Are you curious about what lathe dogs are? Well, you’re in the right place! In this article, we’ll dive into the fascinating world of lathe dogs and uncover their purpose and importance. So, let’s get started and discover what makes lathe dogs an essential tool in machining!

Picture this: you’re working with a lathe machine, shaping and turning a piece of metal. Suddenly, you encounter a problem – the material isn’t rotating properly. That’s where lathe dogs come to the rescue! These nifty devices are like the secret agents of the machining world, ensuring that the workpiece stays securely attached and keeps spinning smoothly.

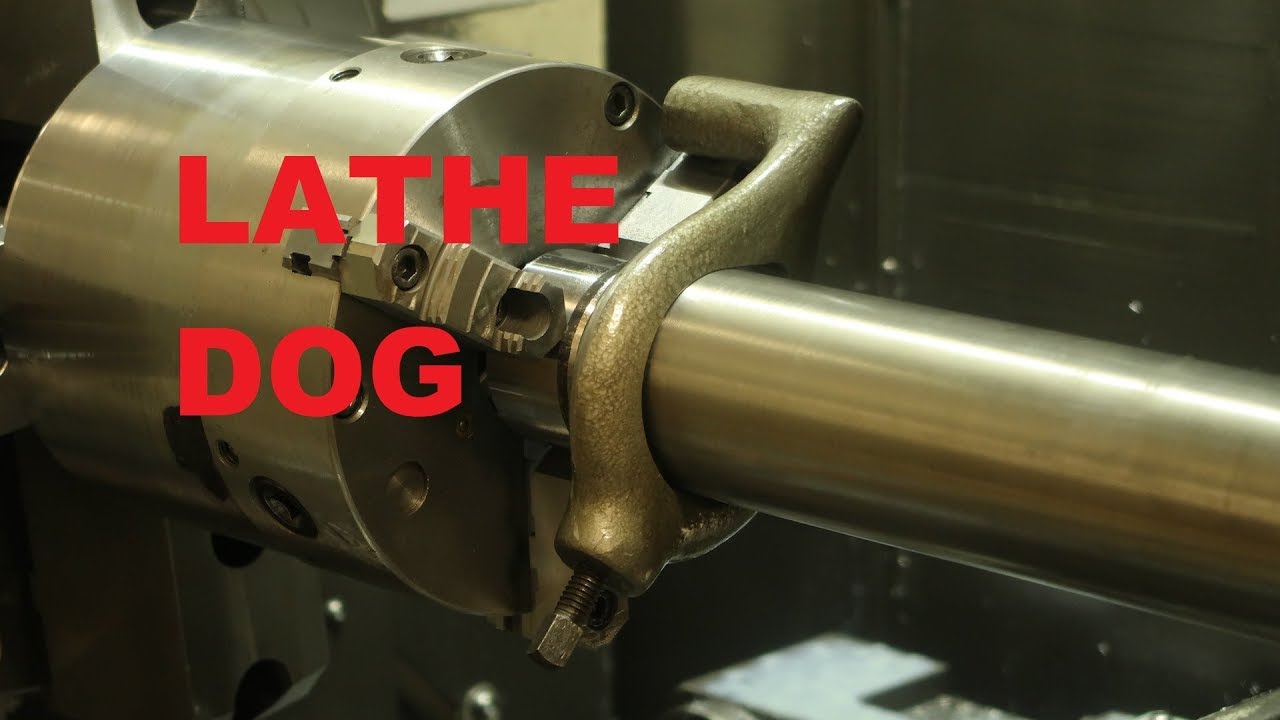

Now, you might be wondering, “How do lathe dogs work?” Well, it’s quite simple. Lathe dogs are designed to grip the workpiece tightly using their jaws or hooks. Once attached, they connect the workpiece to the rotating spindle of the lathe machine, allowing it to rotate and undergo machining operations with precision. In other words, lathe dogs play a crucial role in providing stability and control during metalworking tasks.

What Are Lathe Dogs?

