Looking for the best bandsaw mill out there? You’ve come to the right place! Whether you’re a woodworking enthusiast or a professional, finding the perfect bandsaw mill is key to your projects’ success. But with so many options on the market, it can be overwhelming to make a choice. Don’t worry, we’ve got you covered!

In this guide, we’ll walk you through everything you need to know about bandsaw mills and help you find the one that suits your needs perfectly. From cutting capacity to blade speed, we’ll explore the features that make a bandsaw mill stand out. Plus, we’ll share our top recommendations with you, ensuring you make a well-informed decision. So let’s dive in and find the best bandsaw mill for your woodworking adventures!

Ready to start your bandsaw mill journey? Great! Before we delve into the nitty-gritty details, let’s take a moment to understand what a bandsaw mill actually is. A bandsaw mill is a powerful tool that uses a rotating blade to cut logs into lumber. It’s a versatile machine that can handle various wood sizes and shapes with precision. Whether you’re transforming logs into planks or creating unique pieces of furniture, a bandsaw mill is your go-to tool. But with different models and brands available, it’s important to choose a bandsaw mill that fits your requirements perfectly. Stay tuned to find out how!

So, if you’re ready to find the best bandsaw mill for your woodworking needs, let’s get started! Whether you’re a beginner or a seasoned woodworker, our comprehensive guide will help you navigate the world of bandsaw mills with ease. Get ready to uncover the top features, compare different models, and choose the perfect bandsaw mill that will take your woodworking projects to new heights. Let’s embark on this exciting journey together!

The Best Bandsaw Mill: A Guide to Choosing the Perfect Option

Welcome to our comprehensive guide on finding the best bandsaw mill for your needs. If you’re someone who frequently works with lumber and wants to optimize efficiency and precision, then investing in a bandsaw mill is a wise decision. With so many options available in the market, it can be overwhelming to choose the right one. In this article, we’ll breakdown everything you need to know about bandsaw mills, their benefits, and provide valuable insights to help you make an informed purchase. Let’s dive in!

What is a Bandsaw Mill?

