Have you ever wondered, “What is a radial drill press?” Well, you’re in luck because I’m here to give you the lowdown! A radial drill press is a versatile tool that can make drilling holes a breeze.

So, what sets a radial drill press apart from other drills? The key feature of a radial drill press is its ability to move its spindle horizontally and vertically. That means you can position the drill bit exactly where you need it, no matter the size or shape of the workpiece.

Whether you’re a woodworking enthusiast or a DIY pro, a radial drill press is a must-have in your toolkit. It offers precision, control, and convenience, making it easier than ever to tackle your drilling projects with confidence. So, let’s dive in and explore the world of radial drill presses together!

What is a Radial Drill Press? An Essential Guide

A radial drill press is a versatile machine tool used in woodworking and metalworking industries. Its unique design allows the drill head to be positioned over a large worktable, allowing for precise drilling and machining operations. In this comprehensive guide, we will explore the various features, applications, and benefits of a radial drill press. Whether you’re a professional machinist or an avid DIYer, this article will provide you with the knowledge you need to understand and leverage the power of a radial drill press.

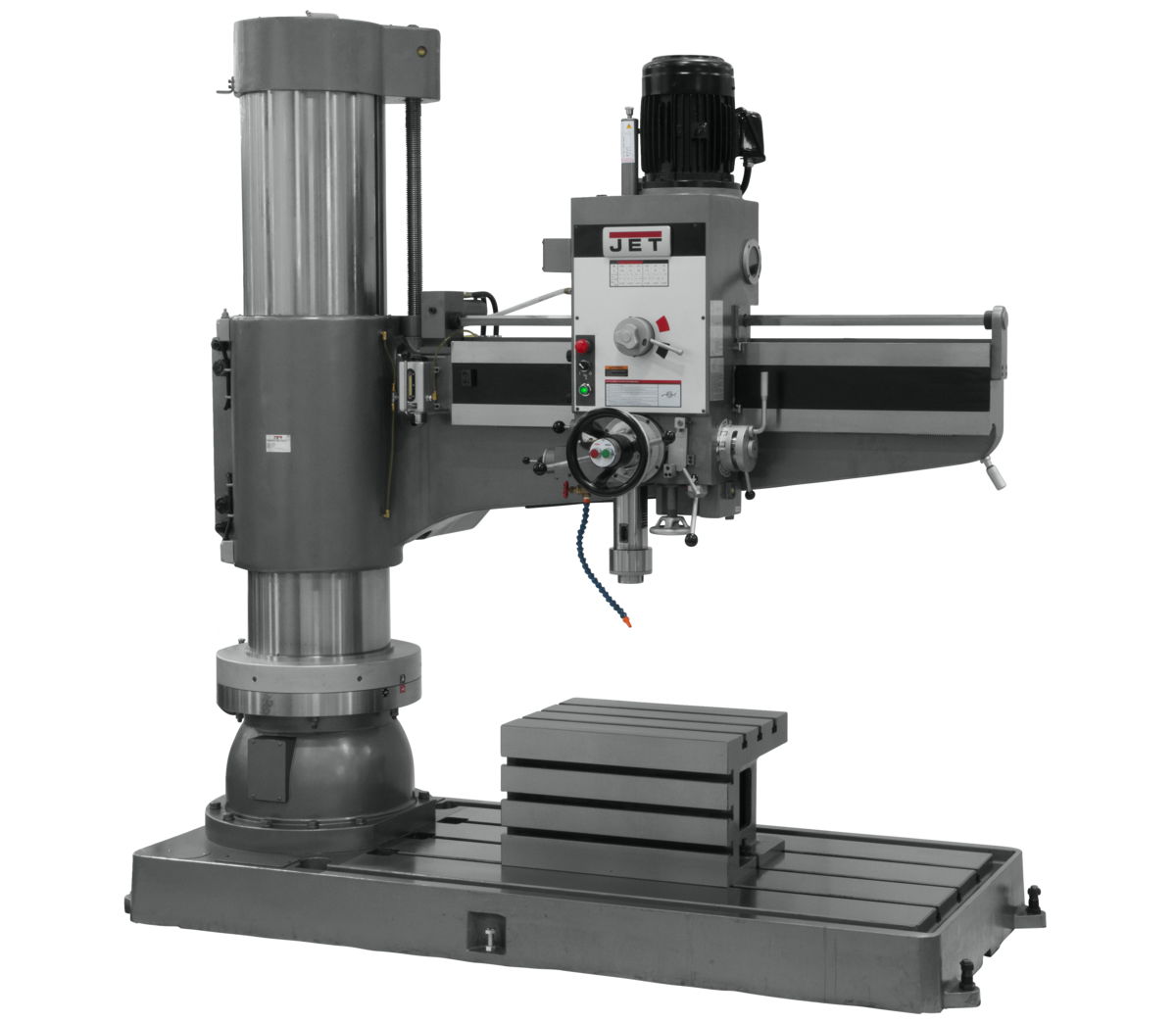

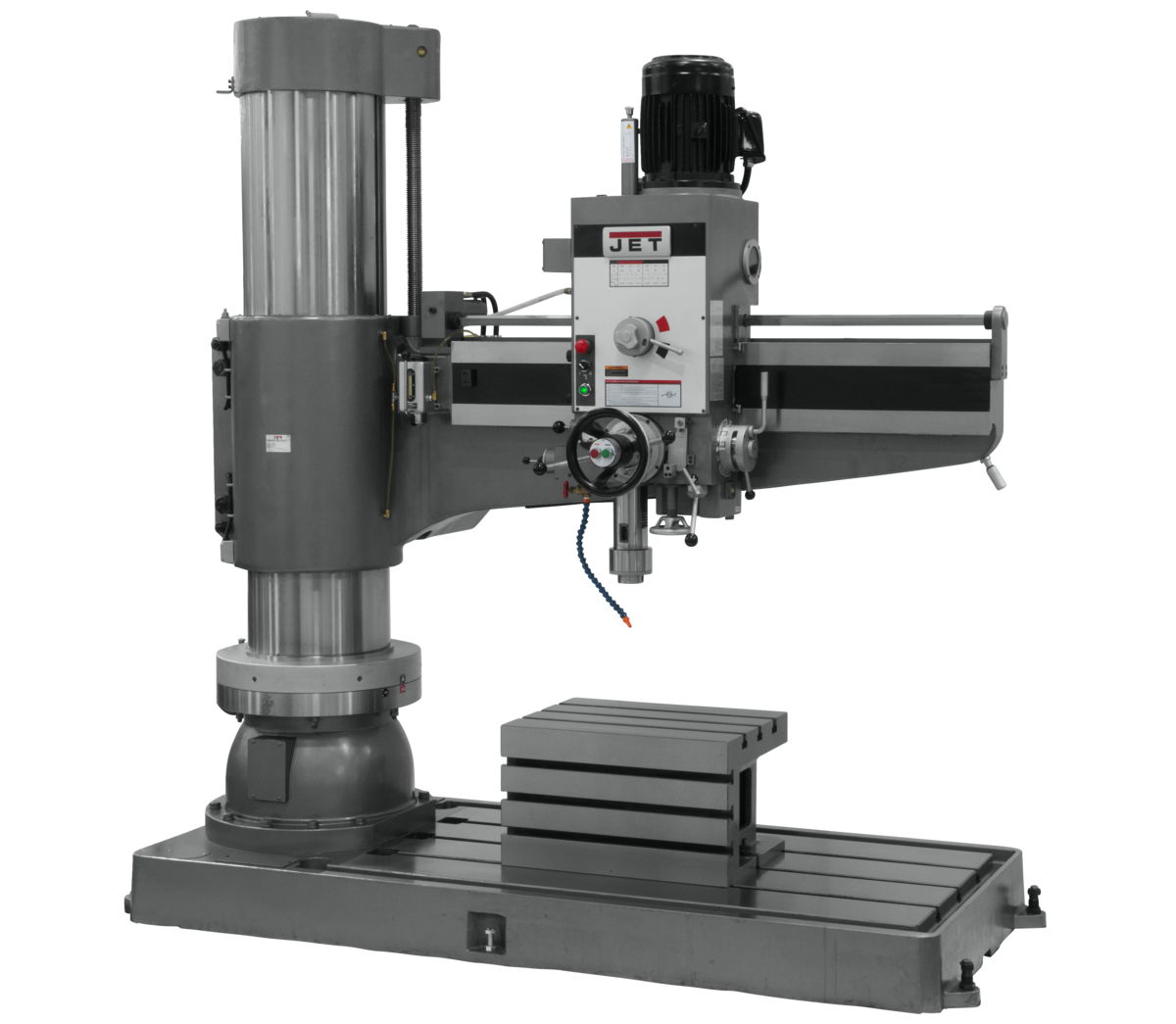

The Anatomy of a Radial Drill Press: Exploring the Components

Before delving into the applications and benefits of a radial drill press, it’s essential to understand its key components. A radial drill press consists of several parts that work together to provide accurate and efficient drilling capabilities. Let’s take a closer look at each component:

The Base:

The base is the foundation of the radial drill press and provides stability during operation. It is typically made of sturdy cast iron to ensure rigidity and minimize vibrations. The base also serves as a mount for other components, such as the column and the worktable.

