Are you wondering how far from the edge you should screw plywood? Well, you’ve come to the right place! Let’s dive into this important question and discover the best practices for securing plywood in your projects.

When it comes to screwing plywood, the distance from the edge plays a crucial role in ensuring its strength and stability. So, how far should you go? In this article, we’ll explore the ideal placement for screws and provide you with some handy tips to make your plywood installations rock-solid.

Whether you’re a beginner or an experienced builder, understanding the correct distance to screw plywood is essential for achieving sturdy and durable results. So, let’s get started and learn the dos and don’ts of screwing plywood securely.

1. Measure the desired distance from the edge where you want to screw the plywood.

2. Mark the measured distance on the plywood using a pencil or a marker.

3. Align the edge of the plywood with the marked distance.

4. Use a drill to make a pilot hole at the marked spot.

5. Secure the plywood by inserting a screw into the pilot hole and tightening it.

By following these steps, you can accurately determine how far from the edge to screw plywood for your project.

How Far from Edge to Screw Plywood?

Plywood is a versatile material commonly used in construction and woodworking projects. When working with plywood, one important consideration is the placement of screws. The distance from the edge to screw plywood can affect the strength, stability, and overall quality of the finished product. In this article, we will explore the best practices and guidelines for screwing plywood, ensuring optimal results in your projects.

Guidelines for Screw Placement

1. Understanding the Role of Screw Placement

Proper screw placement is crucial for ensuring the structural integrity of plywood. When screws are placed too close to the edge, they can cause the plywood to split or weaken, leading to a failure in the joint or connection. Placing screws too far from the edge, on the other hand, may compromise the strength of the joint. It is important to strike the right balance to achieve the desired strength and stability.

A general rule of thumb is to keep screws at least 1 inch (2.54 cm) away from the edge of full-size plywood sheets. This distance allows the plywood to support the load effectively without causing splits or cracks. However, it’s essential to consider other factors such as the thickness of the plywood, the type of screw used, and the intended application.

2. Factors to Consider

The following factors should be taken into account when determining the distance from the edge to screw plywood:

Thickness of the Plywood:

Thicker plywood can handle screws closer to the edge compared to thinner plywood. As a general guideline, for plywood less than 3/4 inch (1.9 cm) thick, keep the screws at least 1 inch (2.54 cm) away from the edge. For thicker plywood, you may be able to reduce this distance slightly.

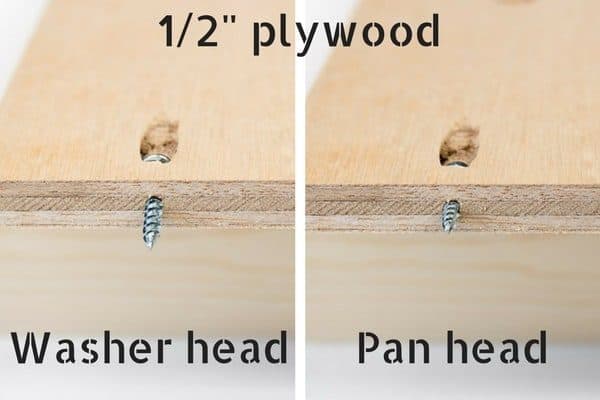

Type of Screw:

Different types of screws have varying levels of holding power and resistance to pull-out forces. For example, screws with larger threads or self-drilling screws may provide better gripping strength. This allows you to place screws closer to the edge without compromising the integrity of the plywood.

Intended Application:

Consider the intended use and load-bearing requirements of the plywood. If the plywood will bear heavy loads or experience significant stress, it’s advisable to place screws farther from the edge to distribute the load more evenly.

3. Additional Tips

Here are some additional tips to ensure proper screw placement when working with plywood:

1. Pre-drill holes: Before inserting screws, pre-drill pilot holes slightly smaller than the diameter of the screws. This helps prevent splitting and ensures a secure hold.

2. Use a countersink bit: To achieve a flush finish, use a countersink bit to create a recess for the screw heads. This allows you to fill the holes with putty or wood filler for a seamless appearance.

3. Consider edge support: If the edge of the plywood is unsupported or will be subject to stress, reinforce it with additional support, such as edge banding or blocking. This helps prevent the plywood from splitting, even if screws are placed closer to the edge.

By following these guidelines and considering the factors mentioned, you can ensure that the screws in your plywood projects are placed at the optimal distance from the edge. This will result in stronger, more durable joints, and a higher quality end product.

Common Mistakes to Avoid

1. Placing screws too close to the edge:

Placing screws too close to the edge of the plywood can lead to splitting or weakening of the material. This can affect the overall strength and stability of the joint, compromising the integrity of the project. Avoid this mistake by adhering to the recommended guidelines for screw placement.

2. Neglecting the thickness of the plywood:

The thickness of the plywood plays a significant role in determining the distance from the edge to screw. Thicker plywood can handle screws closer to the edge, while thinner plywood requires greater distance to prevent splitting. Always consider the thickness of the plywood when deciding on screw placement.

3. Failure to pre-drill pilot holes:

Pre-drilling pilot holes is essential to prevent splitting and ensure a secure hold. Neglecting this step can lead to damaged plywood and compromised screws. Take the time to pre-drill pilot holes before inserting screws, especially when working with hardwood or dense plywood.

4. Overlooking the type of screw:

Different types of screws have varying holding power and resistance to pull-out forces. Choosing the wrong screw for the job can lead to weak joints and compromised structural integrity. Consider the type of screw based on the material, load-bearing requirements, and intended use of the plywood.