Lathe dogs are an essential tool used in machining and metalworking processes, specifically with lathes. They are an important part of the lathe setup and play a crucial role in holding and rotating the workpiece during various operations. Lathe dogs are designed to grip and drive the workpiece, allowing for precision and accuracy in cutting, drilling, and shaping metal and other materials.

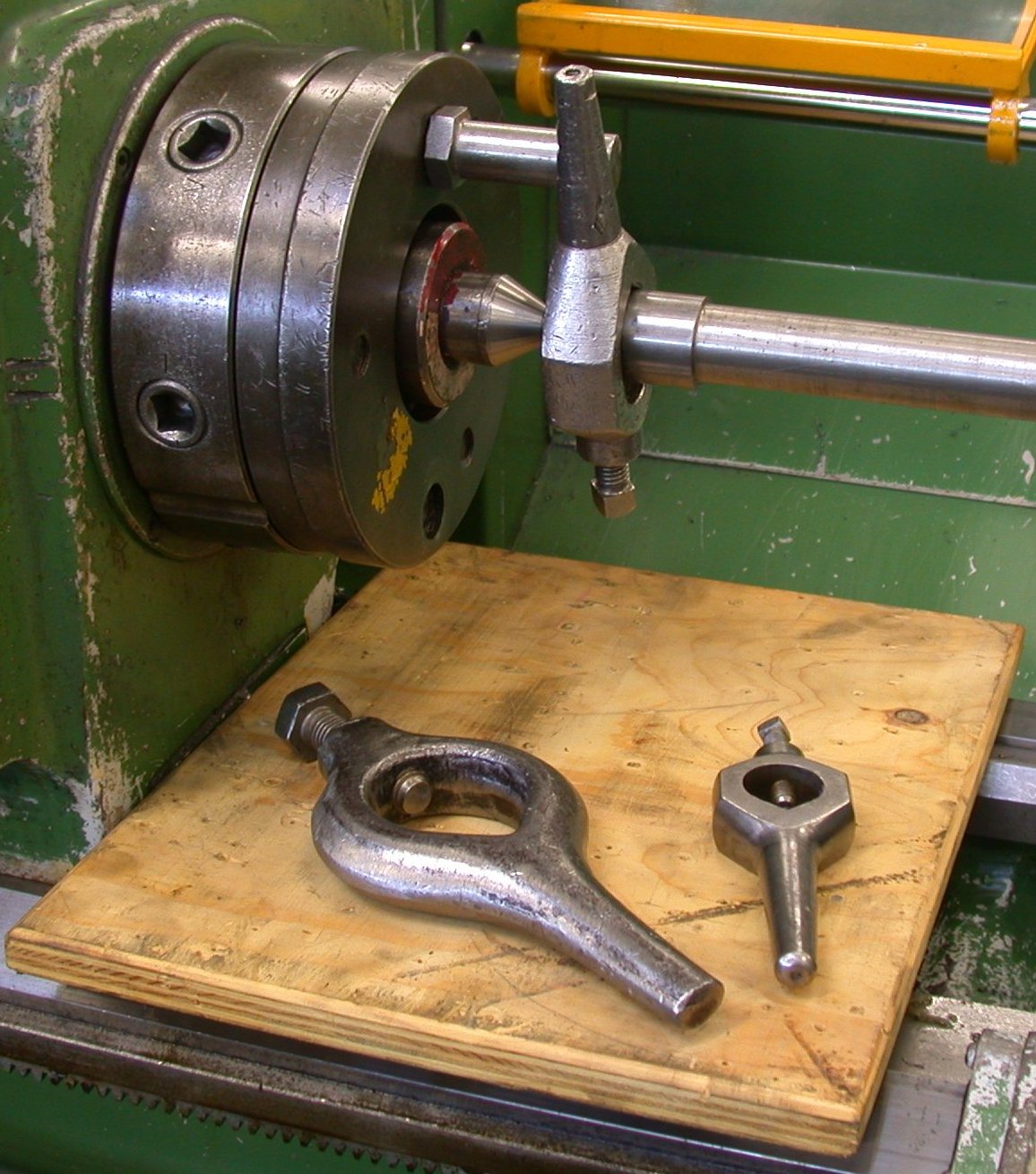

These devices are typically made of hardened steel and come in a variety of shapes and sizes, depending on the specific application and the workpiece being used. The main purpose of a lathe dog is to securely attach the workpiece to the lathe’s driving mechanism, such as the faceplate or the spindle, ensuring that it rotates at the desired speed and with minimal vibration. By providing a firm grip on the workpiece, lathe dogs allow machinists to perform various operations, including turning, facing, and chamfering, with precision and control.

