Are circular saw blades hardened steel? If you’ve ever wondered about the composition of these powerful tools, you’ve come to the right place. In this article, we’ll explore whether or not circular saw blades are made of hardened steel. So, let’s dive in and find out the truth!

Now, you might be wondering, why is it important to know if circular saw blades are made of hardened steel? Well, the answer lies in their durability and performance. Hardened steel is known for its strength and resistance to wear, making it an ideal material for cutting tools like circular saw blades. But is that really the case? Let’s find out together!

So, if you’re ready to uncover the truth about circular saw blades and hardened steel, join me in the next few paragraphs. We’ll explore the characteristics of these blades, the materials they’re made of, and why it matters for your woodworking and construction projects. Get ready to become a saw blade expert!

Are Circular Saw Blades Hardened Steel? The Truth Revealed

When it comes to circular saw blades, one of the key questions that often arises is whether they are made of hardened steel. This is an important consideration as the hardness of the blade directly affects its durability, cutting performance, and resistance to wear. In this article, we will delve into the world of circular saw blades to explore the truth behind their composition and whether they are indeed made of hardened steel. Strap in as we uncover the secrets behind these essential cutting tools.

The Anatomy of Circular Saw Blades

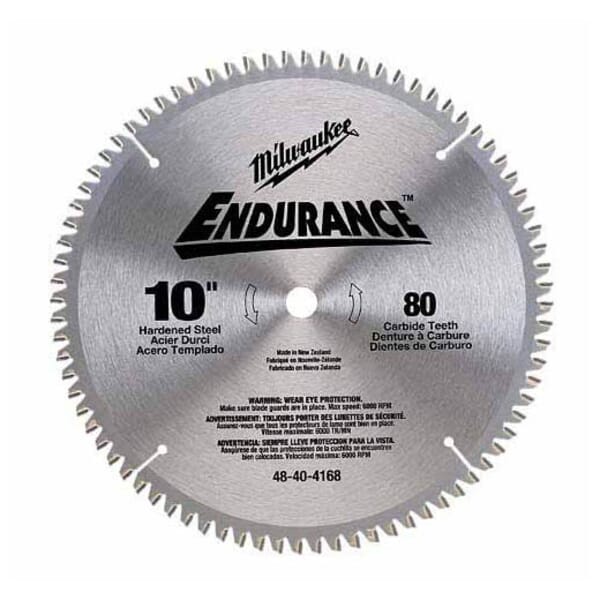

Before we delve into the hardness of circular saw blades, let us first understand their composition. Circular saw blades are typically made up of several key components, including the body, teeth, and coating. The body of the blade is usually made from high-quality steel, which provides strength and stability. It is the teeth on the outer edge of the blade that do the cutting, and these teeth can be made from a variety of materials, including high-speed steel, carbide-tipped steel, and, yes, even hardened steel. Lastly, some blades may have a coating, such as titanium or Teflon, to enhance their performance and increase their lifespan.

What is Hardened Steel?

Hardened steel refers to a type of steel that has undergone a heat treatment process called quenching and tempering. This process involves heating the steel to a specific temperature, followed by rapid cooling to harden the metal and increase its strength. Afterward, the steel is tempered by reheating to a lower temperature, which removes some of the brittleness while retaining its hardness. This process results in a highly durable and wear-resistant material, which makes hardened steel an ideal choice for tools and cutting blades.

So, are circular saw blades made of hardened steel? The answer is not as straightforward as a simple “yes” or “no.” While some circular saw blades are indeed made of hardened steel, not all of them share this distinction. The choice of blade material depends on the specific application, cutting requirements, and budget constraints. Now, let’s explore the different types of circular saw blades and the materials commonly used for their teeth.

Types of Circular Saw Blades

There are several types of circular saw blades available in the market, each designed for specific cutting tasks and materials. Let’s take a closer look at some of the most common types:

1. High-Speed Steel (HSS) Blades

High-Speed Steel blades are a popular choice for general-purpose cutting. They are made from an alloy of steel with a high concentration of tungsten and molybdenum. While HSS blades may not necessarily be made from hardened steel, they are known for their excellent cutting performance, durability, and resistance to heat. These blades work well for cutting softer materials like wood and plastic.

Pros:

- Good cutting performance

- Durable

- Good heat resistance

Cons:

- May not be as durable as carbide-tipped blades

- Not suitable for cutting harder materials like metal

2. Carbide-Tipped Blades

Carbide-tipped blades are renowned for their superior cutting performance, especially when it comes to tough materials like hardwood, metal, and laminate. These blades feature carbide teeth, which are incredibly hard and can remain sharp for a longer time compared to traditional steel blades. While the body of the blade may not be made from hardened steel, the carbide tips provide the necessary hardness and durability for efficient cutting.

Pros:

- Excellent cutting performance

- Durable and long-lasting

- Efficient for cutting hard materials

Cons:

- Higher cost compared to HSS blades

- May chip or break if used improperly or on unsuitable materials

3. Steel Blades with Hardened Teeth

Some circular saw blades feature steel bodies with hardened teeth. These blades are designed to strike a balance between cost-effectiveness and cutting performance. The hardened teeth provide increased durability and resistance to wear, while the steel body provides stability and flexibility. While not as high-performing as carbide-tipped blades, they offer a good compromise for general-purpose cutting tasks.

Pros:

- Affordable

- Good durability with hardened teeth

- Suitable for general-purpose cutting

Cons:

- Not as durable or efficient as carbide-tipped blades

- May require more frequent sharpening

Choosing the Right Circular Saw Blade

Now that we’ve explored the different types of circular saw blades and their materials, it’s essential to know how to choose the right one for your specific needs. Here are a few key factors to consider:

1. Material to be Cut

Consider the type of material you will be cutting most frequently. If you primarily work with wood, a high-speed steel blade should suffice. For cutting tougher materials like metal or laminate, carbide-tipped blades are the way to go.

