If you’re curious about carpentry and want to know more about it, you may have come across the term “header.” But what exactly is a header in carpentry? Let’s dive in and find out!

In the world of carpentry, a header is a vital component that provides structural support. Think of it as the backbone of a door or window frame, ensuring stability and strength. But that’s not all – headers also help distribute the weight of the structure evenly, preventing sagging or collapsing.

Headers are typically made from sturdy materials like wood or steel, depending on the specific requirements of the project. They are strategically placed above openings such as doors, windows, or large openings in walls to bear the load exerted by the structure above.

So, the next time you admire a beautifully crafted door or window, remember that behind its elegance lies a humble header, ensuring stability and strength. Now that you know the importance of headers in carpentry, let’s explore their different types and functions in more detail.

What is a Header in Carpentry?

1)

Definition of a Header in Carpentry

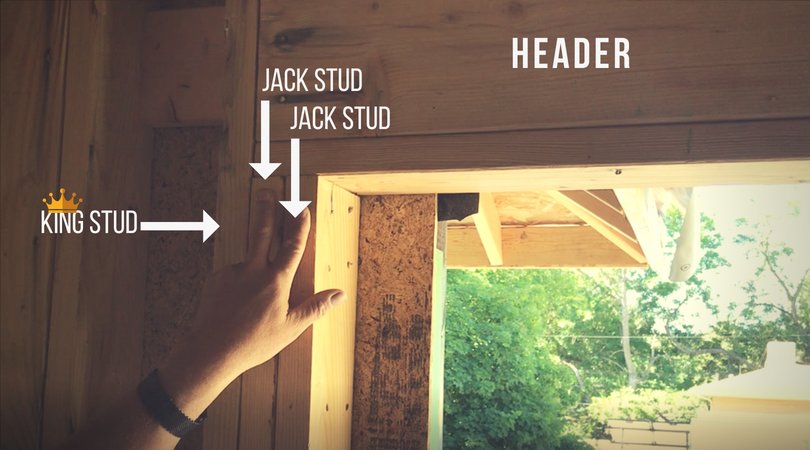

A header in carpentry refers to a structural component that spans a distance between two vertical supports, such as walls or columns. It is typically made of wood or engineered wood products like laminated veneer lumber (LVL) or glue-laminated timber (glulam). Headers are essential for transferring the weight of the structure above, ensuring proper load distribution, and providing stability and support. The size and material of the header will vary depending on the specific application and load requirements.

Headers are commonly used in framing doors, windows, and openings in walls. They bear the weight of the structure above, distributing it evenly to the vertical supports on either side of the opening. By carrying this load, headers prevent sagging and ensure the structural integrity and longevity of the building. They also allow for larger openings, such as wide windows or grand entranceways, by providing the necessary support to compensate for the removed material.

2)

Types of Headers in Carpentry

There are different types of headers used in carpentry, each suited for specific applications and load requirements. The three main types are solid sawn headers, engineered wood headers, and steel headers.

Solid sawn headers are made from a single piece of lumber, usually dimensional lumber like 2×6 or 2×8. They are the most common type of header and are suitable for light to moderate loads. However, they have limitations in terms of maximum spans and may require additional support or reinforcement for larger openings.

Engineered wood headers, such as LVL or glulam, offer greater strength and load-carrying capacity compared to solid sawn headers. They are made by bonding multiple layers of wood together, resulting in a more uniform and structurally sound product. Engineered wood headers can span longer distances and are often used for larger openings or when higher loads need to be supported.

Steel headers offer exceptional strength and durability. They are typically used in commercial or industrial applications where heavy loads or long spans are common. Steel headers are engineered to meet specific load requirements and offer the advantage of being non-combustible and resistant to rot, pests, and moisture.

3)

Installation of Headers in Carpentry

Proper installation of headers is crucial to ensure the structural integrity of a building and prevent issues like sagging or uneven loading. The process of installing a header involves accurately measuring the opening, selecting the appropriate header material and size, and securely fastening it in place.

Before installation, it is important to check local building codes and regulations to ensure compliance with load-bearing requirements and other relevant factors. The size and span of the opening will determine the dimensions of the header needed. It is recommended to consult a structural engineer or an experienced carpenter to determine the specific requirements for your project.

