Have you ever wondered why metal lathes are so widely used? Well, let me tell you! Metal lathes are nifty machines that have been around for centuries and continue to play a crucial role in various industries today. So, why are they so popular? Let’s dive in and find out!

Here’s the deal: Metal lathes are used for shaping and cutting metal into different shapes and sizes. They are like the superheroes of the manufacturing world, with the power to transform raw chunks of metal into beautifully crafted pieces. Whether it’s creating precise threads on bolts or turning cylindrical objects with precision, metal lathes are the go-to machines.

Now, you might be wondering, “Why not just use other tools?” Great question! Metal lathes offer unparalleled accuracy and versatility. They can create intricate designs, cylindrical shapes, and even tapered forms with ease. With the ability to remove material from the workpiece, metal lathes allow engineers and craftsmen to achieve precise measurements and achieve the desired finish.

So, whether you’re a seasoned professional or just starting your journey into the world of metalworking, understanding why metal lathes are used is essential. These powerful machines bring an array of benefits, from shaping metal with precision to creating beautifully crafted pieces. Ready to dive deeper? Let’s explore the fascinating world of metal lathes together!

Why is Metal Lathe Used?

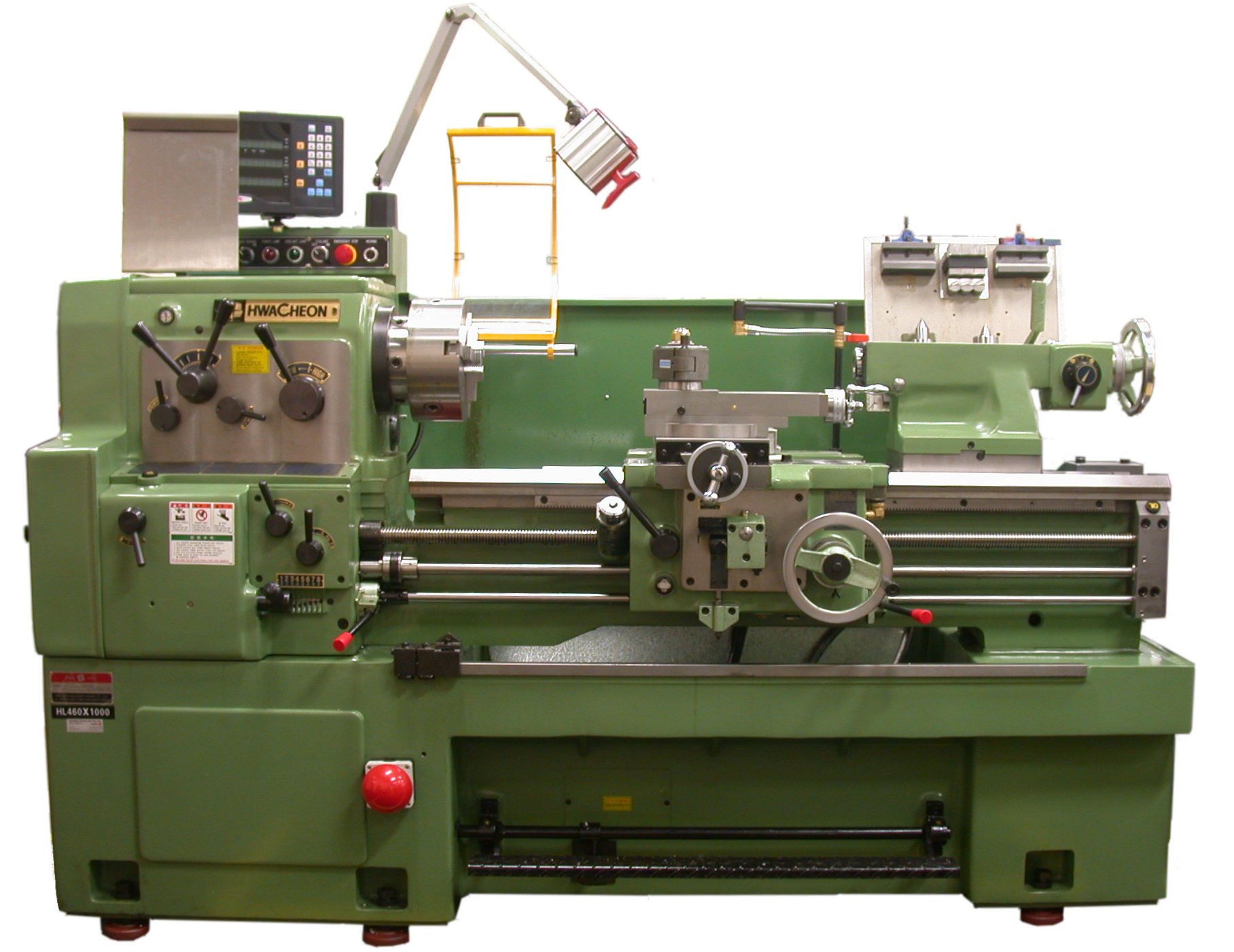

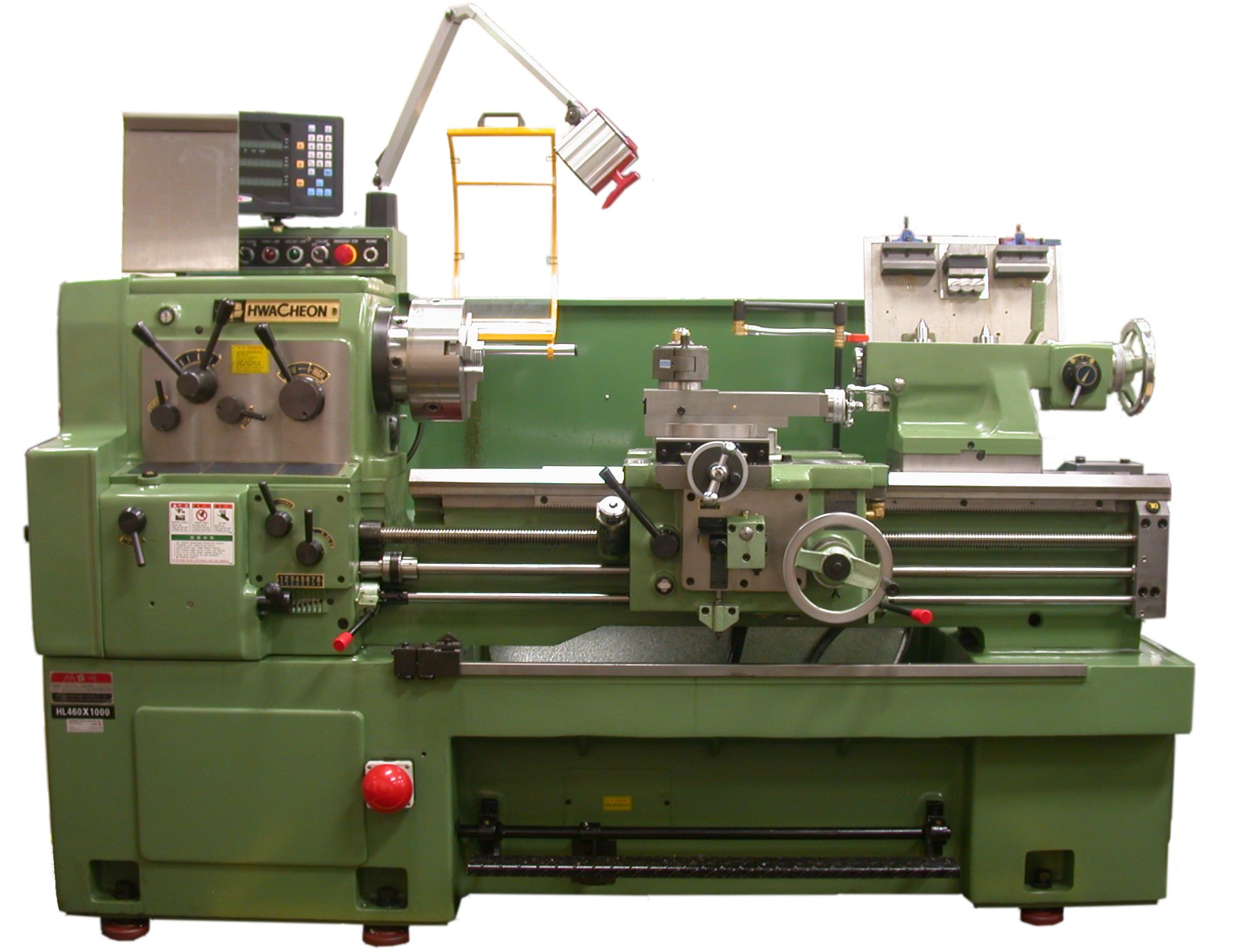

Metal lathe is a versatile tool widely used in manufacturing, machining, and woodworking industries. It plays a crucial role in shaping, cutting, and forming various metal and wood materials. The primary purpose of a metal lathe is to rotate a workpiece on an axis while a cutting tool shapes and forms the material. This process allows for precise and intricate shaping, making it an essential tool in many industries.

