Are you in the market for a bandsaw? Wondering what to look for in this versatile tool? Well, you’re in luck! In this article, we’ll explore the key factors to consider when buying a bandsaw, so you can make an informed decision.

Now, you might be thinking, “What exactly is a bandsaw?” A bandsaw is a power tool that features a continuous loop of teethed blade stretched between two wheels. It can cut through a wide variety of materials, including wood, metal, and plastic. But not all bandsaws are created equal, and that’s where knowing what to look for becomes crucial.

So, let’s dive right in and discuss the essential features to consider when choosing a bandsaw. From the size and power of the machine to the blade type and cutting capacity, each aspect plays a vital role in determining the bandsaw’s performance and versatility. So, buckle up and get ready to learn all about finding the perfect bandsaw for your needs!

What to Look for in a Bandsaw?

When it comes to woodworking, a bandsaw is an essential tool that can make your projects a breeze. However, with so many options available in the market, it can be overwhelming to choose the right one for your needs. In this article, we will walk you through the key factors to consider when purchasing a bandsaw, ensuring that you make an informed decision.

The Power and Size

One of the first things to consider when selecting a bandsaw is its power and size. Bandsaws come in a range of sizes, typically measured by the diameter of the wheels. The larger the wheels, the larger the cutting capacity of the machine. For general woodworking projects, a 14-inch bandsaw is ideal, as it provides enough power and flexibility. However, if you plan on working with larger pieces of wood or performing intricate cuts, you may need a larger bandsaw with more power.

The power of a bandsaw is measured by its motor size, typically indicated in horsepower (HP). For most hobbyist woodworkers, a bandsaw with a 1-2 HP motor is sufficient. However, if you’re planning to work on professional-grade projects or frequently cut through thick hardwoods, you may need a bandsaw with a more powerful motor.

Additionally, it’s crucial to consider the space you have available in your workshop. Bandsaws can be quite sizable, so ensure that you have enough room for the machine without it compromising your work area’s overall functionality.

The Cutting Depth and Throat Capacity

Another important factor to consider when choosing a bandsaw is the cutting depth and throat capacity. The cutting depth refers to the maximum thickness of wood that the bandsaw can cut through in a single pass. A deeper cutting depth allows for more versatility and the ability to work with thicker materials.

The throat capacity, on the other hand, refers to the distance between the blade and the vertical frame of the bandsaw. This measurement determines the maximum width of wood that can be cut on the bandsaw. A wider throat capacity is desirable, as it allows for more maneuverability and the ability to work with larger pieces of wood.

When considering the cutting depth and throat capacity, make sure to evaluate the types of projects you’ll be working on and choose a bandsaw that can accommodate your needs. Keep in mind that while larger cutting capacities are advantageous, they often come with a higher price tag.

Table Stability and Adjustability

When using a bandsaw, having a stable and adjustable table is crucial for accurate and precise cuts. The table should be flat, sturdy, and made of a material that allows the wood to glide smoothly across the surface. Cast iron tables are highly recommended for their durability and stability.

Additionally, the table should be adjustable both in terms of height and angle. Being able to adjust the table height allows you to align the workpiece with the blade for optimal cutting. Similarly, an adjustable angle allows you to make beveled cuts, enhancing the versatility of your bandsaw.

Consider bandsaws that offer easy-to-use adjustment mechanisms and sturdy table locks to ensure that your workpiece remains securely in place throughout the cutting process. These features can greatly contribute to the accuracy and efficiency of your woodworking projects.

