So you’ve got a circular saw and you’re ready to tackle your next woodworking project. But wait, what’s the best circular saw blade for cutting plywood? Don’t worry, we’ve got you covered! In this article, we’ll explore the different types of circular saw blades that are perfect for cutting plywood. Whether you’re a seasoned woodworker or just starting out, this guide will help you choose the right blade for clean and precise cuts. Let’s dive in and discover the perfect blade for your plywood projects!

What Circular Saw Blade Should You Use for Cutting Plywood?

When it comes to cutting plywood with a circular saw, choosing the right blade is essential. The blade you use can have a significant impact on the quality of your cuts and the overall efficiency of your project. In this article, we will explore the different types of circular saw blades available and help you determine which one is best for cutting plywood.

Understanding Circular Saw Blades

Before diving into the specifics of choosing a circular saw blade for cutting plywood, it’s important to understand the different components of a circular saw blade. Circular saw blades are made up of three main parts: the teeth, the plate, and the gullet. The teeth are responsible for cutting through the material, while the plate supports the teeth and provides stability. The gullet, or the space between the teeth, helps with chip removal during the cutting process.

Choosing the Right Tooth Count

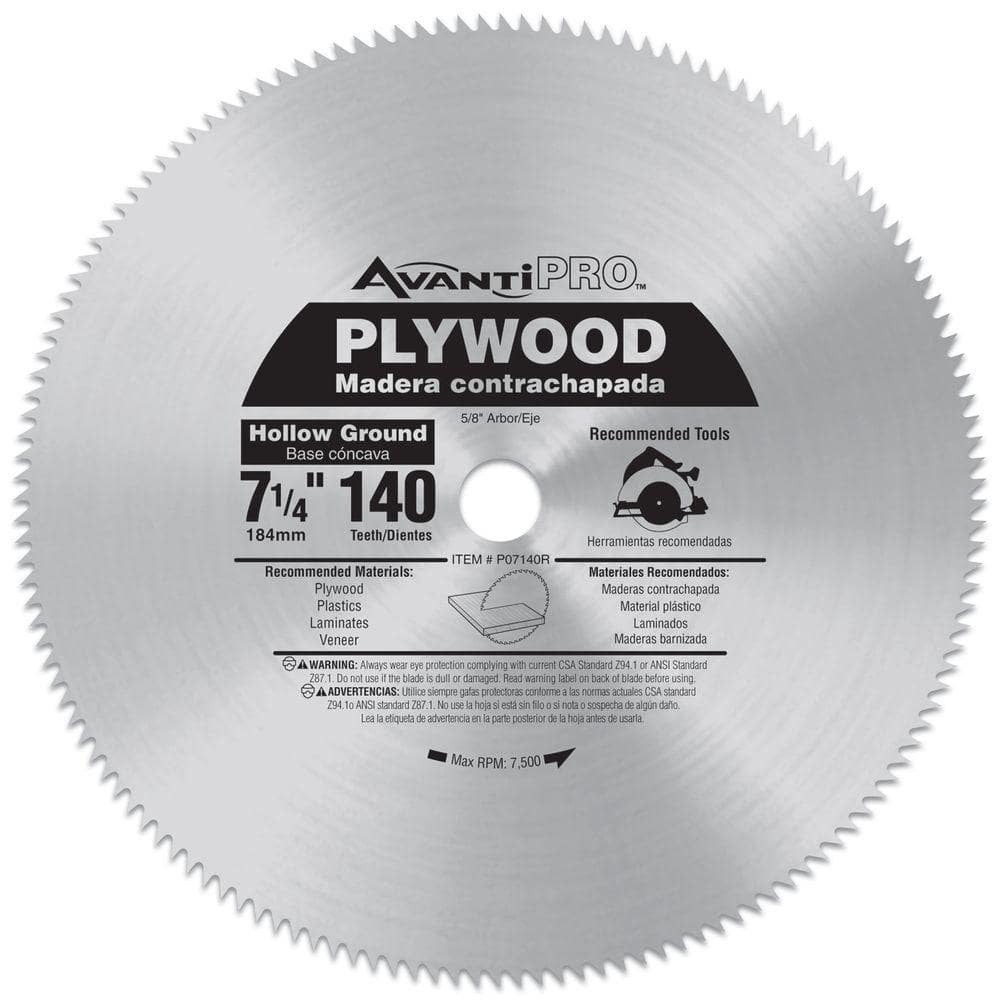

When selecting a circular saw blade for cutting plywood, one of the most important factors to consider is the tooth count. The tooth count indicates the number of teeth on the blade, and it plays a crucial role in determining the smoothness of the cut. For plywood, a higher tooth count is generally recommended. Blades with 60 or more teeth are ideal for cutting plywood as they produce cleaner cuts with minimal tear-out.

However, it’s worth noting that using a high tooth count blade may result in slower cutting speeds. If you need to make fast cuts or are working with rougher plywood, a blade with a lower tooth count, such as 40 or 50, can be used. Just keep in mind that the cut quality may not be as smooth as with a higher tooth count blade.

Consider the Blade Material

The material of the blade is another important factor to consider when choosing a circular saw blade for cutting plywood. The most common materials used for circular saw blades are carbide-tipped blades and high-speed steel (HSS) blades. Carbide-tipped blades are known for their durability and longevity, making them an excellent choice for cutting plywood. They are resistant to heat and can withstand the abrasive nature of plywood, resulting in cleaner cuts that require less effort.

