So you’re ready to tackle a project that involves using a drill press? That’s awesome! But before you dive right in, let’s take a moment to talk about what should have occurred before you use the drill press. Trust me, taking a few precautions beforehand can make all the difference in ensuring a safe and successful woodworking experience.

First things first, when it comes to using a drill press, safety should always be a top priority. Before you even think about firing up that drill press, make sure you’re wearing the proper safety gear, like safety glasses and hearing protection. Safety first, right?

Now, let’s talk about preparing your materials. Before using the drill press, you should have selected the appropriate drill bit for the task at hand. Whether you’re drilling into wood, metal, or any other material, choosing the right drill bit is crucial for a clean and accurate result. So, take a moment to double-check that you have the correct bit in place.

Now that you know what should have occurred before using the drill press, you’re one step closer to becoming a woodworking pro. Just remember, taking the time to prioritize safety and prepare your materials will set you up for success with your drill press projects. So, let’s get drilling!

What You Need to Know Before Using a Drill Press

Using a drill press can be a versatile and efficient way to tackle various projects, from woodworking to metalworking. However, before you start drilling away, there are several crucial steps and considerations that should be taken into account to ensure both safety and optimal results. In this article, we will delve into what should have occurred before you use the drill press, providing you with valuable information and tips to make your drilling experience successful.

Understanding the Basics of a Drill Press

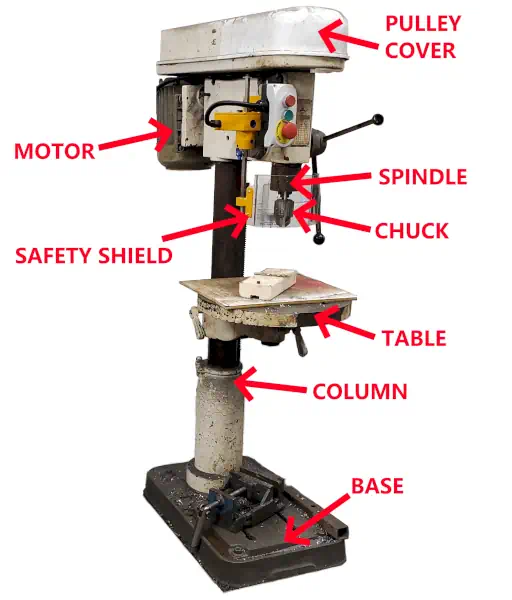

Before you even think about using a drill press, it’s essential to have a clear understanding of the basics. A drill press consists of a motor, a chuck, a spindle, and a drill bit. The motor powers the drill press, while the chuck holds the various drill bits that can be used for different purposes. The spindle, controlled by the motor, is responsible for driving the drill bit into the material you’re working on.

When using a drill press, it’s crucial to know the various parts and their functions to ensure smooth operation and avoid any accidents. Familiarize yourself with the key elements of the drill press, including the depth stop, speed control, and table adjustments. Understanding how these components work will help you navigate the drill press with confidence and precision.

Preparing Your Workspace

Creating a well-organized and safe workspace is paramount before starting any drilling project. Begin by clearing the area of any objects that might obstruct your movement or cause accidents. Remove any loose items, such as tools, and ensure that the floor is clean and free from debris.

Next, set up the drill press on a stable and level surface. If necessary, use shims or adjustable feet to ensure it sits securely. Check that the drill press is properly aligned and tightened, minimizing the risk of any wobbling or vibrations during operation.

Finally, evaluate your lighting conditions. Adequate lighting is essential for accurate drilling and maintaining visibility of the workpiece. Consider using additional lighting, such as a task light, to illuminate your workspace effectively.

Choosing the Right Drill Bit and Speed

One of the most critical factors that should have occurred before using a drill press is selecting the appropriate drill bit and speed for the material you’re working with. Different materials require specific drill bits to achieve optimal results, such as wood bits for woodworking projects and metal bits for metalworking.

Additionally, adjusting the speed of the drill press is crucial. The speed determines how fast the drill bit rotates, and choosing the right speed helps prevent burning or damaging the material. Consult the manufacturer’s guidelines or charts that provide recommended speeds according to the material you’re drilling into.

It’s also worth noting that certain drill presses offer variable speed settings, allowing you to adjust the rotation speed accordingly. Take advantage of this feature if available to match the needs of your specific project.

Ensuring Proper Safety Measures

Prioritizing safety should always be a top concern before using any power tools, and the drill press is no exception. Several safety measures should be taken to protect yourself and those around you.

First, wear appropriate personal protective equipment (PPE), including safety glasses or goggles to shield your eyes from any flying debris. Depending on the project, consider wearing a dust mask to avoid inhaling particles, and use ear protection to minimize noise exposure.

