Have you ever wondered what kind of steel table saw blades are made of? Well, buckle up because we’re about to dive into the fascinating world of these powerful cutting tools! Table saw blades are crafted from a special type of steel that combines strength, durability, and sharpness to ensure precise and efficient cutting. So, what exactly is this steel made of? Let’s find out!

When it comes to table saw blades, the most common type of steel used is called high-speed steel (HSS). HSS is a blend of various elements, including carbon, tungsten, chromium, and vanadium, all working together to create a strong and tough material. This unique steel composition allows table saw blades to withstand the intense pressures and friction generated during cutting.

But wait, there’s more! Some table saw blades are made from an even more advanced steel known as carbide-tipped steel. This steel takes things up a notch by incorporating tiny pieces of tungsten carbide along the blade’s cutting edge. This addition greatly enhances the blade’s hardness and sharpness, making it ideal for cutting through tough materials like hardwood and metal.

Now that you have a better understanding of the materials behind table saw blades, you’ll be able to appreciate the precision and power these tools bring to your woodworking projects. Whether it’s HSS or carbide-tipped steel, these blades are designed to slice through various materials with ease, making your woodworking endeavors a breeze! So, let’s get out there and make some impressive cuts!

What Kind of Steel Are Table Saw Blades Made Of?

Table saw blades are essential tools for woodworking and cutting various materials with precision. But have you ever wondered what kind of steel is used to make these blades? In this article, we will delve into the world of table saw blades and explore the different types of steel used in their construction.

The Importance of Steel in Table Saw Blades

Steel is the primary material used in the manufacturing of table saw blades due to its exceptional strength, durability, and resistance to wear. The choice of steel for a table saw blade is crucial as it directly impacts the blade’s performance and lifespan. Different types of steel alloys offer various properties and characteristics, making them suitable for specific cutting tasks and applications.

Manufacturers carefully select the type of steel used in table saw blades based on factors such as hardness, toughness, corrosion resistance, and heat resistance. By choosing the right steel, they can ensure that the blades can withstand the high-speed rotation and cutting forces generated during use, resulting in cleaner cuts and longer blade life.

Types of Steel Used in Table Saw Blades

1. High-Speed Steel (HSS): High-speed steel is one of the most common types of steel used in table saw blades. It is a durable and heat-resistant alloy that retains its hardness even at high temperatures. HSS blades are ideal for cutting materials such as wood, plastic, and non-ferrous metals. They offer good edge retention and can withstand the rigors of heavy-duty cutting tasks.

2. Carbide-Tipped Steel: Carbide-tipped table saw blades are known for their exceptional cutting performance and longevity. These blades have a steel body with small tungsten carbide teeth attached to the cutting edge. Carbide-tipped blades are highly resistant to wear, heat, and corrosion, making them suitable for cutting hard and abrasive materials like hardwood, plywood, and laminate.

3. Carbon Steel: Carbon steel is an affordable option for table saw blades. It offers decent hardness and sharpness but is not as durable as high-speed steel or carbide-tipped blades. Carbon steel blades are suitable for light to moderate cutting tasks and are commonly used in DIY and hobbyist woodworking projects.

Choosing the Right Table Saw Blade

When selecting a table saw blade, it’s crucial to consider the specific cutting tasks and materials you will be working with. Here are a few tips to help you choose the right blade:

- Determine the type of material you will primarily be cutting (e.g., wood, metal, plastic).

- Consider the thickness and hardness of the material, as different blades are designed for different densities.

