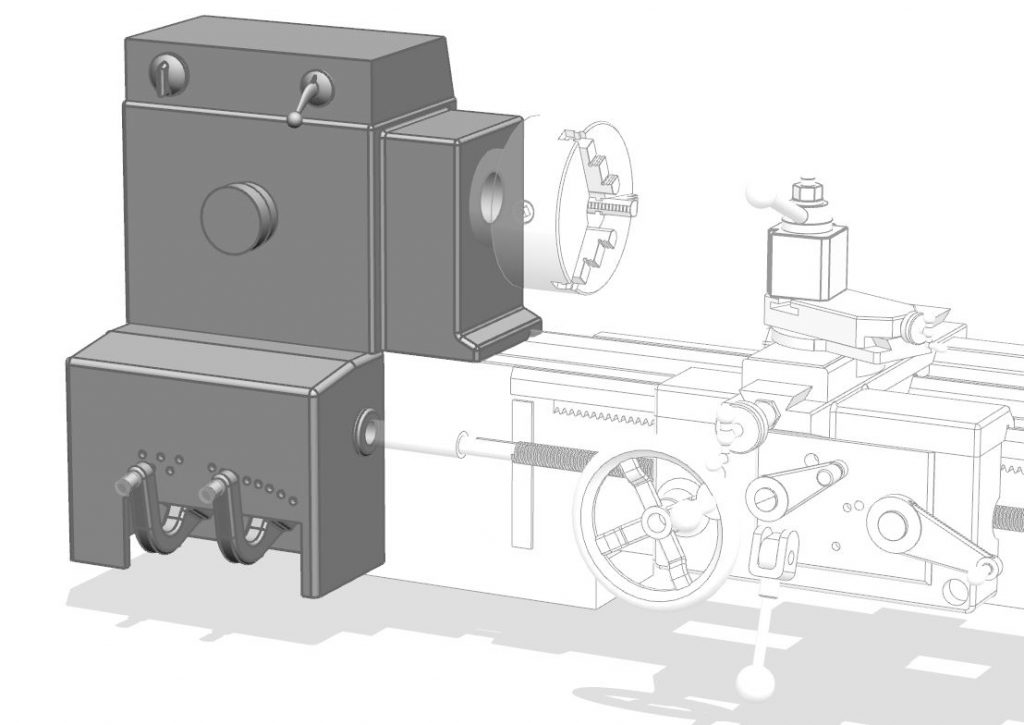

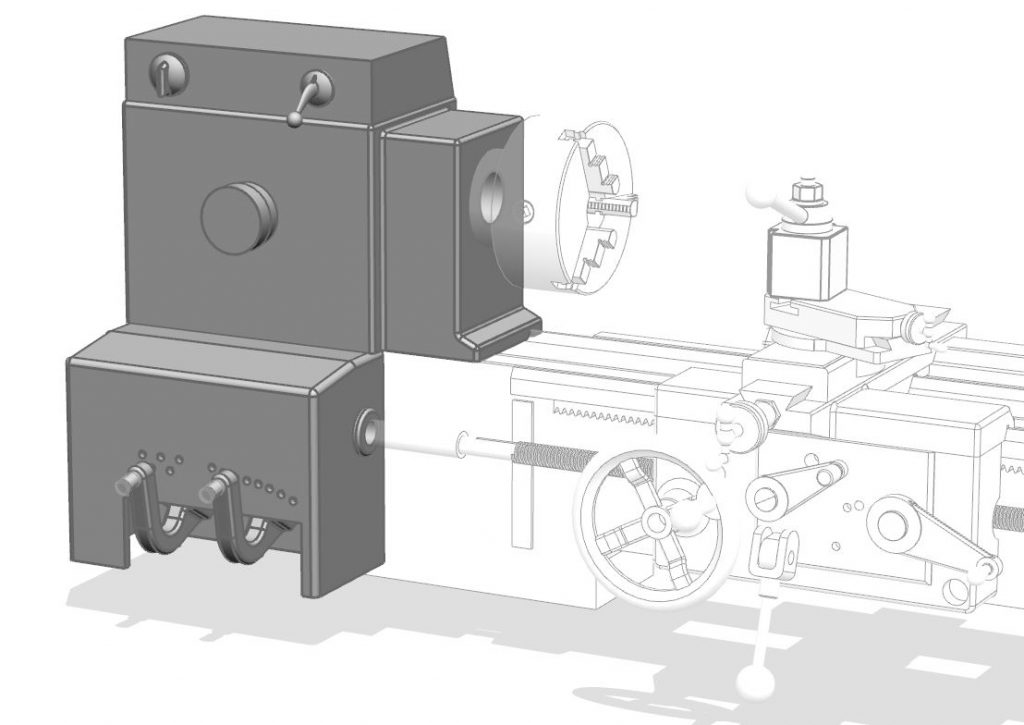

Have you ever wondered what makes a lathe machine work? Well, let’s dive into it and explore the world of lathes together! In this article, we’ll focus on one key component: the headstock. So, what is the headstock in a lathe machine?

Picture this – the headstock is like the “brain” of the lathe machine. It’s the part that holds the main spindle, which rotates the workpiece. You can think of it as the powerhouse behind the machine’s functionality.

The headstock is where the magic happens. It ensures that the workpiece is securely held in place and rotates at the desired speed. Without the headstock, a lathe machine wouldn’t be able to perform its remarkable machining operations. So, let’s delve deeper into the inner workings of the headstock and understand its vital role in the lathe machine world!

The Headstock in a Lathe Machine: Everything You Need to Know

The headstock is a crucial component in a lathe machine that plays a vital role in its functioning. It is responsible for holding and rotating the workpiece, enabling the cutting tools to shape and form the material. Understanding the headstock and its features is essential for anyone working with a lathe machine. In this article, we will delve into the details of what the headstock is, its components, and its significance in lathe machine operations.

The Functionality of the Headstock

The headstock serves as the “heart” of a lathe machine. Its primary function is to hold the workpiece securely and rotate it at various speeds. This rotation is crucial for the cutting tools to engage with the workpiece and perform turning, threading, drilling, and other operations effectively. The headstock contains a spindle, which is the component responsible for securing the workpiece. The spindle can be adjusted for different sizes and types of workpieces, allowing for versatile machining capabilities.

The headstock also houses the main motor that provides the power needed for rotating the spindle and the workpiece. The motor is typically connected to a system of gears, belts, or pulleys that transmit the rotational force to the spindle. The control system for adjusting the speed and direction of rotation is also located in or near the headstock. These features allow for precise control over the machining operations and ensure optimal performance.

