Are all jigsaw blades the same? If you’re into woodworking or enjoy DIY projects, this question might have crossed your mind. Well, my friend, I’m here to shed some light on this puzzle. So, grab your favorite jigsaw and let’s dive into the world of blades together!

Imagine you’re working on a woodworking project, cutting through different materials like wood, plastic, or metal. Each material requires a specific blade to get the job done smoothly and efficiently. But here’s the thing: not all jigsaw blades are created equal. They come in various shapes, sizes, and materials, each serving a specific purpose.

So, before you embark on your next jigsaw adventure, it’s crucial to understand the differences between the blades available in the market. From T-shank to U-shank, high-speed steel to carbide-tipped, the possibilities are endless. But fear not, my curious friend, I’m here to guide you through this blade-infested maze and help you choose the perfect jigsaw blade for any cutting task that comes your way.

Whether you’re a seasoned woodworker or a budding DIY enthusiast, understanding the intricacies of jigsaw blades can elevate your projects to a whole new level. So, let’s strap on our safety goggles and unbox the mystery of jigsaw blades together. Get ready to cut through the confusion and become a blade-savvy craftsman in no time!

When it comes to jigsaw blades, not all blades are the same. Different blades have different teeth configurations, sizes, and materials, making them suitable for specific cutting tasks. Some blades are designed for wood cutting, while others are more suitable for metal or plastic. It’s essential to choose the right blade for your project to get the best results. Consider factors such as the material you’re cutting, the type of cut you need, and the blade’s TPI (teeth per inch) for optimal performance.

Are All Jigsaw Blades the Same?: A Closer Look into the World of Jigsaw Blades

When it comes to using a jigsaw, having the right blade is crucial to achieving clean and precise cuts. But with so many options available in the market, it’s important to understand if all jigsaw blades are the same. In this article, we will delve into the intricacies of jigsaw blades, exploring their differences, uses, and understanding what sets them apart from one another.

The Anatomy of a Jigsaw Blade: Understanding the Different Components

Before we dive into the variations among jigsaw blades, let’s familiarize ourselves with their anatomy. A typical jigsaw blade consists of several components, each contributing to its overall performance and functionality. These components include the shank, teeth, gullets, and body. The shank is the part of the blade that attaches to the jigsaw’s chuck, allowing the blade to be securely fastened. The teeth, positioned along the blade’s edge, are responsible for cutting through the material. The gullets, the spaces between the teeth, help remove debris and prevent the blade from clogging. Lastly, the body provides stability and support to the blade during cutting.

While these components are common to all jigsaw blades, it’s the variations within each component that make them unique. Different designs, materials, and sizes can significantly impact a blade’s performance and suitability for specific applications. Now, let’s explore these variations in more detail:

Types of Jigsaw Blades: Understanding the Different Designs

Jigsaw blades come in various designs, tailored for specific cutting tasks and materials. Let’s take a closer look at some common types:

1. T-Shank Blades

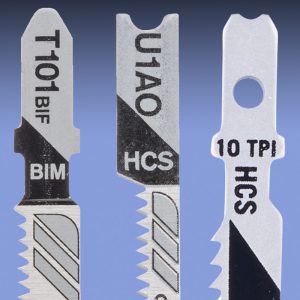

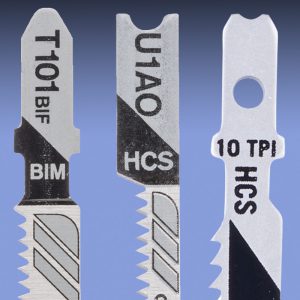

T-shank blades have a T-shaped shank that allows for quick and easy blade changes. They are the most commonly used type of jigsaw blade and are compatible with most jigsaw models. T-shank blades are available in a wide range of tooth configurations, making them versatile for different materials and cutting applications.

When selecting a T-shank blade, consider the material you’ll be working with. Blades with more teeth per inch (TPI) are suitable for cutting metal, while blades with fewer TPI are better for cutting wood. Additionally, some T-shank blades are specifically designed for cutting curves or making precise, intricate cuts.