The Column:

The column is a vertical support structure connected to the base. It houses the drive mechanism that raises and lowers the drill head. The column’s height can often be adjusted to accommodate different workpiece sizes.

The Worktable:

The worktable is a flat surface placed on top of the column. It provides support for the workpiece and can be tilted, rotated, or moved horizontally to facilitate precise drilling operations. The worktable also features slots or T-slots for securing clamps or other workholding devices.

The Drill Head:

The drill head is the crucial component that houses the drilling motor and the spindle. It can be moved along the arm, allowing for radial positioning over the worktable. The drill head also features a quill that holds the drill bit and can be raised or lowered using a handle or a control knob.

…

Applications of a Radial Drill Press: From Woodworking to Metalworking

A radial drill press finds applications in various industries, spanning from woodworking to metalworking. Here are some of the key applications where a radial drill press excels:

Woodworking:

In woodworking, a radial drill press is used to create precise holes for dowels, joinery, and hardware installation. It is also commonly used to drill holes for cable management in furniture and cabinetry. With its versatility and accuracy, a radial drill press is a valuable tool in any woodworking shop.

Metalworking:

In the metalworking industry, a radial drill press provides the ability to drill accurate holes, tap threads, and countersink holes in various metal materials. It is commonly used in the production of metal parts, such as gears, shafts, and brackets.

Automotive and Aerospace:

Radial drill presses are frequently used in the automotive and aerospace industries for a range of applications such as drilling holes in engine blocks, manufacturing aircraft components, or working on maintenance and repair tasks.

…

Benefits of Using a Radial Drill Press: Efficiency and Precision Combined

A radial drill press offers several significant benefits that make it an indispensable tool in many workshops. Let’s explore some of the key advantages:

Positioning Flexibility:

One of the primary advantages of a radial drill press is its ability to position the drill head radially. This feature allows users to drill holes at various angles and positions on the workpiece, making it ideal for complex drilling operations.

Enhanced Control and Accuracy:

The radial drill press provides excellent control and precision, thanks to its rigid construction and adjustable components. Users can easily adjust the drilling depth, speed, and feed rate to achieve accurate results, even when working with challenging materials.

Time and Cost Savings:

With its efficient operation and versatility, a radial drill press can significantly reduce the time and effort required for drilling operations. It eliminates the need for manual drilling, reducing human error and increasing productivity. Additionally, the ability to perform multiple operations on a single machine saves space and costs associated with using multiple tools.

…

Choosing the Right Radial Drill Press: Factors to Consider

When selecting a radial drill press, several factors should be taken into consideration to ensure you find the right machine for your needs:

Workshop Space and Workpiece Size:

Consider the available space in your workshop and the dimensions of the workpieces you typically work with. Radial drill presses come in various sizes, so choose one that fits well in your workspace and allows for easy maneuverability.

Power and Speed:

Different drilling tasks require different power and speed settings. Consider the materials you’ll be working with and choose a radial drill press with sufficient power and adjustable speed options to accommodate your needs.

Features and Accessories:

Look for additional features and accessories that can enhance the versatility and functionality of the radial drill press. Some common features include built-in work lights, digital depth indicators, and quick-release chucks.

…

Maintaining and Caring for Your Radial Drill Press

To ensure your radial drill press continues to perform optimally and safely, regular maintenance is essential. Here are some tips for maintaining and caring for your machine:

Clean Regularly:

Keep your radial drill press clean by regularly removing dust, debris, and excess oil or grease. Use a soft cloth or brush to wipe down the surfaces and components, and ensure all moving parts are well lubricated.

Inspect for Wear and Tear:

Periodically check for any signs of wear or damage, such as loose or worn-out belts, damaged wiring, or excessive vibration. Address any issues promptly to prevent further damage and ensure the safety of operation.

Follow Manufacturer’s Guidelines:

Refer to the user manual and follow the manufacturer’s guidelines for maintenance and operation. This will help maximize the lifespan of your radial drill press and ensure it operates at its best.

…

Wrap-Up:

A radial drill press is a versatile and essential tool for both woodworking and metalworking industries. Its unique design and capabilities make it suitable for a wide range of drilling and machining operations, offering efficiency, precision, and flexibility. By understanding its components, applications, and benefits, you can make an informed decision when choosing the right radial drill press for your needs. Remember to prioritize maintenance and care for your machine to ensure long-lasting performance. With a radial drill press in your workshop, you’ll be well-equipped to tackle a multitude of drilling tasks with ease and precision.