Once the header dimensions are established, the next step is to remove any existing framing from the opening and prepare the area for installation. This may involve removing drywall or other finishes, as well as temporary bracing to support the structure during the installation process.

The header is then placed into position and secured to the surrounding framing using appropriate fasteners, such as nails, screws, or structural connectors. It is crucial to ensure that the header is level, plumb, and properly aligned with the opening to facilitate proper load transfer and prevent any structural issues.

In some cases, additional supports or trimmers may be required to further reinforce the header and distribute the load. These supports are typically installed on either side of the opening, providing additional stability and preventing any sagging or movement of the header.

Overall, proper installation of headers in carpentry is a critical step in the construction or renovation process. It requires careful planning, accurate measurements, and adherence to structural engineering principles to ensure a safe and structurally sound building.

Key Takeaways: What is a Header in Carpentry?

- A header in carpentry is a horizontal beam that provides structural support above an opening.

- Headers are commonly used in doorways and windows to distribute the weight of the structure above.

- They are typically made from wooden boards or steel beams, depending on the size and load requirements.

- Headers play a crucial role in maintaining the integrity and stability of the overall structure.

- Proper installation and sizing of headers are essential to ensure the safety and durability of the carpentry project.

Frequently Asked Questions

Welcome to our FAQ section where we answer your questions about headers in carpentry. Whether you’re a beginner or a seasoned carpenter, understanding headers is crucial for successful construction projects. Read on to find answers to commonly asked questions.

1. What is the purpose of a header in carpentry?

A header in carpentry refers to a structural element used to support the weight of a load-bearing wall or opening in a building. It distributes the weight evenly across the span, ensuring stability and preventing sagging. Headers are commonly used above windows, doors, and other large openings.

By providing additional support, headers help transfer the load from above down to the foundation or adjacent walls, reducing the risk of structural damage. This is especially important in cases where the wall or opening bears heavy loads, such as in multi-story buildings or spaces with large windows.

2. What materials are used to make headers in carpentry?

Headers in carpentry can be made from various materials, depending on the specific requirements and building codes. The most common materials used are wood and engineered wood products like laminated veneer lumber (LVL) or plywood. These materials offer high strength and reliability while allowing for flexibility in design.

Additionally, steel beams can also be used as headers, especially in commercial or industrial construction where longer spans and higher loads are common. The choice of material for a header depends on factors such as the load it needs to support, budget constraints, and local building regulations.

3. How do you determine the size of a header in carpentry?

The size of a header in carpentry depends on several factors, including the span it needs to cover, the load it needs to support, and the material used. Building codes provide guidelines for determining the appropriate header size based on these factors.

A structural engineer or an experienced carpenter can accurately calculate the required header size by considering the dimensions of the opening, the types of loads it will bear, and the local building code requirements. It is crucial to ensure proper sizing to maintain the structural integrity of the building and avoid any potential hazards.

4. Are there different types of headers in carpentry?

Yes, there are different types of headers in carpentry based on their construction and application. Common types include solid sawn headers, engineered wood headers, and steel headers.

Solid sawn headers are made by cutting and joining lumber boards together. Engineered wood headers, such as LVL or laminated strand lumber (LSL), are manufactured by bonding wood veneers or strands together to create a stronger and more reliable material. Steel headers are made from steel beams that provide exceptional strength and resistance to bending.

5. Can I install a header myself, or do I need professional help?

Installing a header in carpentry requires a good understanding of structural principles and construction techniques. While some experienced DIYers might be able to handle the task, it is generally recommended to seek professional help, especially for load-bearing walls or larger openings.

A professional carpenter or contractor has the necessary expertise to determine the appropriate header size, select the right materials, and ensure proper installation according to local building codes. This helps ensure the structural integrity of the building and reduces the risk of potential safety hazards that may arise from improper installation.

Summary

A header in carpentry is a horizontal beam used to support the weight of a structure. It is placed above doors and windows and helps to distribute the weight evenly. Headers are important because they prevent sagging and ensure that the structure remains stable.

Headers can be made from various materials, including wood and metal. The choice of material depends on factors such as the load-bearing requirements and the structural design. It is crucial to follow building codes and consult with professionals to ensure the correct size and material for headers in carpentry projects.