Are you wondering what thickness of plywood to use for your exterior walls? Look no further! We’ve got you covered with all the information you need. Choosing the right plywood for your exterior walls is crucial to ensure durability and protection against the elements. In this article, we’ll explore the different thickness options available and help you make an informed decision for your project.

When it comes to building exterior walls, the thickness of the plywood plays a significant role. The right thickness provides structural stability and withstands the forces of nature. But how do you determine the ideal thickness? Don’t worry, we’ll break it down for you in simple terms. Together, we’ll explore the factors to consider and make this decision-making process a breeze.

Ready to dive in? Let’s explore the world of plywood thickness for exterior walls, discover the best options, and create a sturdy and reliable structure that stands the test of time. So, grab your hard hat and let’s get started!

What Thickness Plywood is Suitable for Exterior Walls?

Plywood is a versatile building material that can be used for various applications, including exterior walls. However, choosing the right thickness is crucial to ensure the strength, durability, and weather resistance of the walls. In this article, we will explore the factors to consider when determining the ideal thickness of plywood for exterior walls and provide you with the necessary information to make an informed decision.

The Importance of Plywood Thickness for Exterior Walls

The thickness of plywood plays a vital role in determining the structural integrity and longevity of exterior walls. It directly affects the resistance to bending, impact resistance, and weatherproofing capabilities. Generally, exterior walls require a higher thickness compared to interior walls due to exposure to external elements such as rain, wind, and temperature fluctuations. The right thickness ensures that the walls can withstand the stresses imposed by these factors and maintain their integrity over time.

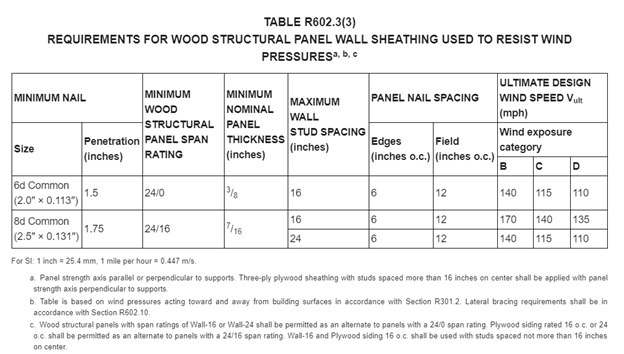

When selecting a plywood thickness for exterior walls, factors such as the location, building codes, and specific requirements of the project should be considered. Local building codes often provide guidelines for the minimum thickness required for different types of construction, and it is essential to comply with these regulations to ensure safety and structural stability.

Determining the Thickness of Plywood for Exterior Walls

To determine the appropriate plywood thickness for your exterior walls, you need to consider several factors. Here are some key considerations:

1. Building Codes: Check the local building codes to understand the minimum requirements for exterior wall construction in your area. These codes often specify the minimum thickness of plywood that should be used for various types of construction.

2. Climate and Weather Conditions: The climate of your region and the prevailing weather conditions will influence the thickness of plywood required. If you live in an area with high rainfall, extreme temperature variations, or strong winds, it is advisable to opt for thicker plywood to enhance the wall’s resistance to these elements.

3. Stud Spacing: The spacing between the wall studs also plays a role in determining the plywood thickness. If the studs are placed closer together, the walls can support thinner plywood. However, if the stud spacing is wider, thicker plywood should be used to ensure adequate rigidity and structural support.

4. Type of Exterior Finish: Consider the type of exterior finish, such as stucco, brick, or siding, that will be applied to the plywood. Some finishes require a specific thickness of plywood for proper installation and to achieve a visually appealing result. Consult with professionals or manufacturers to determine the thickness requirements for your chosen finish.

5. Structural Considerations: Lastly, consider any specific structural requirements for your project. If the exterior walls will bear a significant load, such as supporting additional floors or heavy architectural elements, thicker plywood may be necessary to provide adequate strength and stability.

By considering these factors and consulting with professionals if needed, you can determine the appropriate thickness of plywood for your exterior wall construction.

