What exactly is a resaw bandsaw blade? Well, let me break it down for you! A resaw bandsaw blade is a special type of blade that is designed specifically for making long, straight cuts through thick pieces of wood. It’s like having a superhero blade for slicing through those tough materials!

You might be wondering, why is it called a “resaw” blade? Great question! The term “resaw” refers to the process of cutting a thick piece of wood into thinner slices. So, when you use a resaw bandsaw blade, you’re able to take a wide piece of wood and effortlessly transform it into multiple thinner boards.

Now, you may be thinking, “Why can’t I just use a regular bandsaw blade for resawing?” Well, my friend, that’s because resaw blades are specifically engineered to handle the high tension and stress of cutting through thick stock. They have a unique tooth pattern and a wider width, allowing them to efficiently remove material as you make those precision cuts.

So, if you’re looking to unlock the full potential of your bandsaw and tackle those resawing projects with ease, a resaw bandsaw blade is just what you need. Get ready to unleash your woodworking skills and create beautiful pieces with the help of this powerful tool!

What is a Resaw Bandsaw Blade?

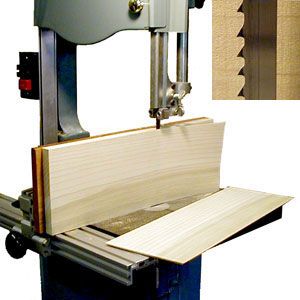

A resaw bandsaw blade is a specialized type of bandsaw blade designed for cutting thick pieces of wood into thinner sections. It is commonly used in woodworking and sawmills for tasks such as cutting veneers, bookmatching, and creating lumber with a smooth, even thickness. Resawing is the process of cutting a board or plank along its width to create multiple thinner pieces. This technique is particularly useful for maximizing the yield of expensive or rare wood, as it allows craftsmen to create multiple usable pieces from a single board.

Resaw bandsaw blades typically have a wide and deep gullet, or groove, that allows for efficient chip removal during the cutting process. They also have a low TPI (teeth per inch) count, usually between 3 and 6, which helps ensure a smooth and consistent cut. These blades are often made from high-quality carbon steel or bi-metal materials, which provide durability and resistance to wear and tear. Additionally, they may feature a variable tooth pattern, which helps optimize cutting performance across different types of wood.

When using a resaw bandsaw blade, it is important to properly set up and adjust the bandsaw to ensure optimal performance. This includes tensioning the blade correctly, aligning the blade guides, and setting the appropriate feed rate for the material being cut. Following manufacturer guidelines and best practices is crucial for achieving accurate and safe resaw cuts. It is also worth noting that while a resaw bandsaw blade can deliver excellent results, it does require skill and practice to use effectively. However, with the right techniques and equipment, resawing can be a valuable tool for woodworkers and sawmill operators.