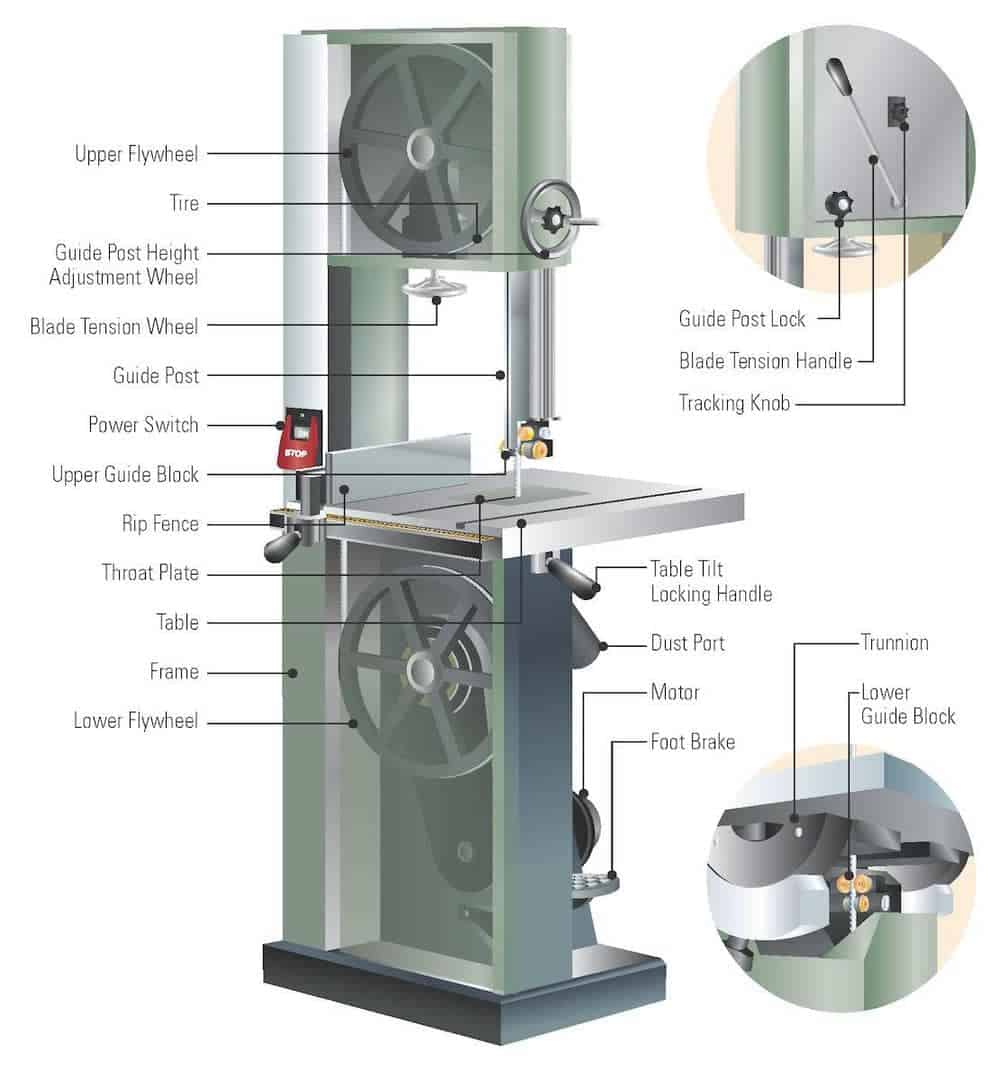

Blade Guides and Tensioning System

The blade guides and tensioning system of a bandsaw are essential components that determine the overall performance and longevity of the machine. Blade guides ensure that the blade remains stable and aligned during operation, reducing the chances of wobbling or wandering cuts.

There are two main types of blade guide systems: the traditional block-style guide and the more advanced ball-bearing guide. While both types are effective, ball-bearing guides are known for their smoother operation and require less maintenance. Additionally, consider bandsaws with adjustable blade guides, as they allow you to fine-tune the alignment according to your specific needs.

Furthermore, the tensioning system of a bandsaw is responsible for keeping the blade taut and properly adjusted for optimal cutting performance. Look for bandsaws that offer easy-to-use tensioning mechanisms, such as quick-release levers or digital tension indicators. A well-tensioned blade ensures cleaner cuts and reduces the risk of blade breakage.

Dust Collection System

Woodworking can generate a significant amount of sawdust and debris, which not only creates a messy workspace but can also be harmful to your health if inhaled. A good bandsaw should have a built-in dust collection system to effectively capture and remove the dust generated during operation.

When evaluating the dust collection system, consider the size and efficiency of the dust port. Look for bandsaws with a 2.5-inch or larger dust port, as they can easily be connected to a dust collector or shop vacuum for maximum extraction. Additionally, bandsaws with a dust collection blade guard can further improve the effectiveness of the system.