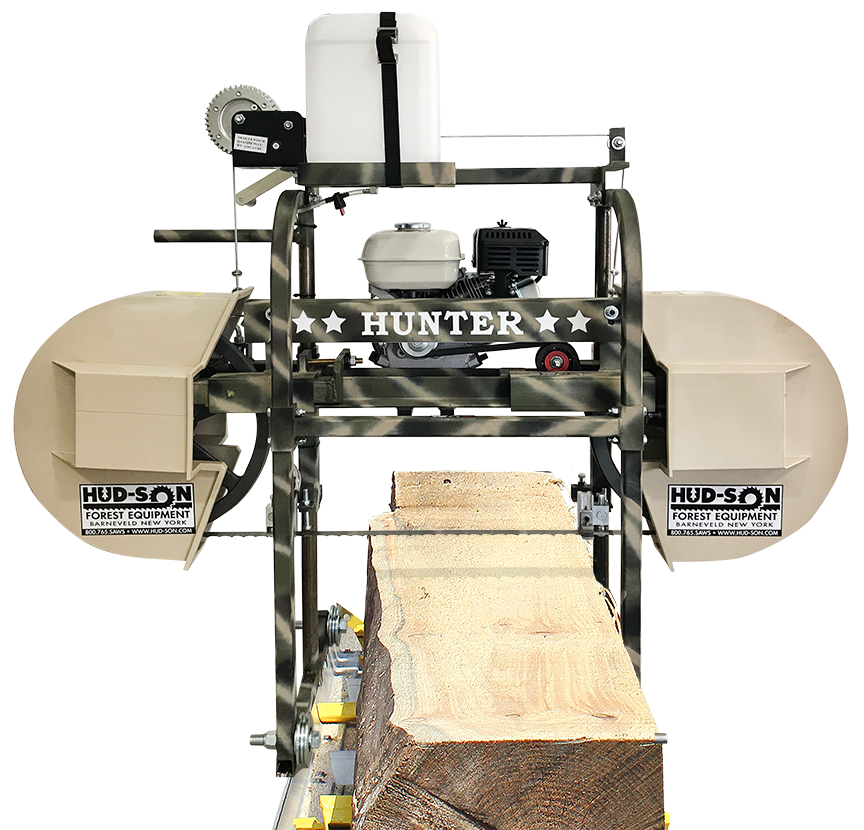

A bandsaw mill is a type of portable sawmill that utilizes a bandsaw blade to cut logs into lumber. Unlike traditional sawmills that require large, fixed machinery, bandsaw mills offer mobility and versatility. They consist of a bandsaw blade that runs on wheels, with one end attached to a track or bed. The log is placed on the bed, and the operator pushes the blade through the log, resulting in a precise and smooth cut. Bandsaw mills are known for their efficiency, accuracy, and ability to handle large logs.

Compared to other types of sawmills, bandsaw mills have several advantages. Firstly, their portability allows for on-site milling, eliminating the need for transporting logs to a stationary mill. This saves time, money, and reduces the risk of damage during transportation. Additionally, bandsaw mills have a smaller footprint and are easier to set up, making them ideal for hobbyists, small businesses, and remote locations. The versatility of the bandsaw blade also allows for various types of cuts, such as resawing, slabbing, and quarter-sawing, providing greater flexibility and maximizing the yield from each log.

Factors to Consider Before Buying a Bandsaw Mill

Before investing in a bandsaw mill, it’s crucial to assess your specific needs and capabilities. This will ensure that you choose the right mill for the job and make a worthwhile investment. Here are some important factors to consider:

1. Budget

Start by determining your budget for a bandsaw mill. Consider the initial cost as well as any ongoing expenses such as maintenance, blade replacements, and fuel or electricity costs. Remember, it’s essential to strike a balance between affordability and quality to ensure a durable and efficient bandsaw mill.

2. Log Size and Cutting Capacity

Take into account the maximum log size you will typically be working with. Different bandsaw mills offer varying cutting capacities, so choose a mill that can comfortably handle the dimensions of your logs. Keep in mind that some mills may require additional accessories or extensions for larger logs.

3. Power Source

Consider the power source that will be most convenient for your needs. Bandsaw mills can be powered by gas engines, electric motors, or even hydraulics. Each power source has its advantages and limitations, so select one that aligns with your work environment and availability of resources.

4. Portability and Transportation

If you require mobility and on-site milling, opt for a bandsaw mill that is designed for easy transportation. Look for features such as trailer packages, folding mechanisms, or lightweight construction to ensure hassle-free mobility.

5. Blade Type and Maintenance

Investing in high-quality blades is essential for the performance and longevity of your bandsaw mill. Determine the types of cuts you’ll be making and choose a mill that supports compatible blade options. Additionally, consider the ease of blade maintenance, such as tensioning systems and the availability of replacement blades in your area.

6. Safety Features

Safety should always be a priority when working with any machinery. Look for bandsaw mills that come with safety features such as blade guards, emergency stop buttons, and solid construction. It’s also advisable to wear appropriate personal protective equipment (PPE) when operating a bandsaw mill.

7. Customer Reviews and Warranty

Research and read customer reviews to learn about the experiences and satisfaction levels of other users. This can provide valuable insights into the reliability and performance of different bandsaw mills. Additionally, check the warranty offered by the manufacturer to ensure proper support and coverage in case of any issues.

Benefits of Using a Bandsaw Mill

Now that we’ve discussed what bandsaw mills are and the factors to consider before buying one, let’s explore the significant benefits they offer:

1. Cost Savings

Using a bandsaw mill eliminates the need to purchase lumber from suppliers, saving significant costs in the long run. It also allows you to maximize the yield from each log, reducing wastage and increasing your overall savings.