HSS blades, on the other hand, are more affordable but tend to wear out faster when cutting plywood. They are better suited for softer materials and may not provide the same level of precision and cutting performance as carbide-tipped blades. If you plan to cut a substantial amount of plywood, investing in a carbide-tipped blade is a wise decision that will save you time and produce better results.

Additional Factors to Consider

While tooth count and blade material are the primary factors to consider when choosing a circular saw blade for cutting plywood, there are a few additional factors that can impact your cutting experience. The hook angle of the blade determines how aggressively it cuts through the material. For plywood, a blade with a low or negative hook angle is recommended as it reduces the risk of tear-out and produces cleaner cuts.

The kerf, or the width of the blade, can also affect the cutting process. Blades with a thinner kerf tend to remove less material and require less power to operate, resulting in more efficient cuts. However, thinner kerf blades may be more prone to deflection, especially when cutting thicker plywood. Strike a balance between kerf thickness and the material you are working with to achieve the best results.

Conclusion

When it comes to cutting plywood with a circular saw, selecting the right blade is crucial for achieving clean and precise cuts. Consider the tooth count, blade material, hook angle, and kerf thickness when choosing a circular saw blade. With the right blade, you can ensure smooth cuts and a successful woodworking project.

Key Takeaways: What Circular Saw Blade for Cutting Plywood?

- Choose a saw blade with a high tooth count, around 40 to 60 teeth, for clean and smooth cuts on plywood.

- Opt for a blade with a thin kerf, which helps reduce chip-out and tear-out on the wood surface.

- Consider a blade with carbide-tipped teeth for durability and longevity, as plywood can be tough on blades.

- Look for a blade specifically designed for crosscuts or general-purpose cutting to ensure efficient performance on plywood.

- Don’t forget to check the blade’s diameter and arbor size to ensure compatibility with your circular saw.

Frequently Asked Questions

When it comes to cutting plywood, choosing the right circular saw blade is crucial for achieving clean and precise cuts. Here are some commonly asked questions about selecting the perfect circular saw blade for cutting plywood:

1. What factors should I consider when choosing a circular saw blade for cutting plywood?

When selecting a circular saw blade for cutting plywood, there are a few key factors to consider. First, look at the size of the blade – it should be between 7 ¼ to 8 ¼ inches in diameter. Next, pay attention to the number of teeth on the blade. For smoother cuts, opt for a blade with more teeth (around 40 to 60 teeth). Lastly, consider the hook angle of the blade – a low hook angle (around 10 degrees) is ideal for cutting plywood.

By taking these factors into account, you can choose a circular saw blade that is suitable for cutting plywood and will result in clean and accurate cuts.

2. Can I use a general-purpose circular saw blade for cutting plywood?

While a general-purpose circular saw blade can cut plywood, it may not provide the best results. General-purpose blades are designed for a variety of materials, which means they may not be fine-tuned for cutting plywood specifically. Plywood is prone to splintering, so it’s recommended to use a specialized plywood-cutting blade.

A plywood-cutting blade has multiple teeth, often with a high tooth count, which helps minimize splintering and produces smoother cuts. By using a blade specifically designed for plywood, you can achieve cleaner and more precise cuts with less risk of damaging the material or encountering splinters.

3. Is it necessary to have a coating on the circular saw blade for cutting plywood?

While a coating on a circular saw blade is not necessary, it can offer certain advantages when cutting plywood. Coatings like carbide or titanium can help reduce friction and heat buildup, resulting in smoother cuts and prolonging the blade’s lifespan. Additionally, a coating can minimize the chances of the blade getting gummed up with adhesive that may be present in the plywood.

However, it’s important to note that a blade’s performance is not solely dependent on its coating. Factors such as tooth count, hook angle, and blade size play significant roles in determining the blade’s effectiveness in cutting plywood. So, while a coating can be beneficial, it isn’t the sole determining factor for choosing a circular saw blade for cutting plywood.

4. Can I use a ripping blade for cutting plywood?

Using a ripping blade for cutting plywood is not recommended. Ripping blades are designed primarily for cutting along the length of the wood grain, which can result in rougher and less precise cuts when used on plywood. Plywood has alternating grain orientations, making it prone to splintering and tear-out when cut with a ripping blade.

To achieve cleaner and smoother cuts in plywood, it’s preferable to use a cross-cutting or plywood-cutting blade, which is specifically designed to minimize splintering and produce cleaner edges. These blades have a higher tooth count and often include alternate bevel or triple chip grind features, making them more suitable for cutting plywood.

5. How can I extend the lifespan of my circular saw blade for cutting plywood?

To extend the lifespan of your circular saw blade for cutting plywood, there are a few essential steps you can take. First, ensure the blade is clean before each use – remove any debris or residue that may have accumulated. Additionally, make sure the blade is properly sharpened or replace it if it becomes dull.

Furthermore, adjust the cutting speed to match the type and thickness of plywood you’re working with. Cutting too quickly or applying excessive pressure can put unnecessary strain on the blade and lead to premature wear. Lastly, store the blade in a safe and dry place when not in use to protect it from corrosion and damage.

Summary

So, when it comes to cutting plywood with a circular saw, there are a few key things to keep in mind. Firstly, make sure you have the right blade – one with a high tooth count and fine teeth will work best. It’s also important to set the depth of the blade correctly, just deep enough to cut through the plywood but not too deep. And finally, take your time, go slow and steady to ensure a clean and precise cut. Remember these tips and you’ll be well on your way to mastering plywood cutting with a circular saw!