A clean and dust-free work environment not only enhances safety but also improves visibility, allowing you to focus on your projects with ease.

————————————–

Bandsaw Features to Enhance Woodworking Efficiency

When it comes to woodworking, having the right tools is essential to ensure efficiency and precision. A bandsaw, with its versatility and capabilities, can greatly enhance your woodworking projects. In this section, we will explore additional features and accessories that can take your bandsaw experience to the next level.

Fence System

A fence is an important accessory for a bandsaw as it allows you to make straight and accurate cuts. It acts as a guide, ensuring that the workpiece remains in position and parallel to the blade throughout the cutting process. Look for bandsaws that include a high-quality, adjustable fence system that can be easily positioned and locked in place.

Some fence systems also incorporate a measuring scale, which makes it easier to achieve consistent cuts. This is particularly useful when you need to make multiple identical cuts or when precision is crucial in your project.

Miter Gauge

A miter gauge is a handy accessory that allows you to make angled cuts on your bandsaw. It consists of a guide bar and a rotating plate that holds the workpiece at the desired angle. A miter gauge is particularly useful when cutting intricate designs or when creating beveled edges.

Look for bandsaws that come with a miter gauge or have a compatible miter slot to facilitate the attachment of an aftermarket miter gauge. Having the ability to make accurate angled cuts significantly expands the range of projects you can tackle with your bandsaw.

Resawing Capacity

Resawing is the process of cutting a thick piece of wood into thinner boards. This technique is widely used in woodworking and can be incredibly useful for creating veneers or obtaining thinner stock for various projects.

If you plan on resawing frequently, consider a bandsaw with a high resawing capacity. Look for bandsaws that have a tall fence and a reliable tensioning system to handle the increased strain. Additionally, a bandsaw with a wider throat capacity will provide you with more space to maneuver larger workpieces during the resawing process.

Ensuring Safety Measures with Your Bandsaw

When working with power tools like a bandsaw, safety should always be a top priority. While bandsaws are generally safe to use, there are some important safety measures that you should follow to avoid accidents and injuries. In this section, we will discuss crucial safety precautions and tips to ensure a safe and enjoyable woodworking experience.

Wear Personal Protective Equipment (PPE)

Before operating a bandsaw, make sure to wear the appropriate personal protective equipment (PPE). This includes safety glasses or goggles to protect your eyes from flying debris, hearing protection to safeguard against the loud noise generated by the machine, and a dust mask to prevent inhalation of sawdust.

Additionally, ensure that you have a good grip on the workpiece and wear sturdy gloves to protect your hands from potential cuts or injuries. Long hair should be tied back, and loose clothing should be avoided to prevent them from getting caught in the machine.

Keep the Work Area Clear

Always maintain a clean and clutter-free work area around your bandsaw. Remove any potential tripping hazards or obstacles that could interfere with your work or compromise your safety. Ensure that the floor is clear of sawdust and debris to maintain good traction and prevent slips.

Keep the bandsaw and its surrounding area well-lit to improve visibility and prevent accidental contact with the rotating blade. A well-illuminated workspace allows you to monitor the cutting process and make adjustments as needed.

Understand the Machine’s Limitations

Each bandsaw has its own limitations in terms of the maximum thickness and width of wood that it can handle. It’s important to familiarize yourself with your specific machine’s capabilities and avoid pushing it beyond its limits.

Attempting to cut oversized or excessively hard materials can put an immense strain on the blade and motor, increasing the risk of accidents or damage. Always refer to the manufacturer’s guidelines and recommendations regarding the maximum cutting capacity of your bandsaw.

Conclusion

Choosing the right bandsaw can greatly enhance your woodworking experience. By considering factors such as power, size, cutting capacity, table stability, blade guides, dust collection, and additional features, you can select a bandsaw that meets your needs and helps you achieve precise and accurate cuts.

Remember to prioritize safety by wearing appropriate protective equipment, keeping the work area clear, and understanding the machine’s limitations. With the right bandsaw and safety measures in place, you’ll be well-equipped to tackle a wide range of woodworking projects with confidence and efficiency.