Furthermore, it’s vital to secure your workpiece properly to prevent it from shifting or rotating during drilling. Use clamps or vices to secure the material firmly, ensuring it remains stable throughout the process.

Lastly, always make sure the drill press is switched off and unplugged when not in use. This prevents any accidental activation or injury when you’re not directly handling the machine.

Maintaining and Cleaning Your Drill Press

Regular maintenance and cleaning are crucial to keep your drill press in optimal condition and ensure its longevity. After each use, clean the drill press, eliminating any debris or dust that may have accumulated during operation. Wipe down the machine with a soft cloth or brush, paying attention to the chuck, spindle, and motor housing.

Inspect all moving parts for any signs of damage or wear. Lubricate the necessary components as recommended by the manufacturer to keep the mechanisms running smoothly. Regularly check the belts for tension and adjust them if needed, ensuring optimal performance.

Additionally, it’s essential to periodically check and tighten any loose bolts or fasteners. This prevents any potential hazards during operation, such as parts becoming dislodged or detached.

Expanding Your Knowledge and Skills

Finally, don’t limit yourself to the basic knowledge and skills of using a drill press. There’s always room for growth and improvement. Expand your expertise by exploring different drilling techniques, experimenting with various drill bits, and learning about the capabilities of your specific drill press model.

Consider joining woodworking or metalworking communities, either online or in-person, where you can exchange ideas, ask questions, and gain valuable insights from experienced individuals. Engaging in workshops or courses can also provide hands-on experience and guidance to enhance your drilling abilities.

Remember, the more you invest in learning and practicing, the more confident and skilled you will become in utilizing the drill press to its full potential.

Common Mistakes to Avoid When Using a Drill Press

While understanding what should have occurred before using a drill press sets a solid foundation for a successful drilling experience, it’s equally important to steer clear of potential mistakes. Let’s explore some common errors to avoid when operating a drill press.

Not Wearing Proper Safety Gear

One of the most crucial mistakes to avoid is neglecting to wear the appropriate safety gear. Failing to use safety glasses or goggles can result in severe eye injuries from flying debris or wood chips. Additionally, skipping ear protection can lead to hearing damage due to the loud noise generated by the drill press.

Remember to always prioritize safety and wear the necessary gear to protect yourself from potential hazards and injuries.

Using the Wrong Drill Bit or Speed

Using the wrong drill bit or speed for the material you’re working with can lead to poor results, damaged material, or even accidents. Each material requires a specific type of drill bit, such as High-Speed Steel (HSS) bits for metal or Brad Point bits for woodworking.

Additionally, selecting the incorrect speed can cause the drill bit to burn the material or break prematurely. Consult the manufacturer’s guidelines or refer to speed charts to ensure you choose the appropriate drill bit and speed for your project.

Ignoring Proper Workpiece Clamping

Neglecting to securely clamp your workpiece can result in it shifting or spinning during drilling, leading to inaccuracies or accidents. Always use clamps or vices to hold the material firmly in place, ensuring stability and precision throughout the drilling process.

Drilling Without Clear Visibility

Proper lighting is crucial when using a drill press. Insufficient lighting can make it challenging to see the workpiece clearly, resulting in imprecise drilling. Ensure that your workspace is well-lit and consider using additional lighting, such as a task light, to illuminate the area effectively.

Not Maintaining and Cleaning the Drill Press

Neglecting regular maintenance and cleaning can lead to decreased performance and potential issues with your drill press. Over time, debris and dust can accumulate in the machine, affecting its functionality. Make it a habit to clean the drill press after each use, inspect and lubricate moving parts, and tighten any loose bolts or fasteners.

By avoiding these common mistakes and adhering to proper usage techniques, you can maximize the efficiency and longevity of your drill press while ensuring your safety and the quality of your work.

Additional Tips for Using a Drill Press

Now that we’ve covered what should have occurred before using a drill press and common mistakes to avoid, let’s explore some additional tips to enhance your drilling experience:

Use a Drill Press Vise or Clamp

When drilling small or irregularly shaped objects, a drill press vise or clamp can provide additional stability and precision. This ensures that the material remains fixed in position throughout the drilling process, allowing for clean and accurate holes.

Perform Test Drills

If you’re unsure about the speed or the material’s compatibility with the drill bit, it’s always a good idea to perform test drills on scrap pieces. This allows you to assess the speed, bit choice, and technique before proceeding with your actual project, reducing the risk of errors or damage.