2. U-Shank Blades

U-shank blades, also known as universal-shank blades, feature a U-shaped shank. These blades are commonly used with older jigsaw models that require a screw to fasten the blade. U-shank blades are ideal for straight-line cutting in wood, as their design offers stability and reduces blade deflection.

It’s important to note that not all jigsaws are compatible with U-shank blades. Before purchasing these blades, ensure that your jigsaw model supports them.

3. Specialty Blades

In addition to T-shank and U-shank blades, there are specialty blades designed for specific applications. These blades may have unique tooth shapes, sizes, or materials to enhance their performance in specialized cutting tasks. For example, there are blades specifically for cutting laminates, metals, plastics, or even ceramics. These specialty blades provide optimal results in their respective applications but may not be as versatile as T-shank or U-shank blades.

When considering specialty blades, it’s essential to match the blade’s design with the material you’ll be working with. This ensures better precision, efficiency, and longevity of the blade.

Choosing the Right Jigsaw Blade: Factors to Consider

Now that we understand the different types of jigsaw blades, let’s explore some important factors to consider when selecting the right blade:

1. Material

Consider the material you’ll be cutting before choosing a jigsaw blade. Different materials require different blade designs and tooth configurations. For example, cutting wood requires blades with larger, widely spaced teeth, while cutting metal requires blades with smaller, closer-spaced teeth.

2. Thickness and Hardness

The thickness and hardness of the material also play a role in selecting the right blade. Thicker and harder materials require blades with more TPI and specialized tooth configurations for efficient cutting.

3. Cutting Application

Consider the type of cut you need to make. Are you cutting curves, making straight cuts, or doing intricate detail work? Different blades are designed for specific cutting applications, so choose accordingly.

4. Price and Quality: While cost may be a factor, it’s important to prioritize quality. Investing in high-quality jigsaw blades ensures better performance, durability, and ultimately, cost-effectiveness in the long run.

By considering these factors and understanding the variations among jigsaw blades, you can select the right blade for your specific cutting needs. Remember to always refer to the manufacturer’s recommendations and guidelines for optimal performance and safety.

Additional Considerations for Jigsaw Blade Selection

Along with the factors mentioned earlier, there are a few additional considerations to keep in mind when selecting a jigsaw blade:

Teeth Per Inch (TPI)

The number of teeth per inch is a crucial aspect of jigsaw blades. A higher TPI blade is suitable for cutting delicate materials or achieving finer cuts. On the other hand, lower TPI blades are more suitable for rough cutting or faster cuts in thicker materials.

Bi-Metal Blades vs. High-Speed Steel Blades

When it comes to blade materials, there are two common options: bi-metal blades and high-speed steel blades. Bi-metal blades are made by welding together two different types of steel, combining the toughness of one steel with the cutting ability of the other. These blades are more durable and last longer than high-speed steel blades. However, high-speed steel blades are more cost-effective and are suitable for general-purpose cutting.

Blade Coatings

Some jigsaw blades come with special coatings to enhance their performance and durability. These coatings can reduce friction, increase heat resistance, and prevent corrosion. Coated blades are especially beneficial when working with materials prone to heat generation or when cutting for extended periods.

Conclusion

When it comes to jigsaw blades, they are certainly not all the same. Understanding the different types, designs, and factors to consider allows you to choose the right blade for your specific cutting needs. By selecting the appropriate blade, you can achieve cleaner cuts, increased efficiency, and better overall performance with your jigsaw. Remember to prioritize quality and refer to the manufacturer’s recommendations for optimal results. With the right blade in hand, you’ll be ready to tackle any cutting task with precision and ease.

Key Takeaways: Are All Jigsaw Blades the Same?

- Not all jigsaw blades are the same.

- Jigsaw blades vary in terms of their material and tooth design.

- Different blades are suitable for different materials and cutting tasks.

- Choosing the right jigsaw blade will result in cleaner and more efficient cuts.