Whether it’s creating intricate details on jewelry or manufacturing intricate parts for machinery, metal lathes provide the precision and accuracy required. The ability to cut, drill, bore, and thread materials makes metal lathes an indispensable tool for engineers, craftsmen, and hobbyists alike. From shaping metal pipes to creating screws and bolts, metal lathes enable users to unleash their creativity and produce high-quality, custom-made products.

1. Industrial Applications of Metal Lathe

In the industrial sector, metal lathes are extensively used for mass production and fabricating various metal components. Industries such as automotive, aerospace, and construction rely heavily on metal lathes for manufacturing precision parts and components. With metal lathes, manufacturers can achieve consistent quality, accuracy, and precision, ensuring the functionality and durability of the final product. From engine shafts to gears and pistons, metal lathes play a vital role in creating these essential components.

Moreover, metal lathes are also used in the production of tools, dies, and molds. The ability to shape and form metal with precision allows manufacturers to create custom tools specific to their needs. This increases efficiency and reduces production time, making metal lathes a valuable asset in the industrial sector.

Besides, metal lathes find applications in the fabrication of musical instruments, such as brass instruments and percussion instruments. The ability to turn and shape metal with precision allows instrument makers to create intricate designs and achieve the desired sound quality.

2. Woodworking Applications of Metal Lathe