Components of the Headstock

The headstock consists of several components that work together to achieve the desired results during lathe machine operations. Some of the key components include:

1. Spindle: The spindle is the main shaft that holds the workpiece and rotates it. It is typically made of hardened steel to withstand the forces and heat generated during machining.

2. Bearings: High-quality bearings support the spindle, allowing for smooth and precise rotation. These bearings reduce friction and prevent excessive wear on the spindle and other components.

3. Chuck: The chuck is the device attached to the spindle that holds the workpiece securely in place. It can be adjusted to accommodate different sizes and shapes of workpieces.

4. Motor: The motor provides power to rotate the spindle and the workpiece. It is usually an electric motor capable of delivering varying speeds based on the machining requirements.

5. Control System: The control system allows the operator to adjust the speed and direction of rotation, ensuring precise and efficient machining.

The Significance of the Headstock in Lathe Machine Operations

The headstock is an integral part of the lathe machine and has a significant impact on its overall performance. Here are some key reasons why the headstock is essential:

1. Holding and Rotating the Workpiece: The headstock securely holds and rotates the workpiece, allowing for precise machining operations. Without the headstock, it would be challenging to achieve accurate shapes and dimensions on the workpiece.

2. Speed and Power Control: The headstock’s motor and control system enable the operator to adjust the rotational speed and direction according to the specific machining requirements. This control is essential for achieving precision and desired results.

3. Versatility: The headstock’s ability to accommodate different sizes and types of workpieces makes the lathe machine highly versatile. It allows for a wide range of machining operations on various materials, making it a valuable tool in a workshop or manufacturing setting.

4. Smooth and Consistent Operation: The quality bearings and precision engineering of the headstock ensure smooth and consistent rotation, minimizing vibrations and allowing for accurate cutting and shaping of the workpiece.