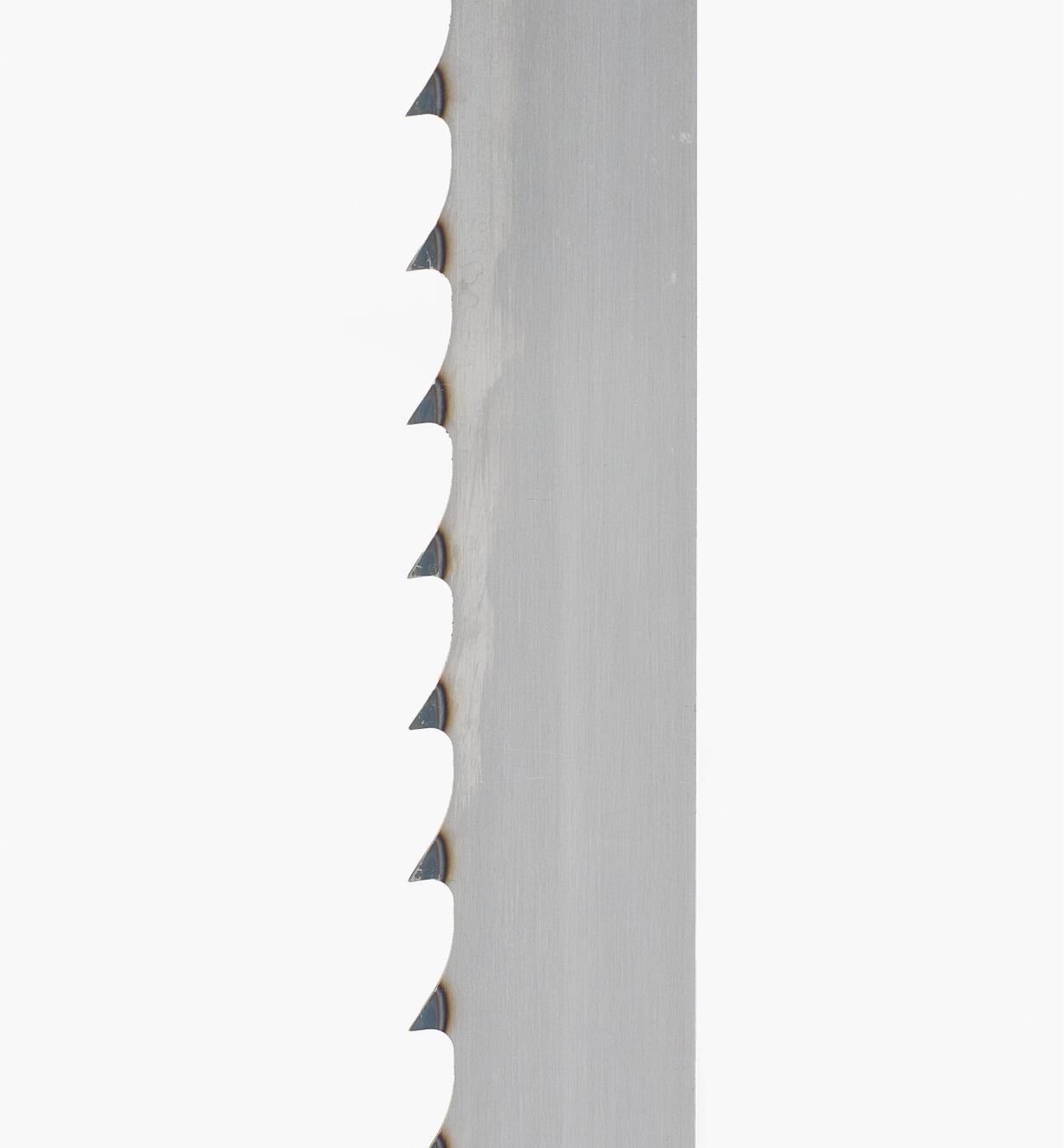

The Anatomy of a Resaw Bandsaw Blade

A resaw bandsaw blade consists of several key components that contribute to its cutting performance. These include:

- Blade Material: Resaw bandsaw blades are typically made from high-quality carbon steel or bi-metal materials. Carbon steel blades are more affordable and offer good cutting performance, while bi-metal blades provide enhanced durability and wear resistance.

- Blade Width: Resaw blades are available in a variety of widths, ranging from 1/2 inch to 2 inches or more. The width of the blade determines the minimum radius of a curve that can be cut and affects the overall stability during the resawing process.

- Teeth Per Inch (TPI): The TPI refers to the number of teeth found on one inch of the blade. Resaw blades typically have a low TPI count, typically between 3 and 6, which helps ensure a smooth and even cut.

- Tooth Pattern: Resaw blades can feature different tooth patterns, such as hook, raker, or skip, depending on the desired cutting performance. Some blades may even have a variable tooth pattern, which optimizes cutting performance across different wood species.

- Gullet: The gullet of a resaw blade is the groove between the teeth. Resaw blades typically have a wider and deeper gullet than standard blades to allow for efficient chip removal during the cutting process.

Understanding the various components of a resaw bandsaw blade is essential for selecting the right blade for specific cutting tasks and achieving optimal results.

The Benefits of Using a Resaw Bandsaw Blade

Using a resaw bandsaw blade offers several advantages and benefits in woodworking and sawmill applications:

1. Increased Material Yield:

One of the primary benefits of using a resaw bandsaw blade is the ability to maximize the yield from a single piece of wood. By cutting a thicker board into multiple thinner sections, woodworkers can obtain multiple usable pieces from a single board. This is particularly useful when working with expensive or rare wood.

2. Cost Savings:

Resawing with a bandsaw blade can help reduce material costs by making the most out of each piece of wood. By cutting thin slices from thicker stock, woodworkers can achieve the desired thickness without needing to purchase additional, more expensive materials.

3. Versatility:

A resaw bandsaw blade allows for a range of cutting techniques, from cutting veneers to creating bookmatched panels and lumber with consistent thickness. This versatility makes it a valuable tool for both small-scale woodworking projects and large-scale sawmill operations.

4. Smooth and Even Cuts:

Resaw blades are designed to produce smooth and even cuts, resulting in high-quality finished pieces. The wide gullets and low TPI count of these blades help reduce the chances of chip clogging, resulting in cleaner and more precise cuts.