Metal lathes are not limited to metalworking; they also excel in the field of woodworking. Woodturning, the art of shaping wood on a lathe, has gained significant popularity in recent years. Woodworkers use metal lathes to create beautiful and intricate designs on wooden objects, such as bowls, spindles, vases, and furniture legs.

By fixing a wooden workpiece onto the lathe and rotating it, woodworkers can use various cutting tools to shape and form the wood. Metal lathes provide the speed, precision, and control required to create symmetrical and perfectly balanced wooden objects. Whether it’s creating a unique piece of furniture or crafting a decorative item, metal lathes offer woodworkers the versatility and freedom to explore their creativity.

Furthermore, metal lathes can be used for other woodworking applications, such as drilling holes, sanding, and carving. This makes them a valuable tool for both professional woodworkers and hobbyists alike.

3. Home DIY and Hobbyist Applications of Metal Lathe

Metal lathes are not limited to industrial and professional settings. They are also widely used by DIY enthusiasts and hobbyists. Having a metal lathe at home enables individuals to explore their interests in metalworking, woodworking, and various crafts.

For DIY enthusiasts, metal lathes offer the opportunity to create and repair various metal and wooden items. From crafting custom-made jewelry pieces to building small-scale models, metal lathes provide the precision and control required to bring ideas to life. There is a sense of satisfaction in being able to design and create unique pieces with your own hands.

Moreover, metal lathes can be a great learning tool for individuals interested in machining and engineering. By experimenting and practicing on a metal lathe, beginners can learn the fundamentals of metalworking and woodworking. The hands-on experience helps develop skills such as measuring, cutting, and shaping materials with precision, laying a solid foundation for further learning and growth.