Pros and Cons of Different Plywood Thicknesses for Exterior Walls

1. 1/2-inch Plywood

1/2-inch plywood is a common choice for exterior walls due to its affordability and versatility. It offers decent structural support and is suitable for regions with moderate weather conditions. However, it may not be as durable as thicker options and may require additional precautions to protect against moisture infiltration.

Benefits of 1/2-inch Plywood for Exterior Walls:

- Cost-effective

- Can provide sufficient structural support

- Readily available

Drawbacks of 1/2-inch Plywood for Exterior Walls:

- May require additional weatherproofing measures

- Less resistant to bending and impact compared to thicker options

Example: The Benefits of 1/2-inch Plywood for Exterior Walls

1/2-inch plywood offers significant benefits for exterior wall construction. Firstly, it is a cost-effective option, making it more accessible for various construction projects. Additionally, this thickness can provide sufficient structural support to withstand typical weather conditions and maintain the integrity of the walls. Lastly, 1/2-inch plywood is readily available in most hardware stores, ensuring convenience in sourcing the material.

While 1/2-inch plywood provides several advantages, it also has some drawbacks. Due to its relatively thin profile, it may require additional weatherproofing measures to protect against moisture infiltration. Furthermore, it is less resistant to bending and impact compared to thicker plywood options, which can affect its durability and longevity in regions with harsh weather conditions or high mechanical stress.

2. 5/8-inch Plywood

5/8-inch plywood is a step up in terms of thickness and provides improved structural stability and durability compared to 1/2-inch plywood. It is commonly used in areas prone to strong winds, heavy rains, or extreme temperature fluctuations.

Benefits of 5/8-inch Plywood for Exterior Walls:

- Enhanced structural stability

- Improved resistance to bending and impact

- Suitable for regions with harsh weather conditions

Drawbacks of 5/8-inch Plywood for Exterior Walls:

- Higher cost compared to thinner options

- May require professional installation due to increased weight

Example: Enhanced Structural Stability with 5/8-inch Plywood

One of the notable benefits of 5/8-inch plywood is its enhanced structural stability. The increased thickness provides better support and rigidity for exterior walls, making them less susceptible to bending or deformation. This makes 5/8-inch plywood a suitable choice for regions with high wind loads or heavy rainfall, where the walls need to withstand external forces.

Despite its advantages, there are some drawbacks to consider. 5/8-inch plywood is relatively more expensive than thinner options, which can impact the overall project cost. Additionally, due to its increased weight, professional installation may be required to ensure proper handling and installation of the plywood sheets.

Best Practices for Installing Plywood on Exterior Walls

1. Prepare the Surface Properly

Before installing plywood on exterior walls, ensure that the surface is clean, dry, and free from any debris or contaminants. If necessary, apply a suitable water-resistant barrier or primer to enhance moisture protection.

2. Choose the Right Fasteners

Use weather-resistant fasteners such as galvanized or stainless steel nails or screws to secure the plywood to the wall studs. This helps prevent corrosion and ensures a secure and long-lasting installation.

3. Follow Proper Spacing and Overlapping Techniques

Leave a small gap between the sheets of plywood to allow for expansion and contraction. Follow recommended spacing and overlapping techniques to ensure a seamless and durable installation.

4. Apply Weatherproofing Measures

To enhance the moisture resistance of the exterior walls, consider applying weatherproofing techniques such as sealants or exterior-grade paint. This helps protect the plywood from water damage and prolongs its lifespan.

5. Seek Professional Assistance When Necessary

If you are unsure about any aspect of the installation process or have specific requirements, it is always advisable to seek professional assistance. They can provide expert advice and ensure that the plywood is installed correctly and in accordance with the relevant building codes and industry standards.

In summary, choosing the right thickness of plywood for exterior walls is essential to ensure structural integrity and long-term durability. Factors such as building codes, climate conditions, stud spacing, exterior finish, and structural requirements should be considered when making this decision. Different thicknesses, such as 1/2-inch and 5/8-inch plywood, offer their own advantages and drawbacks, and it is crucial to evaluate these in relation to your specific project needs. By following best practices for installation and seeking professional assistance when needed, you can achieve a well-built, weather-resistant, and enduring exterior wall structure.

