Have you ever wondered what all those knobs and levers on a lathe do? Well, let’s start by answering the question, “What is a lathe axis?” A lathe axis refers to the different directions in which the cutting tool on a lathe can move. These axes allow the lathe to create various shapes and features on a workpiece.

Imagine you’re holding a piece of wood in your hand, and you want to shape it into a beautiful cylindrical object. Now, the lathe comes into play. It’s like having a magic machine that can spin the wood while you shape it with a cutting tool. But to make precise cuts, you need to control the movement of the tool in different directions.

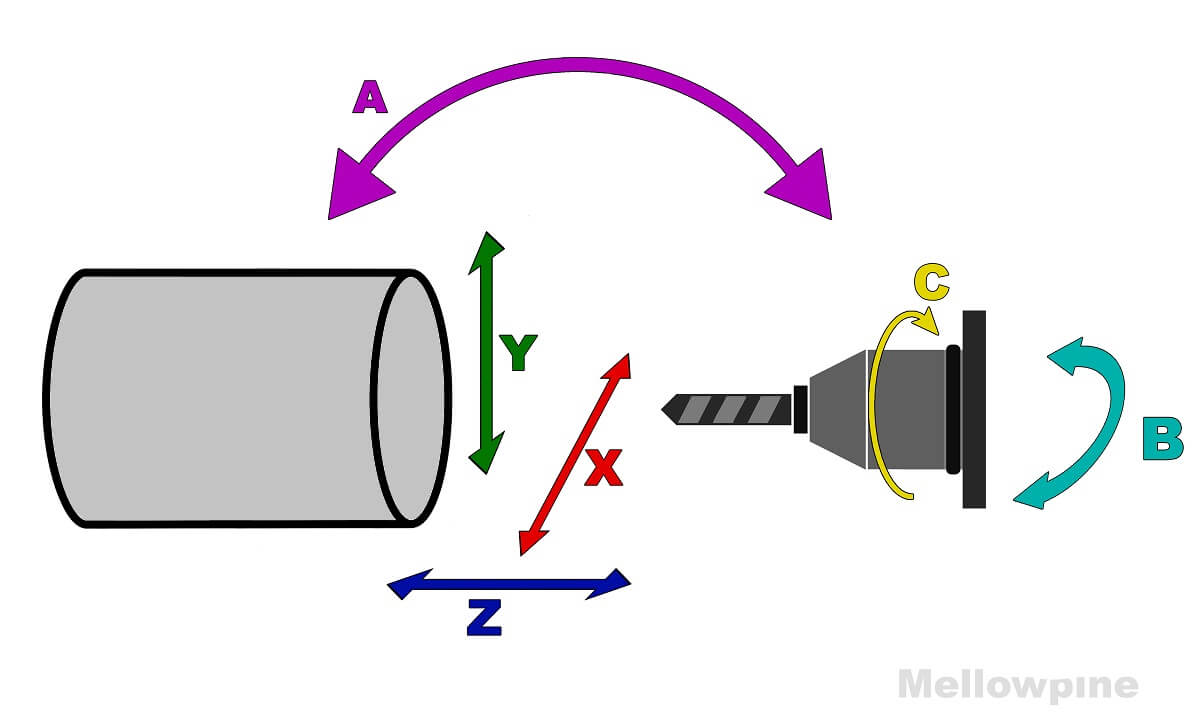

So, what are these directions? Well, there are typically three main axes on a lathe: the X-axis, the Y-axis, and the Z-axis. Each axis represents a specific direction of movement for the cutting tool. Understanding how these axes work together is key to operating a lathe effectively and creating intricate designs.

Now that we have a basic understanding of what a lathe axis is, let’s dive deeper into each axis and explore their functions and capabilities. So, buckle up and get ready to unravel the secrets behind the fascinating world of lathe machining!

Understanding the Lathe Axis: What You Need to Know

Welcome to this comprehensive guide on the lathe axis! In this article, we will dive deep into the concept of the lathe axis, its significance, and how it is used in various industries. Whether you’re a machinist or simply curious about the mechanics behind lathe machines, this article will provide you with valuable insights. So, let’s get started!

