!

If you’re into woodworking, having a variety of clamps is essential. Here are a few types of clamps you’ll need:

- C-clamps: These versatile clamps are great for holding objects together.

- Bar clamps: Perfect for larger projects, bar clamps offer a wide grip range.

- Spring clamps: These compact clamps are quick and easy to use for light-duty tasks.

- Pipe clamps: Ideal for gluing larger panels and tabletops.

- Parallel clamps: Known for their excellent clamping pressure and stability.

Having a combination of these clamps will ensure you have the right tool for any woodworking project!

What Clamps Do I Need for Woodworking? A Comprehensive Guide

Woodworking projects often require the use of clamps to hold pieces together securely while glue dries or to provide stabilization during various processes. With a wide range of clamps available, it can be overwhelming to determine which ones are essential for your woodworking needs. In this article, we will provide a comprehensive guide to help you understand what clamps you need for woodworking and how to choose the right ones for your projects.

1. C-Clamps

C-clamps are one of the most versatile clamps in woodworking, and every woodworker should have a few of these in their toolbox. They are named after their C-shaped design, which allows them to grip materials from the top and bottom. C-clamps are commonly used for securing small to medium-sized pieces during glue-ups or holding jigs and fixtures in place. These clamps come in various sizes and are available with different throat depths to accommodate different workpieces.

When selecting C-clamps, ensure that the throat depth is sufficient for the materials you will be working with. The throat depth is the distance from the top of the clamp’s opening to the surface where it contacts the workpiece. Additionally, opt for clamps with a sturdy construction and a comfortable handle for ease of use.

2. Bar Clamps

Bar clamps, also known as F-style clamps, are another essential type of clamp for woodworking. They consist of a sliding head that moves along a bar, allowing for adjustable clamping lengths. Bar clamps are commonly used for larger glue-ups, such as tabletops or cabinetry, as they provide a strong and even clamping force. These clamps come in various lengths, with longer ones offering greater reach and clamping capacity.

When choosing bar clamps, consider the length and clamping capacity that best suits your projects. Look for clamps with a quick-release mechanism or a quick-adjust feature to make adjustments easier and faster. Additionally, check for a smooth sliding action and a sturdy construction to ensure the longevity of your clamps.

3. Pipe Clamps

Pipe clamps are a versatile option for woodworking projects that require longer clamping lengths. As the name suggests, these clamps utilize pipes as the main component. The pipe acts as the bar, and the clamping heads are attached to either end. Pipe clamps are commonly used for gluing up wide panels, such as tabletops or large cabinet doors. The length of the pipe can be adjusted to accommodate different clamping lengths, making them highly adaptable.

When purchasing pipe clamps, opt for ones with a durable pipe that is resistant to bending or warping. Consider the size and weight of the pipe, as heavier pipes provide more stability and less potential for flexing. Additionally, choose clamps with secure and easy-to-use clamping heads that grip the pipe firmly.

4. Spring Clamps

Spring clamps, also known as hand clamps or pinch clamps, are small and lightweight clamps that are useful for a variety of woodworking tasks. They are designed with a spring-loaded mechanism that applies pressure when squeezed, allowing for quick and temporary clamping. Spring clamps are often used for securing small parts or holding objects in place during intricate woodworking processes, such as carving or sanding.

When selecting spring clamps, look for ones with a strong and durable spring that provides enough clamping force. Consider the size of the clamps, as larger ones offer a wider jaw opening and greater gripping capacity. Additionally, check for a comfortable handle grip, as these clamps are often held for extended periods.

5. Parallel Jaw Clamps

Parallel jaw clamps, also known as cabinet clamps or panel clamps, are specifically designed for flat panel glue-ups. They feature jaws that remain parallel throughout the clamping process, ensuring even pressure distribution across the workpiece. Parallel jaw clamps are ideal for large-scale projects, such as assembling cabinets or laminating tabletops, where precise alignment and a strong clamping force are crucial.

When choosing parallel jaw clamps, consider the jaw width and maximum opening capacity to ensure they can accommodate your workpieces. Opt for clamps with a quick-release mechanism or a trigger-operated system for easy and efficient clamping. Additionally, look for clamps with non-marring jaw pads to protect the surface of your workpiece.

6. Band Clamps

Band clamps, also known as strap clamps, are a versatile type of clamp that uses a band or strap instead of a solid bar. They are particularly useful for clamping irregularly shaped objects or large cylindrical objects, such as round tabletops or barrels. Band clamps are adjustable and can be tightened to fit various diameters or shapes, providing a secure hold during glue-ups or repairs.

When purchasing band clamps, look for ones with a sturdy and flexible band that can withstand tension without stretching or distorting. Consider the length and width of the band to ensure it can accommodate the size and shape of your workpieces. Additionally, opt for clamps with a reliable locking mechanism to hold the band securely in place.

7. Corner Clamps

Corner clamps, as the name suggests, are designed to hold pieces at a 90-degree angle, making them indispensable for assembling boxes, frames, or any project requiring precise right angles. These clamps typically feature adjustable jaws that can be tightened to secure the workpieces securely in place. Corner clamps ensure accurate and square glue-ups, minimizing the risk of misalignment or gaps.

When selecting corner clamps, ensure that the jaw size and clamping capacity are suitable for the dimensions of your project. Look for clamps with a sturdy construction and a reliable locking mechanism to maintain a consistent 90-degree angle. Additionally, consider the ease of adjusting the jaws to ensure efficient and hassle-free clamping.

Choosing the Right Clamps for Your Woodworking Projects

Woodworking projects come in various sizes and complexities, so it’s essential to have a collection of clamps that can accommodate different requirements. When building your clamp collection, consider the specific types of projects you frequently work on and the sizes and materials of the workpieces. Investing in quality clamps can make a significant difference in the quality and efficiency of your woodworking projects.