Key Takeaways: What to Look for in a Bandsaw?

- Consider the size of the bandsaw – ensure it can accommodate your projects.

- Look for a powerful motor to handle various types of materials.

- Check the cutting capacity and throat depth for larger and intricate cuts.

- Choose a bandsaw with adjustable blade speed for versatility.

- Pay attention to the build quality and durability of the bandsaw.

Frequently Asked Questions

Welcome to our frequently asked questions section where we discuss what to look for when buying a bandsaw. If you’re in the market for a new bandsaw, these questions and answers will help you make an informed decision. Let’s dive in!

1. What should I consider when choosing a bandsaw?

When choosing a bandsaw, there are a few key factors to consider. Firstly, think about the size and power of the bandsaw. You’ll want to choose a model that can handle the projects you have in mind. Additionally, check the blade speed and tension as these can affect the quality of your cuts. Another important consideration is the throat size, which determines the width of cuts you can make.

Another factor to keep in mind is the build quality and durability of the bandsaw. Look for a machine made from sturdy materials that will hold up under heavy use. Finally, consider the price and value for money. While it’s important to stay within your budget, don’t compromise on quality for a lower price. With these considerations in mind, you’ll be well on your way to choosing the right bandsaw for your needs.

2. Are there any safety features I should look for?

Safety should be a top priority when working with power tools like bandsaws. Look for models that have safety features such as blade guards and emergency stop switches. These features can help prevent accidents and protect you from injury. It’s also a good idea to choose a bandsaw with a stable base or stand to minimize the risk of tipping or wobbling during operation.

Additionally, consider bandsaws with features like a blade tension release lever or quick-release mechanism. These can make blade changes easier and safer. Don’t forget to always wear appropriate protective gear such as safety glasses and hearing protection when operating a bandsaw.

3. Is it important to consider the table size of a bandsaw?

Yes, the table size of a bandsaw is an important factor to consider. A larger table provides more support for your workpiece, making it easier to control and maneuver during cuts. It allows you to work with larger materials or make intricate, detailed cuts with ease.

When choosing a bandsaw, pay attention to the dimensions of the table. Ideally, it should be spacious enough to accommodate your projects comfortably. This will ensure better accuracy and stability, resulting in cleaner cuts and less chance of accidents or mistakes.

4. What types of blades should I consider for my bandsaw?

There are different types of blades available for bandsaws, each designed for specific cutting applications. The choice of blade will depend on the material you plan to cut and the type of cuts you want to make. For example, a wide-set blade with fewer teeth is ideal for resawing, while a blade with more teeth per inch is better for finer, intricate cuts.

Consider the thickness and width of the blade as well. Thicker blades are more durable and can handle tougher materials, but they may require more power to drive. Wider blades provide more stability during cuts and are suitable for making straight cuts on larger workpieces. It’s a good idea to have a selection of blades for different purposes, allowing you to customize your cuts for each project.

5. How can I ensure proper maintenance and longevity of my bandsaw?

To ensure the longevity and performance of your bandsaw, regular maintenance is essential. Start by keeping the bandsaw clean from sawdust and debris after each use. This will prevent the buildup of gunk that can affect the smooth operation of the machine. You should also regularly check the blade for any signs of wear or damage, and replace it if necessary.

Proper blade tension is also critical for accurate cuts and reducing strain on the motor. Make sure to follow the manufacturer’s guidelines for tensioning the blade. Additionally, lubricate any moving parts as recommended by the manufacturer to reduce friction and ensure smooth operation. Finally, store your bandsaw in a clean and dry area when not in use to prevent rust and other damage. By following these maintenance practices, you can extend the lifespan of your bandsaw and keep it operating at its best.

Summary

So, when you’re looking for a bandsaw, remember these important things. First, consider the size of the bandsaw. A bigger one will give you more versatility. Second, pay attention to the power of the motor. A stronger motor means it can handle tougher materials. Third, check the blade size options. Different projects require different blade sizes. Lastly, think about the additional features you may need like a dust collection system or a miter gauge.

Now that you know what to look for, go ahead and find the perfect bandsaw for all your woodworking projects! Happy sawing!