- It’s important to consider the thickness and hardness of the material you’re cutting when selecting a jigsaw blade.

Frequently Asked Questions

Have you ever wondered if all jigsaw blades are the same? Let’s dive into some common questions about jigsaw blades and find out the answer.

1. How do I know which jigsaw blade to use for my project?

Choosing the right jigsaw blade depends on the material you’re cutting and the type of cut you want to achieve. Different blade types are designed for specific materials, such as wood, metal, or plastic. Some blades are optimized for straight cuts, while others are better for curves and intricate designs. It’s essential to consider the material and the cut type when selecting the appropriate blade for your project. If you’re unsure, consult the manufacturer’s recommendations or seek advice from a knowledgeable professional.

Additionally, pay attention to the teeth per inch (TPI) of the blade. Higher TPI blades are better suited for smoother and more delicate cuts, while lower TPI blades are more suitable for faster and rougher cuts. Keep in mind that using the wrong blade may result in a subpar or unsatisfactory cut.

2. Are all jigsaw blades compatible with any jigsaw?

No, not all jigsaw blades are compatible with any jigsaw. Jigsaws come in different models, and each model may require a specific type of blade. It’s vital to check the blade compatibility chart provided by your jigsaw’s manufacturer or refer to the jigsaw’s user manual. These resources will guide you on which blades are compatible with your specific jigsaw model. Using the wrong blade could lead to poor performance, damage to the jigsaw, or even personal injury, so it’s essential to use the correct blade for your specific jigsaw.

Furthermore, jigsaw blades come in various shank types, including T-shank and U-shank. Some jigsaw models only accept one shank type, while others are compatible with both. Ensure that you choose a blade with the correct shank type for your jigsaw.

3. Can I use a jigsaw blade designed for wood to cut metal?

While it may be tempting to use a wood-cutting jigsaw blade to cut metal, it is generally not recommended. Jigsaw blades designed specifically for wood are optimized for the properties of wood, such as its grain and density. When cutting metal, you need a blade that can handle the hardness and toughness of the material. Metal-cutting jigsaw blades have specialized teeth and coatings that allow them to cut through metal efficiently and with minimal vibration.

Using a wood-cutting blade on metal can lead to premature blade wear, the production of excessive heat, and potential blade breakage. It’s important to use the appropriate blade for each material to achieve the best results and prolong the life of your blades.

4. Are there any safety precautions I should take when using jigsaw blades?

Yes, there are several safety precautions you should follow when working with jigsaw blades. Always wear appropriate personal protective equipment (PPE), such as safety goggles to protect your eyes from flying debris. Additionally, wear gloves to protect your hands and a dust mask if necessary.

When changing blades, make sure the jigsaw is unplugged from the power source to prevent accidental activation. Handle blades with care to avoid cuts, and ensure they are securely fastened in the jigsaw before use. It’s important to follow the safety guidelines provided by the jigsaw’s manufacturer and exercise caution throughout the cutting process.

5. How can I extend the lifespan of my jigsaw blades?

To extend the lifespan of your jigsaw blades, there are a few steps you can take. First, make sure you’re using the appropriate blade for the material you’re cutting, as using the wrong blade can result in premature blade wear.

Additionally, cutting at the appropriate speed and using the proper cutting technique can help prolong blade life. Applying excessive force or angling the blade excessively may cause premature wear or blade damage. Lubricating the blade periodically with a lubricant specifically designed for jigsaw blades can also help reduce friction and increase cutting efficiency, leading to a longer blade lifespan.

Best Jigsaw Blade? Types of Accessories & Blades EXPLAINED

Summary

Not all jigsaw blades are the same, and choosing the right one is important for your project’s success.

If you want clean cuts, use a fine-toothed blade. For speed, a coarse tooth blade will do the trick. Different materials require different blades, so always consider what you’re cutting. Don’t forget to check the TPI (teeth per inch) for the right balance of speed and control. So, remember, picking the right jigsaw blade makes all the difference in getting the job done right!