5. Not providing edge support:

If the edge of the plywood will be unsupported or subject to stress, it is crucial to provide additional support. Failing to reinforce the edge can result in splitting, even if the screws are placed at the recommended distance. Use edge banding, blocking, or other suitable methods to strengthen the edge of the plywood.

6. Inconsistent screw placement:

Maintaining consistent screw placement throughout the project ensures uniform strength and aesthetics. Inconsistent spacing can lead to uneven distribution of loads and weakened joints. Use measuring tools or templates to ensure accurate and consistent screw placement.

By avoiding these common mistakes, you can achieve stronger and more reliable joints when screwing plywood.

##

Best Practices: How Far from Edge to Screw Plywood?

1. Consider the intended use:

Before screwing plywood, consider the intended use and load-bearing requirements. Heavily loaded or stressed areas may require screws to be placed farther from the edge for added stability.

TIP:

If you have specific load-bearing calculations or engineering specifications, always follow those guidelines.

2. Use high-quality screws:

Invest in high-quality screws designed for use with plywood. These screws are designed to provide optimal holding power and reduce the risk of splitting or weak joints.

3. Pre-drill pilot holes:

Pre-drilling pilot holes is essential to prevent splitting and ensure a secure hold. Be sure to use a drill bit slightly smaller than the diameter of the screw, allowing for a tight fit.

4. Use a countersink bit:

To achieve a flush finish, use a countersink bit to create a recess for the screw heads. This allows you to fill the holes with putty or wood filler for a seamless appearance.

5. Test on scrap pieces:

Before screwing plywood for your actual project, it’s always a good idea to test screw placement on scrap pieces of plywood. This allows you to adjust and fine-tune your technique to achieve the desired results.

6. Follow manufacturer guidelines:

Always refer to the manufacturer’s instructions and guidelines for the screws you are using. These guidelines may include specific recommendations for screw placement and other important considerations.

7. Seek professional advice if needed:

If you are unsure about the proper screw placement for your specific project, don’t hesitate to seek advice from professionals or consult woodworking resources. They can provide expert guidance to help you make informed decisions.

Remember, proper screw placement is critical for the strength and stability of your plywood projects. By following these best practices and considering the factors discussed earlier, you can achieve optimal results and create long-lasting, reliable structures.

Key Takeaways: How Far From Edge to Screw Plywood?

- It is recommended to screw plywood at least 3/4 inch from the edge.

- The distance from the edge to screw plywood provides better support and prevents splitting.

- Measure and mark the distance before drilling pilot holes for screws.

- Ensure proper spacing between screws for even distribution and stability.

- Using a plywood screwing jig can help maintain consistent spacing and accuracy.

Frequently Asked Questions

When it comes to screwing plywood, there are certain guidelines you should follow to ensure a secure and sturdy installation. Here are answers to some commonly asked questions on how far from the edge you should screw plywood:

1. What is the recommended distance from the edge to screw plywood?

It is generally recommended to leave a margin of at least 3/4 inch (1.9 cm) from the edge of the plywood when screwing it. This allows for better stability and reduces the risk of splitting or cracking. Leaving some space also gives the plywood room to expand and contract due to changes in temperature and humidity, preventing warping or buckling.

However, it’s important to consider the specific requirements of your project. If you are using thicker plywood or have special circumstances, it may be necessary to adjust the distance accordingly. Always consult the manufacturer’s guidelines or seek advice from a professional if you’re unsure.

2. Why is it important to leave a gap when screwing plywood near the edge?

Leaving a gap between the edge of the plywood and the screws is crucial for several reasons. First, it helps distribute the load evenly across the surface of the plywood, reducing stress concentrations that could lead to failure. By avoiding screw placement too close to the edge, you ensure that the screws are securely embedded within the material and have sufficient holding power.

Additionally, leaving a gap helps protect the plywood from splitting. When screws are driven too close to the edge, the plywood fibers can be easily damaged and may crack or splinter. By positioning the screws further from the edge, you minimize the risk of this structural integrity issue.

3. Can I screw plywood without leaving any gap from the edge?

While it may be tempting to maximize the usable space by screwing plywood without leaving any gap from the edge, it is generally not recommended. Without a gap, screws are more likely to cause the plywood to split, especially when close to the edge. This can compromise the strength and stability of the installation.

However, in certain situations where the plywood is adequately supported or reinforced, it may be possible to minimize the gap. In these cases, working with an experienced professional or following specific manufacturer guidelines is essential to ensure a safe and reliable installation.

4. Is there a difference in the recommended distance for interior and exterior plywood?

The recommended distance from the edge when screwing both interior and exterior plywood is generally the same. However, when working with exterior plywood, it’s important to consider the additional factors of weather exposure and potential moisture damage. Properly sealing the edges and using exterior-grade screws can help enhance the longevity and durability of the installation.

Keep in mind that exterior applications may have specific requirements based on the climate and conditions in your area. Consulting local building codes and guidelines or seeking advice from professionals familiar with your region is recommended to ensure a suitable installation.

5. Are there any alternatives to screws for securing plywood near the edge?

Yes, there are alternatives to screws for securing plywood near the edge. Some commonly used options include nails, staples, and adhesive. Nails are often used for thinner plywood or temporary installations, while staples provide a secure hold for upholstery or paneling applications.

Adhesive, such as construction adhesive or wood glue, can be used in addition to screws to reinforce the joint and add extra strength. However, it’s important to note that adhesive alone may not provide sufficient structural support for load-bearing applications, so it is often used in conjunction with mechanical fasteners like screws or nails.

How to screw insert into plywood perfectly

Summary

So, to sum it up: when screwing plywood, keep it at least an inch from the edge. This will prevent splits and ensure a secure attachment. Remember this rule to make your woodworking projects sturdy and long-lasting!