2. Blade Size

Ensure that the blade size matches the arbor size of your circular saw. Using an incorrectly sized blade can result in poor cutting performance and potential safety hazards.

3. Tooth Configuration

The tooth configuration of the blade determines the type of cut it will produce. For general crosscuts and rip cuts, opt for blades with a higher tooth count. For more specialized cuts like fine woodworking or laminate, blades with specialized tooth designs may be required.

The Verdict on Circular Saw Blades

So, are circular saw blades made of hardened steel? While not all circular saw blades are made of hardened steel, there are specific types and variations that feature hardened teeth to enhance their durability and cutting performance. The choice of blade material ultimately depends on the application, cutting requirements, and budget.

When selecting a circular saw blade, it’s important to consider the material to be cut, blade size, and tooth configuration. By understanding the different types of blades and their respective strengths and weaknesses, you can make an informed decision and choose the right blade for your specific cutting needs.

Remember, no matter the material or the hardness of the blade, always prioritize safety. Wear appropriate protective gear and ensure proper use and maintenance of your circular saw and blades for optimal results and longevity.

Key Takeaways: Are Circular Saw Blades Hardened Steel?

- Circular saw blades are typically made of hardened steel.

- Hardened steel is a type of steel that has undergone a heat treatment process to increase its hardness and strength.

- Hardened steel circular saw blades are more durable and can withstand the high-speed cutting action of a circular saw.

- The hardness of a circular saw blade determines its ability to cut through different materials effectively.

- It is essential to choose the right type of circular saw blade with the appropriate hardness for the material you need to cut.

Frequently Asked Questions

When it comes to circular saw blades, many people wonder if they are made of hardened steel. Here are some common questions and answers to shed light on this topic.

1. What are circular saw blades made of?

Circular saw blades can be made of different materials depending on their intended use. Some common materials include carbide-tipped blades, high-speed steel (HSS) blades, and diamond-tipped blades. These materials are chosen for their specific cutting characteristics and durability.

Carbide-tipped blades are often preferred for their exceptional hardness, allowing them to cut through tough materials like metal and hardwood. High-speed steel blades are known for their resistance to heat, making them suitable for cutting softer materials. Diamond-tipped blades, as the name suggests, are embedded with industrial diamonds for cutting through hard materials like concrete and tile.

2. Are circular saw blades typically hardened steel?

Not all circular saw blades are made of hardened steel. While some blades may contain hardened steel components, such as the teeth, the entire blade may not be hardened. The choice of whether to use hardened steel depends on the manufacturer’s design and the intended purpose of the blade.

Blades made exclusively of hardened steel are less common in circular saws because they may be more prone to chipping or breaking when cutting harder materials. Hardened steel in combination with other materials, such as carbide or diamond, can provide the right balance of hardness and durability for various cutting tasks.

3. Do circular saw blades need to be made of hardened steel to cut through tough materials efficiently?

No, circular saw blades don’t necessarily need to be made entirely of hardened steel to cut through tough materials effectively. Blades with hardened steel teeth can offer excellent cutting performance while also maintaining durability. The hardness of the teeth helps to resist wear and maintain sharpness, ensuring efficient cutting even through hard materials.

However, the blade body itself may not need to be made of hardened steel, as long as it provides sufficient strength and stability to support the cutting process. The tooth design, material composition, and overall construction of the blade are more critical factors in determining its cutting efficiency and performance on tough materials.

4. What are the advantages of using hardened steel in circular saw blades?

Using hardened steel in circular saw blades offers several advantages. Hardened steel is highly resistant to wear, which means the teeth of the blade can maintain sharpness for a longer time. This allows for consistent cutting performance and reduces the need for frequent blade replacements.

Additionally, hardened steel blades are usually less prone to chipping or breaking compared to blades made of softer materials. The hardness of the steel can help withstand the forces applied during cutting, especially when dealing with tough materials. This ensures the longevity and durability of the blade, making it a reliable tool for various cutting applications.

5. Are there any drawbacks to using hardened steel in circular saw blades?

While hardened steel has its advantages, there are also some drawbacks to consider. One major drawback is the potential brittleness of hardened steel. Blades made entirely of hardened steel may be more susceptible to cracking or breaking when subjected to high impact or excessive force.

Another consideration is the cost. Blades made with hardened steel may be more expensive compared to those made with other materials. However, the benefits of using hardened steel, such as extended sharpness and durability, often outweigh the higher price for many professional users who rely on their circular saws for demanding cutting tasks.

Can You Harden a Saw Blade?

Summary

Circular saw blades are often made of hardened steel, which makes them strong and durable. Hardened steel is a type of steel that has been treated to increase its hardness and toughness. This makes it resistant to wear and corrosion, making circular saw blades ideal for cutting through various materials such as wood, metal, and plastic. However, it is important to note that not all circular saw blades are made of hardened steel, so it is essential to check the specifications and recommendations of the manufacturer before purchasing or using one.

In addition to being hardened, circular saw blades also have teeth that are specifically designed according to the type of cutting task. The teeth can be made of different materials, such as carbide or high-speed steel, to provide the right balance between sharpness and durability. It is important to choose the appropriate saw blade with the right tooth design for the specific cutting application to ensure efficient and precise cuts. Whether you’re a DIY enthusiast or a professional, understanding the composition and features of circular saw blades can help you make informed decisions and achieve the best results in your woodworking or construction projects.