Key Takeaways: What is a Radial Drill Press?

- A radial drill press is a type of drilling machine that allows you to drill holes at different angles and positions.

- It has a movable radial arm that can be adjusted to reach the desired drilling area.

- Radial drill presses are commonly used in metalworking industries for drilling precision holes in various materials.

- These machines offer flexibility and accuracy, making them ideal for tasks that require precise hole drilling.

- Radial drill presses are equipped with a variety of attachments and accessories to enhance their functionality.

Frequently Asked Questions

In the world of machining and drilling, the radial drill press is a commonly used tool. It is designed to provide flexibility and precision in various drilling operations. Below, you will find answers to some common questions about radial drill presses.

1. How does a radial drill press differ from a regular drill press?

A radial drill press differentiates itself from a regular drill press in terms of its design and functionality. While a regular drill press has a fixed drill head placed on a vertical column, a radial drill press features a movable arm that can swing horizontally, vertically, or both. This arm, or radial arm, allows the drill to be positioned at different angles and distances from the workpiece, providing greater flexibility in drilling operations. This feature makes it suitable for drilling operations requiring a larger reach or drilling at unconventional angles.

Additionally, a radial drill press often has a larger work table and a more powerful motor compared to a regular drill press, enabling it to handle heavier workpieces and more demanding drilling tasks. Overall, the radial drill press offers enhanced versatility and maneuverability compared to its conventional counterpart.

2. What are the benefits of using a radial drill press?

The use of a radial drill press provides several advantages in drilling operations. First and foremost, its ability to move the drill head horizontally and vertically allows for greater flexibility in positioning the drill bit, making it easier to reach difficult spots on a workpiece. This versatility is especially beneficial when working with larger or oddly shaped objects.

Moreover, the radial arm of the drill press enables drilling at various angles, making it suitable for tasks that require angled holes or drilling into irregular surfaces. This eliminates the need for additional equipment or complex setups. Additionally, the larger work table of a radial drill press provides a stable and spacious platform to support the workpiece during drilling, ensuring accuracy and reducing the risk of errors.

3. What are the limitations of a radial drill press?

While a radial drill press offers many advantages, there are some limitations to consider. One limitation is that a radial drill press requires more space compared to a regular drill press due to its swinging arm. This can be a constraint in small workshops or areas with limited floor space.

Another limitation is that the moving arm introduces some complexity in terms of setup and adjustment. It may take some time and practice to become familiar with positioning the drill head accurately, especially when working with precise measurements. Lastly, the swinging arm can also introduce some potential for vibration or instability, which can affect drilling precision. However, with proper setup and operation, these limitations can be mitigated.

4. What types of materials and applications are suitable for a radial drill press?

A radial drill press is a versatile tool that can handle a wide range of materials and applications. It is suitable for drilling various metals, such as steel, aluminum, and cast iron, as well as wood and plastic. The flexibility in positioning the drill head makes it ideal for tasks that require drilling holes at different angles, depths, or distances from the edge of the workpiece.

Some common applications of a radial drill press include drilling holes for bolts, dowels, and fasteners, creating holes for pipe fittings, and performing precision drilling in metal fabrication, woodworking, and construction projects. Its ability to handle larger workpieces and perform angled drilling also makes it suitable for tasks like drilling holes in structural components or creating holes for wiring and cables.

5. How should I maintain and care for a radial drill press?

Proper maintenance and care are essential to ensure the longevity and optimal performance of a radial drill press. Regularly inspect the machine for any signs of wear, loose parts, or alignment issues. Keep the moving parts lubricated according to the manufacturer’s recommendations to reduce friction and prevent premature wear.

Additionally, keep the work table clean and free from debris to ensure smooth movement and accurate positioning. It is also important to regularly check and adjust the belt tension, if applicable, and inspect the drill bits for sharpness and integrity. If any issues or abnormalities arise, consult the manufacturer’s manual or seek professional assistance to address them promptly and prevent further damage.

Summary

A radial drill press is a useful tool that helps us make precise holes in different materials. It has a movable arm that can swing around, making it easier to drill in the right spot. This machine is commonly used in workshops and factories to create holes of various sizes and depths.

When using a radial drill press, it’s important to remember safety precautions like wearing protective gear and securing the workpiece properly. By adjusting the speed and depth of the drill, we can achieve accurate results. This versatile tool is essential for woodworking, metalworking, and many other projects that require precise drilling. So, if you’re ever in need of drilling holes, a radial drill press is your go-to tool!