H2 Heading 1: Metal Lathe vs. Other Machining Tools

When it comes to machining and shaping materials, there are various tools available in the market. Each tool has its own advantages and limitations. Let’s explore how a metal lathe compares to other machining tools:

1. Metal Lathe vs. Milling Machine

A milling machine is another widely used tool in the machining industry. While both milling machines and metal lathes can shape and form materials, they differ in their operations and capabilities.

A metal lathe rotates the workpiece on its axis while a cutting tool shapes the material. On the other hand, a milling machine uses rotating cutters to remove material from the workpiece, creating complex shapes and patterns. Metal lathes are typically used for cylindrical and symmetrical objects, while milling machines excel at creating intricate designs and flat surfaces.

Overall, both tools complement each other and are often used together in metalworking and machining applications to achieve desired results.

2. Metal Lathe vs. CNC Machine

CNC (Computer Numerical Control) machines have revolutionized the machining industry, offering high precision and automation. While CNC machines can perform various tasks, including lathe operations, they differ from traditional metal lathes.

A CNC lathe operates based on programmed instructions, using computer precision to rotate the workpiece and shape it with the cutting tool. Traditional metal lathes, on the other hand, require manual operation and control from the user.

While CNC machines offer enhanced accuracy, efficiency, and automation, traditional metal lathes offer greater versatility and flexibility in shaping and forming materials. Additionally, traditional metal lathes are more accessible and affordable for DIY enthusiasts and hobbyists.

H2 Heading 2: Tips for Working with a Metal Lathe

Using a metal lathe requires proper knowledge, skills, and safety precautions. Here are some tips to keep in mind when working with a metal lathe:

1. Wear Safety Gear

Always prioritize safety when operating a metal lathe. Wear appropriate safety gear, such as safety glasses, gloves, and ear protection, to protect yourself from flying debris and loud noises.

Additionally, ensure that your work area is clean and well-lit to prevent accidents and injuries.

2. Secure the Workpiece Properly

Before starting, ensure that the workpiece is securely fastened to the lathe chuck or faceplate. A loose workpiece can cause imprecise cuts and accidents.

Use proper clamping techniques and ensure that the workpiece is centered and balanced to achieve accurate results.

3. Familiarize Yourself with the Lathe’s Controls

Take the time to understand and familiarize yourself with the controls of the metal lathe. Learn how to adjust the speed, feed rate, and tool position to achieve the desired cuts.

Refer to the lathe’s manual for guidance on proper operation and maintenance.

4. Start with Small, Simple Projects

If you’re new to metalworking or woodworking, start with small, simple projects to practice your skills and build confidence. Begin with designs that require basic cuts and gradually progress to more complex shapes and patterns.

Remember to take your time and focus on precision rather than rushing through the process.

Wrap-Up:

Metal lathes are versatile tools used in a wide range of industries, from manufacturing to woodworking. They offer precise shaping and forming capabilities, enabling users to create intricate designs and custom-made products. Whether you’re a professional engineer, a hobbyist, or a DIY enthusiast, incorporating a metal lathe into your workshop can open up endless possibilities for creativity and innovation. By understanding the applications and benefits of a metal lathe and following best practices, you can harness the full potential of this indispensable tool.

Key Takeaways: Why is a Metal Lathe Used?

- A metal lathe is used to shape and cut metal objects with precision.

- It allows for the creation of intricate and complex designs in metalwork.

- Using a metal lathe, you can create threads, grooves, and other custom features on metal parts.

- With the help of this tool, you can turn raw metal materials into finished products.

- Metal lathes are widely used in industries such as automotive, aerospace, and manufacturing.

Frequently Asked Questions

In this section, we will address some common questions about the usage of metal lathes.

How does a metal lathe work?

A metal lathe is a machine tool used to shape and cut metal. It uses a rotating workpiece and a cutting tool to remove material from the workpiece, creating the desired shape. The workpiece is clamped securely in place while the cutting tool moves along the workpiece, removing excess material. This process is controlled by a combination of manual adjustments and computerized controls, allowing for precise and accurate machining.