5. Safety: Properly functioning headstocks with secure chuck mechanisms ensure the workpiece remains in place during machining, reducing the risk of accidents or injuries.

In conclusion, the headstock is a fundamental component of a lathe machine. It holds and rotates the workpiece, provides power and control, and enables versatile and precise machining operations. Understanding the functionality and components of the headstock is vital for utilizing a lathe machine effectively and achieving desired results in metalworking and woodworking applications.

Key Takeaways: What is Headstock in Lathe Machine?

- The headstock is an essential component of a lathe machine.

- It is located at one end of the lathe bed.

- The headstock houses the main spindle, which rotates the workpiece.

- It also contains gears for adjusting the speed of rotation.

- The headstock plays a crucial role in supporting and driving the workpiece during machining operations.

Frequently Asked Questions

When it comes to understanding a lathe machine, the headstock is a crucial component that plays a significant role. Below are some commonly asked questions about the headstock in a lathe machine:

What function does the headstock serve in a lathe machine?

The headstock is an essential part of a lathe machine as it houses the main spindle and motor. It provides rotational power to the workpiece, allowing it to rotate while undergoing turning operations. The headstock is responsible for controlling the speed and direction of rotation, ensuring precision and accuracy in the machining process.

The headstock also holds various accessories like chucks, faceplates, and centers, which are used to secure and support the workpiece. It plays a vital role in transmitting power from the motor to the workpiece, enabling the lathe machine to cut and shape materials with precision.

How does the headstock affect the performance of a lathe machine?

The headstock directly influences the performance of a lathe machine. Its design and construction determine the maximum size of workpieces that the machine can accommodate. A robust and rigid headstock enhances the stability and accuracy of the machining process, allowing for smoother cuts and finer finishes.

The headstock’s spindle speed range plays a crucial role in determining the types of materials and operations that can be performed. A lathe machine with a versatile headstock offering a wide range of speed options is more versatile, enabling the machining of different materials and achieving various surface finishes.

Can the headstock of a lathe machine be adjusted for different materials?

Yes, the headstock of a lathe machine can be adjusted to accommodate different materials. The speed of the headstock spindle can be modified to match the specific requirements of the material being machined. Higher speeds are generally used for softer materials like plastics or aluminum, while lower speeds are suitable for harder materials like steel.

Additionally, the headstock may have a gearbox or variable speed control mechanism that allows the operator to select different speed ranges. This flexibility ensures that the lathe machine can handle a wide range of materials, enabling precision machining based on the specific characteristics of each material.

Are there different types of headstocks in lathe machines?

Yes, there are different types of headstocks used in lathe machines, each with its own unique characteristics and capabilities. Some common types include stepped cone pulley headstocks, geared headstocks, and electronic variable speed headstocks.

Stepped cone pulley headstocks offer multiple speed ranges achieved by moving the belt to different pulley steps. Geared headstocks use gears to provide precise speed control and are suitable for heavy-duty operations. Electronic variable speed headstocks utilize electronic controls to adjust spindle speed smoothly and quickly, offering greater versatility and ease of use.

What maintenance is required for the headstock of a lathe machine?

The headstock of a lathe machine requires regular maintenance to ensure optimal performance. This includes keeping the spindle and bearings lubricated, checking for any signs of wear or damage, and cleaning out any accumulated debris or contaminants.

Additionally, it is essential to inspect and adjust the tension of belts if the lathe machine uses a belt-driven headstock. Regular inspection and maintenance will help prolong the lifespan of the headstock and prevent any potential issues that may affect the machine’s overall performance.

Summary

The headstock in a lathe machine is an important part that holds the workpiece. It rotates the workpiece and allows for different machining operations to be performed. The headstock has a spindle that holds the chuck, which securely grips the workpiece. This spinning motion and grip are necessary for cutting, shaping, and finishing materials like metal or wood. It’s like the power source of the lathe machine, making it possible to create various objects with precision and accuracy.

The headstock also has speed controls to adjust the rotation speed of the workpiece. This is crucial because different materials and cutting tools require different speeds for optimal results. By regulating the speed, the headstock ensures the workpiece is machined at the right rate. So, in simple terms, the headstock in a lathe machine holds and spins the workpiece, allowing for the creation of different objects through cutting and shaping, all while controlling the speed for the best outcome.