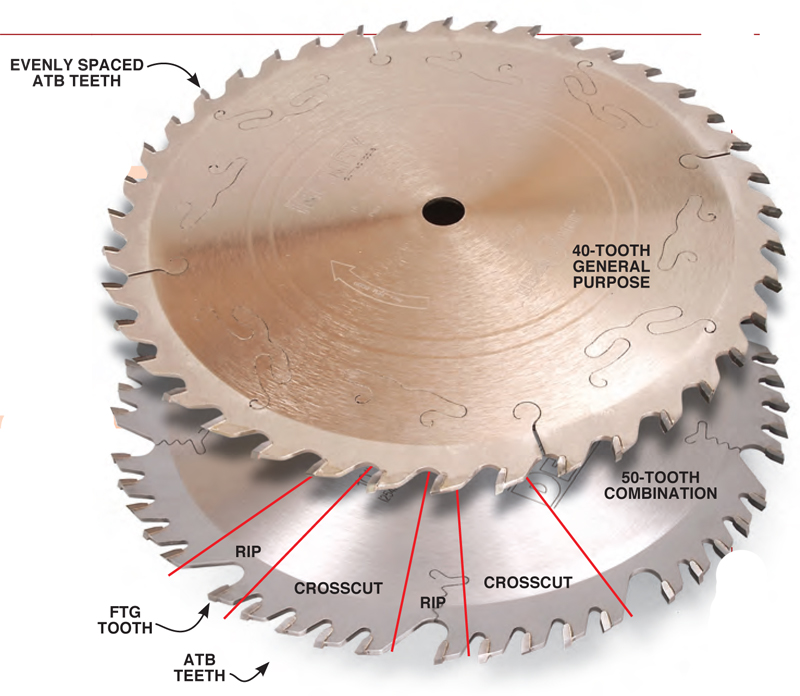

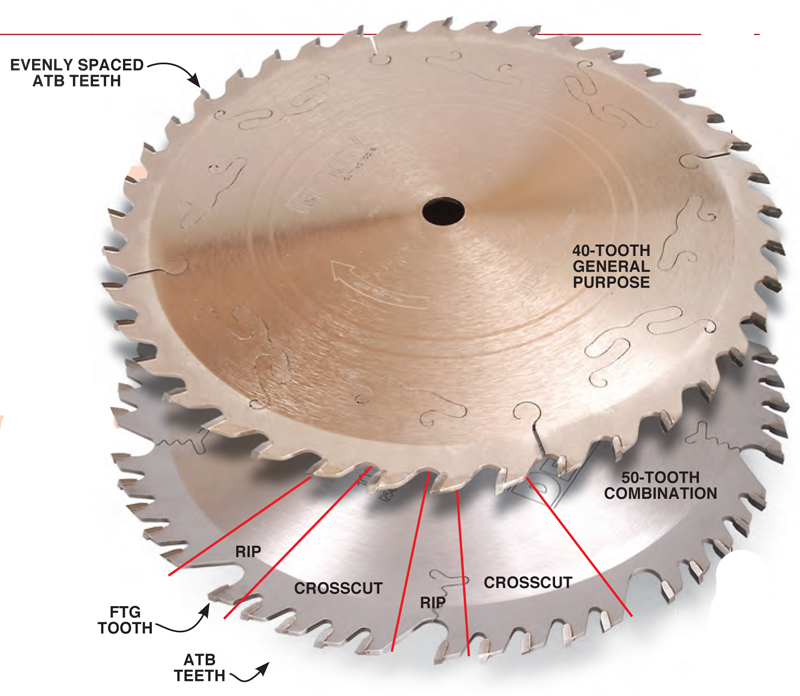

- Choose a blade with the appropriate number of teeth for the desired finish (more teeth for finer cuts, fewer teeth for faster cuts).

- Decide between a ripping blade (for cutting along the grain) or a crosscutting blade (for cutting across the grain).

- Check the blade’s compatibility with your table saw’s arbor size and RPM requirements.

Conclusion

Table saw blades are made from different types of steel, each offering its unique set of properties and benefits. High-speed steel provides excellent durability and heat resistance, while carbide-tipped blades offer superior cutting performance and longevity. For lighter tasks, carbon steel blades can be a cost-effective choice. By selecting the right blade for your cutting needs, you can achieve precise, clean cuts and optimize the lifespan of your table saw blade.

Key Takeaways: What Kind of Steel are Table Saw Blades Made Of?

Table saw blades are usually made of high-quality, high-carbon steel.

The steel used in table saw blades should be hardened to withstand the rigors of cutting through various materials.

Some table saw blades are also coated with carbide or other materials to enhance their durability and cutting performance.

To ensure safety and optimal cutting results, it’s important to choose a table saw blade made of the right type and grade of steel.