5. Time Efficiency:

Resawing with a bandsaw blade is generally faster than other methods, such as using a planer or jointer, especially when dealing with larger or irregularly shaped pieces of wood. The wide blade and powerful motor of a bandsaw allow for efficient and precise resawing, saving time and effort.

Overall, a resaw bandsaw blade is a valuable tool for any woodworker or sawmill operator looking to maximize material yield, achieve smooth and even cuts, and improve overall efficiency in their woodworking projects.

Choosing the Right Resaw Bandsaw Blade

When selecting a resaw bandsaw blade, several factors should be considered to ensure optimal cutting performance:

1. Blade Width:

The width of the blade determines the minimum radius of a curve that can be cut and affects the stability during the resawing process. It is important to choose a blade width that matches the desired cutting requirements and the capabilities of the bandsaw being used.

2. Tooth Configuration:

Resaw blades can feature different tooth configurations, such as hook, raker, or skip. Each configuration has its own advantages and is suited for specific cutting tasks. For example, a hook-tooth blade with its deep gullets is ideal for resawing thick and dense hardwoods, while a skip-tooth blade with its wider tooth spacing is better suited for softer woods.

3. Blade Tension:

Proper blade tension is crucial for achieving accurate and smooth cuts during the resawing process. The tension should be adjusted according to the manufacturer’s guidelines to ensure the blade is not too loose or too tight.

4. Blade Material:

The material from which the blade is made can significantly impact its performance and durability. Carbon steel blades are more affordable and offer good cutting performance, while bi-metal blades provide enhanced durability and resistance to wear and tear.

5. Blade Maintenance:

Regular maintenance and cleaning of the blade are essential to maintain its cutting performance and extend its lifespan. This includes cleaning the blade after each use, checking for any signs of damage or wear, and ensuring proper tension and alignment.

Overall, selecting the right resaw bandsaw blade involves considering the specific cutting requirements, the bandsaw being used, and the desired quality of the finished pieces. By choosing the appropriate blade, woodworkers can achieve optimal cutting performance and maximize the benefits of resawing.

Common Techniques and Tips for Resawing with a Bandsaw

Resawing with a bandsaw requires skill and practice to achieve optimal results. By following the techniques and tips below, woodworkers can improve their resawing capabilities:

1. Blade Selection:

Choose the right resaw bandsaw blade based on the desired cutting requirements and the type of wood being cut. Consider factors such as blade width, tooth configuration, and material to ensure optimal cutting performance.

2. Blade Tension and Tracking:

Properly tension the blade according to the manufacturer’s guidelines. Ensure the blade is tracking correctly on the bandsaw’s wheels to prevent slipping or damage during cutting.

3. Blade Guides and Bearings:

Align and adjust the blade guides and bearings to provide proper support and reduce friction during the cutting process. Check for any wear or damage to the guides and replace them if necessary.

4. Feed Rate:

Control the feed rate by applying even and consistent pressure on the workpiece. Avoid forcing the wood through the blade, as this can lead to poor cut quality and potential safety hazards.

5. Blade Drift:

Take into account the natural tendency of bandsaw blades to drift to one side during cutting. Adjust the fence or use a dedicated resaw fence to compensate for this drift and ensure straight cuts.

6. Safety Precautions:

Always prioritize safety when resawing with a bandsaw. Use appropriate personal protective equipment, such as safety glasses and hearing protection. Keep hands and fingers away from the blade and maintain a firm grip on the workpiece.

By following these techniques and tips, woodworkers can improve their resawing skills and achieve consistent, high-quality results.

Conclusion

Resaw bandsaw blades are an essential tool for woodworkers and sawmill operators looking to maximize material yield, achieve smooth and even cuts, and improve overall efficiency. These specialized blades, with their wide gullets and low TPI count, are designed to cut thick pieces of wood into thinner sections. By selecting the right blade, adhering to proper techniques, and prioritizing safety, woodworkers can achieve accurate and high-quality resaw cuts. Whether it’s creating veneers, bookmatching, or maximizing the yield of expensive wood, a resaw bandsaw blade is a valuable asset in any woodworking arsenal.

Key Takeaways: What is a Resaw Bandsaw Blade?

- A resaw bandsaw blade is a special type of blade used in bandsaws to cut thick pieces of wood into thinner slices for various woodworking projects.

- It is designed with large, closely spaced teeth to efficiently remove material while reducing the chance of clogging and heat buildup.

- Resaw blades are typically wider and have a lower TPI (teeth per inch) count compared to regular bandsaw blades.