Key Takeaways: What Thickness Plywood for Exterior Walls?

- Choosing the right plywood thickness is crucial for the strength and durability of exterior walls.

- For most exterior wall applications, a thickness of 1/2 inch or 5/8 inch is recommended.

- Thicker plywood, like 3/4 inch, may offer more rigidity and resistance to warping.

- The climate and weather conditions in your area should also be considered when selecting plywood thickness.

- Consult with a professional or follow local building codes to ensure you meet the required standards.

Frequently Asked Questions

Are you looking to find out what thickness plywood is suitable for exterior walls? Look no further! We have compiled a list of commonly asked questions on this topic to provide you with all the information you need. Read on to find answers to your queries.

Q1: What factors should I consider when determining the thickness of plywood for exterior walls?

When selecting the thickness of plywood for exterior walls, it’s important to consider a few factors. Firstly, take into account the type of wall construction you have. If you have a stud wall, you can opt for a thinner plywood sheet, around 1/2-inch thick. However, if your exterior wall is made of masonry or concrete, you may need a thicker plywood sheet, such as 3/4-inch.

Secondly, consider the climate and weather conditions your exterior walls will be exposed to. If you live in an area with high wind speeds or extreme temperature variations, a thicker plywood sheet may provide better durability and protection against the elements.

Q2: Can I use plywood with a lower thickness than recommended for exterior walls?

While it may be tempting to use plywood with a lower thickness for your exterior walls, it is not recommended. The recommended thickness is determined based on structural requirements and the ability to withstand various forces, such as wind or impact. Using thinner plywood sheets may compromise the structural integrity of your walls and reduce their overall strength and resistance.

To ensure the longevity and stability of your exterior walls, it is best to adhere to the recommended thickness guidelines provided by building codes or construction professionals.

Q3: Is there a specific plywood grade that is best for exterior walls?

Yes, there are specific plywood grades that are commonly recommended for exterior walls. Plywood with an Exterior or Exposure 1 grade is often used in exterior wall applications. These grades indicate that the plywood is suitable for exposure to moisture and can withstand the elements.

Additionally, look for plywood that is labeled as “CDX,” which signifies that it has a C-grade veneer on one side and a D-grade veneer on the other. This type of plywood provides good strength and durability for exterior wall construction.

Q4: How should I prepare the plywood before installing it on exterior walls?

Prior to installing plywood on your exterior walls, it is essential to prepare it properly. Start by inspecting the plywood sheets for any damage, such as cracks or warping. Discard any damaged sheets as they may compromise the structural integrity of your walls. Next, ensure that the plywood is adequately sealed or treated to protect it from moisture and rot.

If necessary, apply a weather-resistant finish or primer to the plywood to further enhance its durability. It is crucial to follow manufacturer recommendations for the specific type of plywood you are using to ensure proper preparation and protection.

Q5: Can I use plywood as the sole material for exterior walls?

Plywood can be used as a component of exterior walls, but it is typically not recommended to use it as the sole material. Exterior walls often require additional layers for insulation, weatherproofing, and structural support. Plywood alone may not provide adequate insulation or protection against the elements.

However, plywood can be an integral part of the exterior wall assembly, serving as a sheathing material that provides strength and support. It is commonly used in conjunction with other materials, such as insulation panels and exterior cladding, to create a durable and energy-efficient wall system.

Summary

If you’re building exterior walls, choose plywood that is at least 3/4 inch thick for durability. Thicker sheets will provide better resistance against weather and structural damage. Additionally, using pressure-treated or moisture-resistant plywood will help prevent rot and decay. Remember to seal and protect the plywood with paint or a weatherproofing treatment to extend its lifespan.

When it comes to plywood for sheathing, 1/2 inch thick sheets are commonly used. And if you’re adding siding over the plywood, 1/4 or 3/8 inch thick plywood may be suitable. Always follow local building codes and consult an expert if you have any doubts. Building sturdy and weather-resistant exterior walls will ensure the longevity and safety of your structure. Happy building!