By rotating the workpiece at varying speeds and feeding the cutting tool at different rates, metal lathes can create a wide range of shapes, including cylindrical shapes, threads, and tapers. The versatility of metal lathes makes them invaluable in industries such as manufacturing, automotive, and aerospace.

What are the benefits of using a metal lathe?

Metal lathes offer several advantages that make them essential tools in metalworking:

1. Versatility: Metal lathes can be used to create a wide variety of shapes and sizes. They can cut threads, turn cylinders, and create precision parts with tight tolerances.

2. Precision: Metal lathes allow for precise machining, resulting in accurate and consistent parts. They can achieve tight tolerances, ensuring the parts fit together properly.

3. Efficiency: Metal lathes are designed to remove material quickly, improving productivity and reducing manufacturing time. They can handle larger workpieces, allowing for the production of complex components in a shorter amount of time.

4. Cost-effectiveness: By using a metal lathe, manufacturers can reduce the need for outsourcing parts. This saves time and money, as they can produce components in-house, ensuring quality control and reducing lead times.

What types of materials can be used with a metal lathe?

Metal lathes are primarily used for machining metals, including steel, aluminum, brass, and cast iron. These machines are designed to handle various materials, from soft metals to harder alloys. However, some metal lathes can also work with non-metal materials such as wood and plastics.

The specific type of material used depends on the project requirements. Harder metals may require more robust cutting tools and slower cutting speeds, while softer materials can be machined at higher speeds. It’s important to select the appropriate cutting tools and feed rates to achieve the desired results and prevent tool wear or damage.

What are the common applications of a metal lathe?

Metal lathes have a wide range of applications in various industries, including:

1. Manufacturing: Metal lathes are used in the production of precision parts, such as gears, shafts, and bushings. They are also used for turning, boring, and threading operations.

2. Automotive: Metal lathes are essential in automotive repair and maintenance. They are used for machining brake drums, rotors, engine components, and other vital parts.

3. Aerospace: Metal lathes play a crucial role in aerospace manufacturing, where precision and quality are paramount. They are used for creating complex components for aircraft engines, landing gear, and cockpit instruments.

4. Hobbyists and DIY enthusiasts: Metal lathes are also popular among hobbyists and those who enjoy DIY projects. They allow individuals to create customized parts and components for various projects, such as model engines and metal sculptures.

What safety precautions should be taken when using a metal lathe?

When operating a metal lathe, it is important to prioritize safety. Here are some essential safety precautions:

1. Proper Training: Ensure that operators have received appropriate training on how to use a metal lathe safely. This should include understanding the machine’s controls, safety features, and potential hazards.

2. Personal Protective Equipment (PPE): Always wear appropriate PPE, such as safety glasses, gloves, and ear protection, to protect against flying debris, oil splatters, and excessive noise.

3. Secure Workpiece: Before starting any machining operation, ensure that the workpiece is securely clamped in place. This prevents the workpiece from moving or becoming dislodged during machining.

4. Tool Inspection: Regularly inspect and maintain cutting tools to ensure they are in good working condition. Dull or damaged tools can cause accidents and produce poor-quality results.

5. Clean Work Area: Keep the work area clean and free of clutter. This reduces the risk of slips, falls, and accidents caused by obstruction or loose objects.

By following these safety measures, operators can prevent accidents and injuries while operating a metal lathe.

How to Use a Metal Lathe – Kevin Caron

Summary

Metal lathes are an important tool used in various industries for shaping and cutting metal. They have a rotating spindle that holds the metal workpiece and a cutting tool that shapes it. Lathes are used to create precise and intricate metal components for machines and other products.

Metal lathes are versatile machines that can produce a wide range of shapes and sizes. They are used in industries such as automotive, aerospace, and manufacturing. Lathes are essential for creating parts that require high precision and accuracy. They can also be used for repairs and modifications to existing metal components. Overall, metal lathes play a crucial role in the production of many everyday objects, from car parts to household appliances.