What is a Lathe Axis?

One of the primary components of a lathe machine is the lathe axis. The lathe axis refers to the direction of movement or rotation of the workpiece that is being machined. In a lathe machine, the workpiece is typically mounted on a spindle and rotated rapidly against cutting tools to shape or remove material. The direction or axis along which the workpiece rotates determines the type of cutting or machining operation that can be performed.

The most common types of lathe axes are the X-axis, Z-axis, and sometimes the Y-axis. The X-axis represents the horizontal movement of the cutting tool, allowing it to traverse along the workpiece’s length. The Z-axis represents the longitudinal movement of the cutting tool, enabling it to move towards or away from the workpiece’s center. In some cases, the Y-axis is also utilized, which represents the vertical movement of the cutting tool, allowing it to move up or down.

The lathe axis plays a crucial role in determining the precision and accuracy of the machining process. By controlling the movement of the cutting tool along the X, Y, and Z axes, machinists can create intricate designs, achieve tight tolerances, and produce high-quality finished products.

The X-Axis: Horizontal Precision Machining

The X-axis is responsible for the horizontal movement of the cutting tool relative to the workpiece. It allows the cutting tool to traverse along the workpiece’s length, enabling precision machining operations such as facing, turning, and grooving. By controlling the X-axis movement, machinists can achieve accurate and uniform cuts, ensuring the desired dimensions and surface finish are achieved.

When using the X-axis, it is crucial to consider factors such as tool feed rate, cutting speed, and depth of cut to optimize the machining process. Furthermore, the X-axis movement is often combined with other lathe axes, such as the Z-axis, to perform complex machining operations like taper turning or thread cutting.

The X-axis offers great flexibility and versatility in machining a wide range of workpieces. Whether you’re working with cylindrical, conical, or even irregularly shaped workpieces, the X-axis allows machinists to achieve precise and repeatable cuts, making it an essential axis in lathe machining.

The Z-Axis: Longitudinal Machining for Depth Control

The Z-axis is responsible for the longitudinal movement of the cutting tool relative to the workpiece. It enables the cutting tool to move towards or away from the workpiece’s center, controlling the depth of the cut. This axis is crucial when performing operations such as facing, turning, boring, and drilling.

By controlling the Z-axis movement, machinists can achieve precise depth control, ensuring consistent and accurate machining throughout the workpiece. Adjusting the Z-axis allows for the creation of grooves, chamfers, and other complex geometries with tight tolerances.

When working with the Z-axis, machinists must consider factors such as tool selection, tool geometry, and cutting parameters to ensure optimal results. By mastering the Z-axis, machinists can achieve excellent surface finishes, tight tolerances, and efficient material removal.

The Y-Axis: Vertical Precision and Versatility

Although the X and Z axes are the most commonly used in lathe machining, some machines also feature the Y-axis. The Y-axis represents the vertical movement of the cutting tool, enabling it to move up or down. While the Y-axis is not as prevalent as the X and Z axes, it offers additional precision and versatility in certain applications.

The Y-axis can be used for operations such as drilling holes at different heights or machining angled surfaces. It allows for the creation of complex geometries and contours that are challenging to achieve with only the X and Z axes. The Y-axis is particularly useful in industries such as aerospace, automotive, and medical, where intricate parts and curved surfaces are common.

By incorporating the Y-axis into the machining process, machinists can expand their capabilities and take on more complex projects. However, it is important to note that not all lathe machines are equipped with a Y-axis, and its usage depends on the specific requirements of the workpiece and the machining operation.

Advantages of Using Lathe Axes

The utilization of lathe axes provides several advantages in the machining industry:

- Precision: By controlling the movement along the X, Y, and Z axes, machinists can achieve high precision and accuracy in their machining operations.

- Versatility: The ability to move the cutting tool in different directions enables machinists to perform a wide range of machining tasks and create intricate designs.

- Efficiency: Lathe axes facilitate efficient material removal, reducing machining time and increasing productivity.