- They are ideal for cutting lumber, veneers, and other materials that require precise and smooth cuts.

- Choosing the right resaw bandsaw blade depends on factors such as the type of material, desired thickness, and the bandsaw’s power and size.

Frequently Asked Questions

Have questions about resaw bandsaw blades? We’ve got you covered! Check out these informative Q&A pairs to learn more about what resaw bandsaw blades are and how they are used.

How are resaw bandsaw blades different from regular bandsaw blades?

Resaw bandsaw blades are specifically designed for making long, straight cuts through thick materials. Unlike regular bandsaw blades, which are ideal for curved cuts or intricate patterns, resaw blades have a wider blade width and fewer teeth per inch. This design allows them to efficiently remove large amounts of material and maintain a straight, consistent cut during the resawing process.

Regular bandsaw blades are often narrower and have a higher tooth count, which makes them better suited for intricate cuts or cutting thinner materials. Resaw blades, on the other hand, are designed to handle the rigors of cutting thick stock, such as boards or planks, with precision and efficiency.

What is the primary purpose of using a resaw bandsaw blade?

The primary purpose of using a resaw bandsaw blade is to transform thick lumber into thinner pieces by cutting it along its thickness. This process is called resawing, and it is commonly used in woodworking for tasks like creating veneers, book-matched panels, or obtaining multiple thinner boards from a single thick piece. Resawing allows woodworkers to maximize the use of their lumber and create beautiful, dimensionally stable pieces.

By using a resaw bandsaw blade, woodworkers can achieve clean, straight cuts that minimize material waste and provide greater control and accuracy compared to other cutting methods. It is a versatile tool that is highly valued in the woodworking community for its ability to transform thick stock into usable and attractive pieces of lumber.

Are resaw bandsaw blades suitable for cutting metal or other materials?

Resaw bandsaw blades are primarily designed for cutting wood and may not be suitable for cutting metal or other materials. The tooth geometry, tooth set, and the material composition of resaw blades are optimized for efficient cutting through wood fibers, which have a different hardness and composition compared to metals or other materials.

Using a resaw bandsaw blade to cut metal or other materials may result in premature blade wear, blade damage, or inefficient cutting. It is generally recommended to use specialized blades designed for cutting specific materials, such as metal-cutting bandsaw blades, when working with materials other than wood.

What factors should I consider when choosing a resaw bandsaw blade?

When choosing a resaw bandsaw blade, several factors should be taken into consideration to ensure the best cutting performance. One essential factor is the blade’s width, which should be appropriate for the thickness of the material you plan to cut. A wider blade can handle thicker stock more efficiently, while a narrower blade is better suited for thin stock.

The tooth count or the number of teeth per inch is another crucial consideration. Blades with a lower tooth count, such as three to four teeth per inch, are better suited for resawing thick stock, as they can remove material more effectively. Higher tooth counts, such as six to eight teeth per inch, are more suitable for cutting thinner stock or making smoother cuts. Lastly, consider the blade’s tooth geometry, tooth set, and material composition, as these factors can affect the blade’s cutting ability and overall performance.

How can I maintain and prolong the lifespan of my resaw bandsaw blade?

Proper maintenance is crucial for prolonging the lifespan of your resaw bandsaw blade. One important aspect is keeping the blade clean and free from pitch or sap buildup, as these can hinder its cutting performance. Regularly wiping the blade with a clean cloth or using a blade cleaning solution can help remove any residue.

Another key factor is proper blade tension. It’s essential to ensure that the blade is correctly tensioned according to the manufacturer’s guidelines. Insufficient tension can lead to blade flutter or breakage, while excessive tension can cause premature blade wear. Additionally, using appropriate cutting lubricants, ensuring proper feed rate, and avoiding excessive heat build-up during cutting can also contribute to prolonging the blade’s lifespan.

Summary:

A resaw bandsaw blade is a special type of blade used in bandsaws to cut wood into thinner pieces. It has a narrow width and sharp teeth, perfect for making precise and smooth cuts. The blade’s design allows for efficient cutting and reduces waste by using up less material. Resawing is particularly useful for creating veneers, where thin strips of wood are needed. It is a handy tool for woodworkers and can be used for various projects like making furniture or crafting intricate designs.

In conclusion, a resaw bandsaw blade is a valuable tool that helps woodworkers create thinner pieces of wood with precision and efficiency. By understanding its purpose and how it works, you can unlock a whole new level of woodworking possibilities. So, go ahead and give resawing a try in your next woodworking project!