Additional Considerations

In addition to the types of clamps mentioned above, there are other clamps that may be beneficial for specific woodworking tasks. These include edge clamps, miter clamps, strap clamps, and specialty clamps such as veneer clamps or pinner clamps. Assess your woodworking needs and research the various types of clamps available to determine if any of these specialized clamps would be beneficial for your specific projects.

Remember that proper clamping is essential for successful woodworking. Ensure that your clamps are clean and free from any debris that could mar the surface of your workpieces. Regularly inspect your clamps for any signs of wear or damage and replace them as necessary. With the right clamps and proper technique, you can elevate your woodworking projects to the next level.

Key Takeaways: What Clamps Do I Need for Woodworking?

- Clamps are essential tools for woodworking projects.

- Bar clamps are versatile and can be used for different project sizes.

- Quick-grip clamps are great for smaller projects and tight spaces.

- Pipe clamps are ideal for longer projects such as tabletops or cabinets.

- C-clamps are useful for holding pieces together during assembly.

Frequently Asked Questions

When it comes to woodworking, clamps are essential tools that can make your projects easier and more efficient. Here are some common questions about what clamps you need for woodworking.

1. How do I choose the right clamps for woodworking?

Choosing the right clamps for woodworking depends on the specific project you’re working on. There are different types of clamps available, such as bar clamps, C-clamps, pipe clamps, and parallel clamps, each with their own functions and advantages. Consider factors like the size and thickness of the wood, the pressure required, and the overall stability needed for your project. Research different clamp types and their recommended uses to determine the best options for your woodworking needs.

Additionally, it’s helpful to have a variety of clamp sizes in your toolbox. Small clamps are ideal for delicate work or securing smaller pieces, while larger clamps are useful for larger-scale projects. It’s also a good idea to invest in high-quality clamps, as they can provide better stability and ensure your woodworking projects turn out well.

2. Can I use any type of clamp for woodworking?

While there are different types of clamps available, not all of them are suitable for woodworking purposes. It’s essential to choose clamps specifically designed for woodworking to ensure they can withstand the pressure and stress of various woodworking techniques.

Woodworking clamps are typically designed to provide even pressure along the surface of the wood, preventing warping or damage. They often have features like padded jaws or soft surfaces to protect the wood from getting marked or dented. These clamps are built to hold the pieces securely in place while the glue dries or during other woodworking processes. Using non-woodworking clamps may not provide the necessary stability or protection, compromising the quality of your projects.

3. How many clamps do I need for woodworking?

The number of clamps you need for woodworking depends on the size and complexity of your projects. It’s generally recommended to have a variety of clamps on hand to accommodate different woodworking needs. As a basic guideline, having at least 4-6 clamps of various sizes is a good starting point for most beginners.

Keep in mind that you may need more clamps for larger projects or when working with multiple pieces at once. Additionally, it’s helpful to have different types of clamps for specific tasks. For example, bar clamps are great for large panels, while spring clamps are handy for holding smaller pieces in place temporarily. As you gain more experience in woodworking, you’ll develop a better understanding of how many clamps you typically need for different projects.

4. What are the advantages of different clamp types for woodworking?

Each type of clamp has its own advantages and recommended uses in woodworking. For example, bar clamps are versatile and suitable for a wide range of woodworking tasks, while C-clamps are often used for smaller projects or holding pieces temporarily. Pipe clamps offer long reach capabilities and are great for larger glue-ups, while parallel clamps provide even pressure across wider surfaces.

By understanding the unique advantages of different clamps, you can choose the most suitable type for your specific woodworking needs. Experimenting with various clamp types and understanding their features will allow you to make more informed decisions when selecting the right tools for your projects.

5. Any tips for using clamps effectively in woodworking?

Using clamps effectively in woodworking requires proper technique and attention to detail. Here are a few tips to help you maximize their effectiveness:

Avoid over-tightening: While clamps are meant to provide pressure, excessive force can cause damage to the wood. Apply enough pressure to hold the pieces securely without crushing or distorting them.

Use scrap blocks: To prevent clamps from marking the wood surface, use scrap blocks or protective pads between the clamps and the wood. This helps distribute pressure evenly and protects the wood from damage.

Plan ahead: Understand your project requirements and plan where you’ll need clamps before starting the woodworking process. This will help you determine the best placement and number of clamps to use, ensuring a smooth workflow.

Regularly check and adjust: As glue dries and wood settles, it’s important to regularly check your clamps and make necessary adjustments. This will maintain proper pressure throughout the project and ensure the best results.

By following these tips, you’ll be able to use clamps effectively and enhance the quality of your woodworking projects.

How many clamps do you REALLY need? Woodworking basics.

Summary

If you’re into woodworking, you’ll need clamps to hold your projects together. Clamps come in different types and sizes, such as C-clamps, bar clamps, and pipe clamps. The type and size you need depend on the project you’re working on, so it’s important to choose the right ones. Consider factors like the size of your workpiece, the pressure you need, and the type of joint you’re making. Remember to have a few different clamps in your collection to handle various woodworking tasks.

In addition to the clamps themselves, there are some accessories worth considering. For example, clamp pads can protect your workpiece from getting damaged by the clamp’s pressure. Another useful accessory is a clamp extender, which allows you to use multiple clamps together for larger projects. Finally, it’s always helpful to have a good supply of small clamps for delicate or intricate work. Don’t forget to take care of your clamps by cleaning and storing them properly to ensure they last longer. So, get the right clamps and accessories, and start creating amazing woodworking projects!