Understanding the composition and characteristics of different types of steel can help you select the best table saw blade for your specific cutting needs.

Frequently Asked Questions

Welcome to our FAQ section where we answer some commonly asked questions about the steel used in table saw blades!

1. What type of steel are table saw blades typically made of?

Table saw blades are typically made from high-speed steel (HSS) or carbide-tipped steel. HSS blades are made from a combination of steel and other elements like tungsten, molybdenum, and chromium. This composition makes the blades strong, heat-resistant, and able to withstand high speeds. On the other hand, carbide-tipped blades have carbide inserts attached to the blade teeth, which provide exceptional cutting performance and durability.

In summary, while HSS blades are commonly used for standard woodworking applications, carbide-tipped blades are preferred for more demanding tasks like cutting through hardwood or abrasive materials.

2. How does the type of steel affect the overall performance of a table saw blade?

The type of steel used in a table saw blade greatly influences its performance. HSS blades, thanks to their unique composition, offer good heat resistance and durability. They are suitable for most woodworking tasks, especially when cutting softwoods or non-abrasive materials. However, they may not be as effective when cutting through harder woods or materials with high abrasiveness.

On the other hand, carbide-tipped blades, with their carbide inserts, provide excellent cutting performance and longevity. They can withstand the demands of cutting hardwoods, laminates, and even certain metals. They remain sharp for a longer time compared to HSS blades and are less likely to dull quickly. However, carbide-tipped blades can be more expensive than HSS blades, making them a better choice for professionals or those frequently working with challenging materials.

3. Can I use a table saw blade made for one type of steel on a different material?

While it is possible to use a table saw blade made for one type of steel on a different material, it may not yield the best results. For example, using an HSS blade designed for cutting softwoods on hardwoods or metals may cause the blade to dull quickly and produce less-than-desirable cuts. Similarly, using a carbide-tipped blade designed for cutting hardwoods on softer materials may result in over-cutting.

It’s important to choose a table saw blade specifically designed for the material you intend to cut. This ensures optimal performance, longevity, and quality of cuts. There are various types of blades available for different materials, so it’s worth investing in the right blade for your specific needs.

4. How can I determine the type of steel used in a table saw blade?

Determining the type of steel used in a table saw blade can be challenging without proper documentation or labeling. However, there are a few clues that can help you make an educated guess:

1. Check the packaging or product description: Manufacturers often provide information about the blade’s material composition. Look for terms like “HSS,” “carbide-tipped,” or specific steel grades.

2. Examine the blade’s color: HSS blades typically have a silver or gray color, while carbide-tipped blades may have a darker color due to the carbide inserts.

3. Consider the price: Carbide-tipped blades are generally priced higher than HSS blades due to their enhanced cutting performance and longevity.

If you’re still uncertain about the type of steel, reach out to the manufacturer or consult with a knowledgeable professional who can help you identify the blade’s composition accurately.

5. Are there any maintenance tips for table saw blades made of different types of steel?

Maintaining table saw blades, regardless of the type of steel, is crucial for optimal performance and longevity. Here are some maintenance tips:

1. Clean the blade regularly: Remove any resin, pitch, or sawdust buildup from the blade using a mild cleaner and a soft brush. This helps prevent residue from affecting the blade’s cutting ability.

2. Keep the blade sharp: Use a sharpening tool or take the blade to a professional sharpening service when it starts to dull. Keeping the blade sharp ensures clean and efficient cuts.

3. Store the blade properly: When not in use, store the blade in a clean and dry area. Consider using blade protectors or cases to prevent damage or accidents.

4. Follow the manufacturer’s instructions: Different blades may have specific maintenance requirements, so it’s essential to follow the manufacturer’s guidelines for cleaning, sharpening, and overall care.

By following these maintenance tips, you can maximize the lifespan and performance of your table saw blades, regardless of the type of steel they’re made of.

Summary

So, to sum it up, table saw blades are usually made of high-speed steel or carbide. High-speed steel blades are more affordable but may not last as long as carbide blades. On the other hand, carbide blades are more expensive but offer better durability and can cut through tough materials like hardwood and metal. It’s important to choose the right blade for your needs and always prioritize safety when operating a table saw.