- Flexibility: With the ability to move the cutting tool in multiple directions, machinists can easily adapt to various workpiece geometries and machining requirements.

- Consistency: The controlled movement along the lathe axes ensures consistent cuts and surface finishes, resulting in uniform and high-quality finished products.

Conclusion

The lathe axis is a fundamental concept in the world of machining. Understanding the different lathe axes, such as the X, Z, and sometimes Y, allows machinists to control the movement of the cutting tool and achieve precise and accurate machining results. By leveraging the advantages offered by lathe axes, machinists can create intricate designs, achieve tight tolerances, and produce high-quality finished products efficiently and consistently. So, whether you’re a machinist or simply fascinated by the mechanics of lathe machines, understanding the lathe axis is key to unlocking the full potential of this indispensable machining tool.

What is Lathe Axis?

- The lathe axis refers to the directions along which a lathe machine can move.

- It typically consists of three axes: X, Y, and Z.

- The X-axis controls the horizontal movement of the cutting tool.

- The Y-axis controls the vertical movement of the cutting tool.

- The Z-axis controls the axial or longitudinal movement of the workpiece.

Frequently Asked Questions

In the world of machining, understanding the different axes of a lathe is crucial. Here are some commonly asked questions related to lathe axis.

1. How many axes are there in a lathe?

A lathe typically has two axes: the X-axis and the Z-axis. The X-axis moves the cutting tool horizontally, while the Z-axis moves it vertically. These axes allow for precise control over the position of the cutting tool, enabling the creation of various shapes and contours.

Some advanced lathes may have additional axes, such as the Y-axis for angled cuts or the C-axis for rotating the workpiece. However, the X and Z axes are the most fundamental axes in lathe operations.

2. What is the purpose of the X-axis in a lathe?

The X-axis in a lathe is responsible for the longitudinal or horizontal movement of the cutting tool. It allows the tool to move along the length of the workpiece, shaping it as desired. Think of it as the left-right movement of the tool.

By adjusting the X-axis, machinists can determine the diameter, length, and shape of the workpiece. This axis plays a crucial role in achieving precision and accuracy in lathe operations.

3. How does the Z-axis function in a lathe?

The Z-axis in a lathe controls the vertical or axial movement of the cutting tool. It determines how deep the tool penetrates into the workpiece, thereby determining the thickness and depth of the cut. Picture it as the up-down movement of the tool.

By adjusting the Z-axis, machinists can create different profiles, contours, and features on the workpiece. This axis allows for precise control over the depth of the cut, producing the desired shape and dimensions.

4. Can you explain the difference between manual and CNC lathe axes?

In a manual lathe, the X and Z axes are controlled by hand, using handwheels or levers. This requires the operator to physically turn the wheels to adjust the tool position. Manual lathes offer greater hands-on control, but they can be more time-consuming.

On the other hand, in a CNC (Computer Numerical Control) lathe, the X and Z axes are controlled by a computer program. The operator inputs the desired dimensions and the lathe automatically moves the tool to the correct position. CNC lathes provide increased precision, speed, and repeatability.

5. What are the advantages of having additional axes in a lathe?

Having additional axes in a lathe opens up a world of possibilities. For example, the addition of a Y-axis allows for angled cuts and complex shapes that are not possible with just the X and Z axes. This enhances the versatility and flexibility of the lathe.

Moreover, the C-axis—found in some advanced lathes—enables the rotation of the workpiece. This is especially useful for machining cylindrical parts or creating intricate patterns. Additional axes offer greater freedom in machining operations, leading to more complex and precise workpieces.

Summary

So, what is lathe axis? Basically, it’s the different directions in which a lathe machine can move. There are two main types of axis: the X-axis and the Z-axis. The X-axis moves the cutting tool back and forth, while the Z-axis moves the workpiece in and out. Understanding the lathe axis is important for operating a lathe machine efficiently and producing accurate and precise work. By knowing how the axis work, you’ll be able to create different cuts and shapes on your workpiece. So, next time you see a lathe machine in action, remember the X-axis and the Z-axis that make it all possible!