Lathe dogs are commonly used in both manual and CNC (Computer Numerical Control) lathes. While the mechanisms may vary, the fundamental principle remains the same. Lathe dogs are attached to the workpiece and engage with the lathe’s driving mechanism, enabling the rotation of the material. This rotation, combined with the cutting tools, allows for the creation of precise and intricate shapes and details on the workpiece.

The Different Types of Lathe Dogs

There are several different types of lathe dogs, each designed for specific applications and workpiece shapes. The main types include:

- Standard Lathe Dogs: These are the most commonly used lathe dogs and are suitable for a wide range of workpieces. They have a simple design, with two jaws that clamp onto the workpiece, ensuring a secure grip during machining operations.

- Collar Lathe Dogs: These dogs feature an additional collar or ring that provides extra support and stability to the workpiece. Collar lathe dogs are particularly useful when dealing with long and slender workpieces, as they prevent bending and vibration during rotation.

- Half-Collar Lathe Dogs: Similar to collar lathe dogs, half-collar dogs have one side with a collar that supports the workpiece, while the other side is a standard dog. This design allows for versatility, as the collar can be positioned on either side depending on the specific requirements of the machining operation.

- Driving Plate Lathe Dogs: These dogs are commonly used when lathe work involves eccentric or irregularly shaped workpieces. The driving plate lathe dog features multiple clamping points, allowing for a secure grip on the workpiece, regardless of its shape or form.

- Angle Lathe Dogs: As the name suggests, angle lathe dogs have jaws set at an angle, making them ideal for holding workpieces with inclined surfaces. They provide a secure grip on the workpiece, allowing for precision machining at various angles.

Each type of lathe dog has its unique features and benefits, catering to specific workpiece shapes and machining requirements. Machinists must select the appropriate lathe dog based on the type of workpiece and the desired machining operation to achieve optimal results.

The Advantages of Using Lathe Dogs

Lathe dogs offer several advantages and benefits when it comes to machining operations and working with lathes:

- Secure Workholding: Lathe dogs provide a secure grip on the workpiece, preventing movement, vibration, and misalignment during machining. This ensures accurate and precise results.

- Increased Efficiency: By securely holding the workpiece, lathe dogs enable faster and more efficient machining operations. The workpiece can be rotated at high speeds without the risk of dislodging or compromising the quality of the cut.

- Versatility: The various types of lathe dogs cater to a wide range of workpiece shapes and sizes, allowing for versatility in machining operations. Machinists can choose the most suitable lathe dog for each specific job, ensuring optimal results.

- Precision and Accuracy: Lathe dogs, when used correctly, provide precise and accurate positioning of the workpiece. This is essential for achieving the desired dimensions and surface finish on the machined part.

- Reduced Risk of Damage: With a secure grip on the workpiece, lathe dogs minimize the risk of damage or accidents during machining. The workpiece remains stable and properly supported, reducing the chances of errors or mishaps.

Overall, lathe dogs play a crucial role in the machining process, ensuring the workpiece is securely held and rotated for precise cutting, shaping, and drilling. Machinists rely on these tools to achieve accurate and high-quality results in various metalworking applications.

Common Mistakes to Avoid When Using Lathe Dogs

While lathe dogs are valuable tools in machining operations, there are some common mistakes that should be avoided to ensure safe and efficient use:

- Poor Workpiece Selection: Choosing the wrong lathe dog for the workpiece can lead to instability, poor alignment, and potential damage. It is essential to carefully consider the shape, size, and material of the workpiece when selecting the appropriate lathe dog.