Consider a Depth Stop

When drilling holes to a specific depth, using a depth stop can be highly beneficial. This attachment allows you to set the desired drilling depth, preventing you from drilling too deep and potentially damaging your workpiece.

Familiarize Yourself with Speed Settings

If your drill press offers variable speed settings, take the time to familiarize yourself with each option. Different materials require different speeds to achieve optimal results. Experimentation and knowledge of these settings will enable you to handle various projects efficiently.

Always Start Slow

When initially drilling into a material, it’s wise to start with a slow speed and gradually increase the pace. This approach prevents the bit from catching or slipping and provides you with better control over the drilling process.

Ready, Set, Drill!

Now that you’re well-equipped with the knowledge of what should have occurred before using a drill press, you can confidently embark on your drilling adventures. Remember to prioritize safety, choose the appropriate drill bit and speed for your materials, and maintain your drill press regularly. With these fundamentals in place, you’ll be well on your way to achieving impressive results and expanding your skills in the realm of drilling.

Key Takeaways: What Should Have Occurred Before You Use the Drill Press?

- Wear appropriate safety gear, such as safety glasses and gloves.

- Securely fasten the workpiece to the drill press table.

- Inspect the drill press for any damage or malfunctions.

- Select the correct drill bit for the desired hole size and material.

- Adjust the drill press settings, such as speed and depth, according to the project requirements.

Frequently Asked Questions

Before using a drill press, it is important to take several precautions and ensure that the necessary steps have been followed. Here are some common questions and answers related to what should have occurred before using a drill press.

1. Why is it important to wear safety goggles when using a drill press?

Wearing safety goggles is crucial when using a drill press because it protects your eyes from flying debris, metal shavings, or wood chips that may scatter during the drilling process. Even a small piece can cause serious injury or damage to your eyesight.

Additionally, safety goggles provide a barrier against potential hazards from lubricants, coolants, or other materials used in conjunction with the drill press. Remember, it only takes a split second for an accident to happen, so always prioritize your safety.

2. What are the necessary precautions to take before using a drill press?

Prior to using a drill press, it is essential to take certain precautions to ensure your safety. First, make sure the drill press is properly secured to the workbench or floor, preventing any wobbling or movement during operation. This stability is vital for accurate and safe drilling.

Second, ensure the drill bit is securely tightened in the chuck and aligned properly before starting the press. Loose or misaligned bits can lead to accidents or damage to the workpiece. Lastly, familiarize yourself with the drill press controls, including the on/off switch and emergency stop button, and ensure they are easily accessible in case of an emergency.

3. How should you prepare the work area before using a drill press?

Preparing the work area is an important step to ensure safe and efficient operation of the drill press. Start by clearing the area of any clutter or debris that may interfere with your movement or the operation of the machine.

Next, ensure there is adequate lighting in the workspace to allow for clear visibility of the workpiece and drill press controls. Proper lighting reduces the likelihood of errors and accidents. Additionally, maintain a clean and organized work area to minimize tripping hazards and increase overall safety.

4. What safety gear should be worn when operating a drill press?

When operating a drill press, it is crucial that certain safety gear is worn to protect yourself from potential hazards. Apart from safety goggles, always wear ear protection to guard against the loud noise generated by the drill press. Prolonged exposure to loud noises can cause hearing damage.

In addition to eye and ear protection, it is advisable to wear proper attire, such as long-sleeved shirts and pants, to prevent loose clothing or jewelry from getting caught in the drill press. Non-slip footwear is also important to maintain stability while operating the machine.

5. Why is it necessary to inspect the drill press and workpiece before use?

Inspecting the drill press and workpiece before use is crucial for safe and effective drilling. Check the drill press for any loose parts, damaged cords, or worn-out components. Any issues should be addressed before proceeding with the operation to prevent accidents.

Similarly, inspect the workpiece for any defects, such as cracks or knots, that may pose a risk during drilling. Make sure the workpiece is properly secured in the vise or clamped to the table to prevent movement or shifting while drilling. Taking the time to inspect both the drill press and the workpiece helps ensure a successful and accident-free operation.

Summary

Using a drill press can be dangerous, so it’s important to take precautions. Firstly, wear safety goggles and avoid loose clothing or jewelry. Secondly, secure the workpiece firmly and adjust the table and fence accordingly. Thirdly, choose the appropriate drill bit and set the correct speed on the machine. Finally, make sure to keep your hands and fingers away from the rotating parts. Taking these steps will help keep you safe while using a drill press.

Remember, safety should always come first when operating any tool or machinery. By following these guidelines, you can minimize the risk of accidents and protect yourself from potential harm. So, next time you use a drill press, make sure to take the necessary precautions to stay safe!