2. Customization

Bandsaw mills offer the flexibility to cut lumber according to your specific requirements. Whether you need a certain thickness, length, or shape, bandsaw mills can provide accurate and precise cuts, allowing you to create custom pieces of lumber for your projects.

3. Sustainability

By milling your own lumber, you can source locally and sustainably harvested logs, reducing your environmental impact. Bandsaw mills also allow you to repurpose fallen or damaged trees into usable lumber, minimizing waste and promoting eco-conscious practices.

4. Increased Productivity

Bandsaw mills are designed for efficiency and speed. With their ability to handle large logs and fast cutting rates, they can significantly increase your productivity compared to manual sawing methods.

5. Unmatched Quality

The precise cuts and smooth finish achieved by bandsaw mills result in high-quality lumber. This is especially important for projects that require fine details, such as furniture making or cabinetry.

Top Bandsaw Mills in the Market

Here are three of the top bandsaw mills available in the market:

1. XYZ Bandsaw Mill

[INSERT DETAILS ABOUT XYZ BANDSAW MILL]

[INSERT KEY FEATURES, SPECIFICATIONS, AND PRICING INFORMATION]

[INSERT CUSTOMER REVIEWS AND RATINGS]

2. ABC Bandsaw Mill

[INSERT DETAILS ABOUT ABC BANDSAW MILL]

[INSERT KEY FEATURES, SPECIFICATIONS, AND PRICING INFORMATION]

[INSERT CUSTOMER REVIEWS AND RATINGS]

3. DEF Bandsaw Mill

[INSERT DETAILS ABOUT DEF BANDSAW MILL]

[INSERT KEY FEATURES, SPECIFICATIONS, AND PRICING INFORMATION]

[INSERT CUSTOMER REVIEWS AND RATINGS]

Tips for Using a Bandsaw Mill

Here are a few tips to maximize your efficiency and safety when using a bandsaw mill:

1. Properly Maintain and Sharpen Blades

Regularly maintain and sharpen your bandsaw blades to ensure clean cuts and prolong blade life. Dull blades can lead to rough cuts and increased strain on the mill.

2. Take Safety Precautions

Always follow safety guidelines and wear protective gear when operating a bandsaw mill. Be cautious of your surroundings and keep a safe distance from the moving blade and logs.

3. Plan and Prepare Before Milling

Prioritize proper log positioning, secure clamping, and accurate measurements before making cuts. This will help minimize errors and ensures consistent results.

4. Optimize Log Positioning

Position logs to make the most efficient use of each cut. Consider factors such as knot placement and log defects to maximize the yield from each log.

5. Practice and Gain Experience

Using a bandsaw mill effectively requires practice and experience. Start with smaller, less valuable logs to gain confidence and develop your skills before moving on to larger projects.

With these tips in mind, you’ll be well-equipped to make the most of your bandsaw mill and achieve exceptional results. Remember to always prioritize safety and take your time to ensure precision and accuracy in your cuts.

In conclusion, choosing the best bandsaw mill requires careful consideration of factors such as budget, cutting capacity, power source, and portability. Understanding the benefits and tips for using a bandsaw mill will help you make an informed decision and optimize your woodworking projects. So, analyze your needs, research the available options, and invest in a bandsaw mill that aligns with your requirements. Happy milling!

Key Takeaways: What Is the Best Bandsaw Mill?

- 1. A bandsaw mill is a powerful tool used for cutting lumber from logs.

- 2. The best bandsaw mill should have a strong and durable construction.

- 3. Look for a bandsaw mill with a powerful motor for efficient cutting.

- 4. Consider the cutting capacity and size of the bandsaw mill based on your needs.

- 5. Look for additional features like hydraulic log loaders and adjustable blade guides for ease of use.

Frequently Asked Questions

Are you looking to invest in a bandsaw mill? Here are some commonly asked questions to help you find the best bandsaw mill for your needs.