- Improper Installation: Incorrectly installing a lathe dog can result in the workpiece dislodging during machining, leading to accidents and damage. It is crucial to follow the manufacturer’s instructions and ensure a secure attachment of the lathe dog to the workpiece and the lathe’s driving mechanism.

- Insufficient Clamping Force: If the lathe dog is not securely clamped onto the workpiece, it may slip or rotate, affecting the precision and quality of the machining. It is important to apply sufficient clamping force to ensure a tight grip on the workpiece.

- Overloading the Lathe Dog: Exceeding the recommended weight or size limits of the lathe dog can lead to excessive stress on the tool, causing it to fail or damage the workpiece. It is essential to know and adhere to the limitations of the lathe dog to prevent accidents and equipment failure.

- Lack of Regular Maintenance: Neglecting to clean, lubricate, and inspect the lathe dog regularly can result in decreased performance, increased wear and tear, and potential safety hazards. Proper maintenance and care of the lathe dog are essential for its longevity and effectiveness.

By avoiding these common mistakes and following best practices, machinists can maximize the benefits of using lathe dogs and ensure safe and efficient machining operations.

Tips for Working with Lathe Dogs

Here are some useful tips for working with lathe dogs to achieve optimal results:

- Choose the Right Lathe Dog: Select the appropriate lathe dog based on the workpiece shape, size, and machining operation. Different lathe dogs offer specific features and benefits, so it is important to choose the one that suits the job requirements.

- Inspect and Clean the Lathe Dog: Before use, inspect the lathe dog for any signs of damage or wear. Clean it thoroughly to remove any dirt, debris, or leftover lubricants that may affect its performance.

- Properly Install the Lathe Dog: Follow the manufacturer’s recommendations for installing the lathe dog onto the workpiece and the lathe’s driving mechanism. Ensure a secure and tight fit to prevent any movement or slippage during operation.

- Apply Adequate Clamping Force: To prevent the workpiece from slipping or rotating, apply sufficient clamping force when attaching the lathe dog. Avoid excessive force that may damage the workpiece or the lathe dog.

- Maintain Regular Lubrication: Apply an appropriate lubricant to the lathe dog to reduce friction and ensure smooth rotation. Regularly lubricate the moving parts to prevent excessive wear and prolong the lifespan of the lathe dog.

- Monitor for Wear or Damage: During and after use, regularly inspect the lathe dog for any signs of wear, damage, or deformation. Replace or repair any faulty or worn-out parts to maintain optimal performance and safety.

Following these tips will help machinists achieve better results and prolong the lifespan of their lathe dogs. Proper care and usage of these tools are essential for safe and efficient machining operations.

The Future of Lathe Dogs

As technology continues to advance in the field of machining and metalworking, lathe dogs may undergo further improvements and innovations. However, the fundamental principles and functions of lathe dogs are unlikely to change significantly. These tools will continue to play a crucial role in securely holding and rotating workpieces, enabling precise and accurate machining operations.

The future may bring enhancements such as improved materials and designs, allowing for better grip, durability, and compatibility with new materials and workpiece shapes. Additionally, advancements in automation and robotics may lead to the development of self-adjusting lathe dogs or integrated systems that further streamline and optimize the machining process.

Overall, lathe dogs will remain an indispensable tool in the world of machining, providing machinists with the necessary support and precision they need to create intricate and high-quality finished products.

What are Lathe Dogs?

Lathe dogs are devices used in metalworking, particularly in turning on a lathe. They are designed to hold and rotate the workpiece securely while it is being machined.

- Lathe dogs help prevent the workpiece from sliding or rotating during the machining process.

- They have jaws that grip onto the workpiece, keeping it in place.

- There are different types of lathe dogs, including faceplate dogs and carrier dogs.

- Lathe dogs are usually made of hardened steel to withstand the high pressures and forces involved in machining.

- They are an essential tool for precision and accuracy in metalworking.

Frequently Asked Questions

Here are some common questions about lathe dogs:

1. How do lathe dogs work?

Lathe dogs are a type of gripping device that is used during turning operations on a lathe machine. They are designed to securely hold and rotate a workpiece while it is being cut and shaped. The lathe dog consists of a body with two curved jaws that can be adjusted to fit different diameters of workpieces. The body of the dog is attached to the lathe’s spindle, and the jaws grip onto the workpiece to prevent it from rotating during the cutting process.

When the lathe is in operation, the spindle rotates, and the lathe dog, with its jaws securely gripping the workpiece, rotates along with it. This synchronized rotation allows the cutting tool to remove material from the workpiece to create the desired shape or dimension. Lathe dogs are an essential tool in turning operations, as they provide the necessary stability and control for accurate and efficient cutting.

2. What are lathe dogs made of?

Lathe dogs are typically made from hardened and tempered alloy steel. This material is chosen for its strength, durability, and resistance to wear and deformation. The hardened steel allows the jaws of the lathe dog to securely grip the workpiece without slipping or distorting under the pressure of the cutting forces.

In some cases, lathe dogs may also be made from other materials, such as cast iron or brass. These materials can offer certain advantages, such as increased corrosion resistance or reduced cost, depending on the specific application. However, steel remains the most common choice for lathe dog construction due to its superior mechanical properties and suitability for high-stress operations.

3. What are the different types of lathe dogs?

There are several types of lathe dogs available, each designed for specific applications and workpiece shapes. The most common types include:

– Bent lathe dogs: These have a curved shape and are used for gripping cylindrical workpieces.

– Straight lathe dogs: These have a flat shape and are used for gripping workpieces with flat sides or surfaces.

– Face plate dogs: These are designed to attach to a faceplate and grip irregularly shaped workpieces.

– Universal lathe dogs: These can be adjusted to accommodate various workpiece shapes and sizes.

Choosing the appropriate type of lathe dog depends on the specific requirements of the turning operation and the shape of the workpiece.

4. How should lathe dogs be used safely?

When using lathe dogs, it is important to follow proper safety procedures to avoid accidents or damage to the workpiece or lathe machine. Here are some safety guidelines:

– Ensure that the lathe dog is securely attached to the lathe spindle and properly aligned with the workpiece.

– Adjust the jaws of the lathe dog to fit the diameter of the workpiece accurately.

– Use appropriate cutting tools and feeds to prevent excessive cutting forces that may cause the lathe dog to slip or fail.

– Regularly inspect the lathe dog for any signs of wear or damage, and replace it if necessary.

– Always wear proper personal protective equipment, such as safety glasses and gloves, when operating a lathe machine.

By following these safety measures, you can ensure a safe and productive turning operation using lathe dogs.

5. Are lathe dogs only used in metalworking?

While lathe dogs are commonly associated with metalworking, they can also be used in other types of materials, such as wood or plastic. The main purpose of lathe dogs is to provide a stable grip on the workpiece during turning operations. Whether it’s a metal rod, wooden dowel, or plastic cylinder, lathe dogs can be adapted to hold and rotate various types of workpieces.

However, it’s important to consider the properties and characteristics of the specific material being worked on and choose the appropriate type of lathe dog accordingly. For example, softer materials like wood or plastic may require gentler clamping forces to avoid deformation or damage to the workpiece. In any case, lathe dogs offer a versatile gripping solution across different materials and turning applications.

Summary

Lathe dogs are tools used in machining to hold and rotate workpieces on a lathe machine. They have two jaws that grip onto the workpiece, allowing it to spin. These dogs come in different sizes and styles to accommodate various types of workpieces, such as round, square, or hexagonal shapes. By securely holding the workpiece, lathe dogs enable precise shaping and cutting operations.

Lathe dogs are an essential part of the lathe machine and are commonly used in metalworking and woodworking projects. They help ensure accuracy and stability during the machining process by securely holding the workpiece in place. With their simple yet effective design, lathe dogs make it easier for machinists to perform a wide range of cutting, drilling, and shaping tasks on different materials. Whether you’re working on a small hobby project or a professional machining operation, understanding and utilizing lathe dogs can greatly enhance your accuracy and productivity.