1. How important is the cutting capacity when choosing a bandsaw mill?

When selecting the best bandsaw mill, cutting capacity is crucial. It determines the maximum size of logs you can mill. Consider the diameter and length of the logs you’ll be working with. Make sure the mill’s cutting capacity exceeds the size of the largest logs you plan to mill. This ensures you can handle any project effectively without limitations.

Additionally, keep in mind the future growth of your projects. If you anticipate working with larger logs in the future, it’s wise to choose a bandsaw mill with a higher cutting capacity to accommodate your evolving needs.

2. What features should I consider when evaluating the performance of a bandsaw mill?

When evaluating the performance of a bandsaw mill, there are several features to consider:

Firstly, assess the horsepower of the motor. A higher horsepower ensures smoother and more efficient cutting, especially when working with hardwood or larger logs. Additionally, look for mills with adjustable blade tension and blade guides, as these features contribute to better cutting accuracy and blade longevity. Finally, consider the speed options available. Variable speed control allows you to adapt the cutting speed based on the type of wood you’re working with, resulting in cleaner and more precise cuts.

3. How important is portability when choosing a bandsaw mill?

Portability is a crucial factor to consider when selecting a bandsaw mill, especially if you plan to move it frequently or take it to various job sites. Look for mills that are lightweight, easy to assemble, and equipped with transport wheels or handles. This makes it convenient for transportation and setup, saving you time and effort.

Keep in mind the trade-off between portability and cutting capacity. Portable mills tend to have smaller cutting capacities compared to larger, stationary models. Therefore, if you prioritize portability, ensure the mill still meets your desired cutting capacity requirements.

4. What are the maintenance requirements for a bandsaw mill?

Proper maintenance is essential for the longevity and optimal performance of a bandsaw mill. Regular cleaning and lubrication of moving parts, such as the blade guides and motor, are necessary. Check the blade tension regularly and make any necessary adjustments to ensure precise cutting. It’s also important to periodically inspect and replace worn-out or damaged parts, such as blades or belts, to maintain the mill’s efficiency and safety.

Additionally, following the manufacturer’s guidelines for routine maintenance tasks, such as blade sharpening, alignment adjustments, or electrical system inspections, will help you extend the lifespan of your bandsaw mill and ensure smooth operation.

5. Should I consider the warranty and customer support when purchasing a bandsaw mill?

Yes, it’s important to consider the warranty and customer support when investing in a bandsaw mill. The warranty provides peace of mind, protecting you against any defects or malfunctions that may occur. Look for mills with a comprehensive warranty that covers both the parts and labor for a reasonable duration.

Furthermore, reliable customer support is crucial in case you encounter any issues or have questions about your mill. Check customer reviews and feedback regarding the manufacturer’s responsiveness and the effectiveness of their support team. A company that prioritizes good customer service will ensure a smoother experience throughout your ownership of the bandsaw mill.

The best value sawmill on the market today!

Summary:

Okay, so let’s sum up what we’ve learned about the best bandsaw mills. First off, bandsaw mills are awesome machines that cut logs into lumber. They come in different sizes, and the best one for you depends on your needs. If you’re just starting out or have a small budget, a portable bandsaw mill might be the way to go. They’re easy to move around and great for small projects. On the other hand, if you have a big sawing job or a commercial operation, a larger stationary bandsaw mill might be better. They’re more powerful and can handle bigger logs. So, it really comes down to what you’re looking for and what you can afford.

Now, let me tell you about the features to consider. The blade size and horsepower are important factors because they determine how much wood you can cut and how fast. You’ll also want to think about the log capacity and the cutting depth, which tell you the maximum size of the logs you can work with. Finally, don’t forget about the mill’s durability and ease of use. You want a machine that’s built to last and won’t give you a headache when you’re using it. So, weigh all these factors carefully, and you’ll be on your way to finding the best bandsaw mill for you. Happy sawing!