Ah, the frustration of a jammed hand saw! Ever wondered why it happens? Well, my young friend, today we’re going to dive into the world of hand saws and explore why they sometimes get stuck. So, if you’ve ever found yourself struggling with a stubborn saw, keep reading to uncover the secrets behind this common woodworking woe.

Now, let’s address the burning question: why do hand saws jam? When you’re sawing through wood, it’s all about the blade and the angle of attack. But sometimes, things can go awry. Whether it’s a dull blade, improper technique, or even the type of wood you’re cutting, a jammed hand saw can quickly turn your woodworking dreams into a tale of frustration.

But fear not, my curious apprentice! In this article, we’ll explore the various reasons behind hand saw jams, shed light on common mistakes to avoid, and unleash some handy tips to keep your sawing endeavors smooth and hassle-free. So, buckle up and get ready to unravel the mystery of the jammed hand saw!

Why Do Hand Saws Jam?

Hand saws are one of the most commonly used tools in woodworking and construction. However, they can sometimes become frustrating to work with when they jam. Understanding why hand saws jam and how to prevent it can save carpenters and DIY enthusiasts valuable time and effort. In this article, we will explore the main reasons behind hand saw jams and provide tips on how to avoid them.

Understanding the Mechanics of Hand Saws

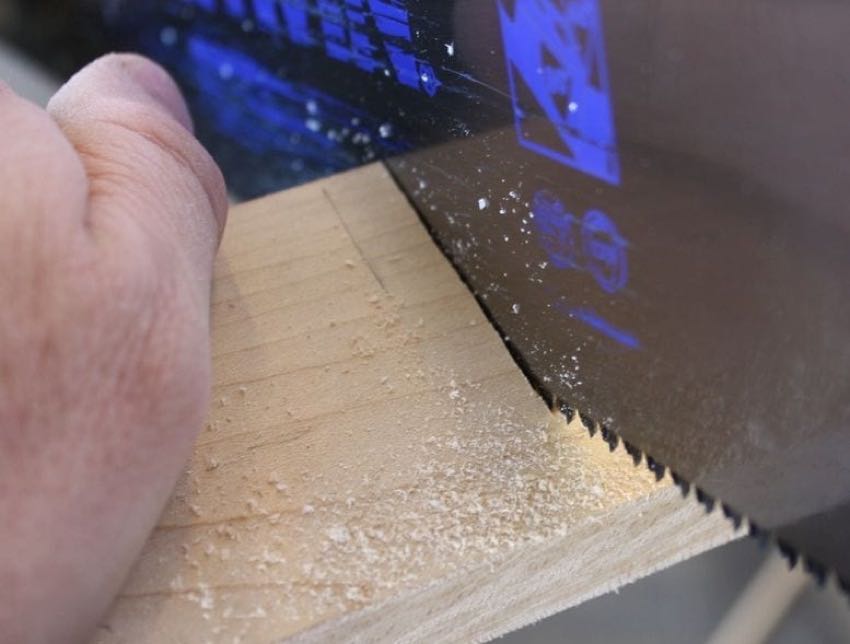

Before we delve into the reasons behind hand saw jams, it is important to have a basic understanding of how hand saws work. Hand saws consist of a toothed blade with a handle on one end. When the saw is pushed or pulled through the material being cut, the teeth of the blade remove small chips of wood or other materials. The shape and arrangement of the teeth determine the type and efficiency of the cut.

Hand saws rely on a combination of downward pressure and forward motion to cut through the material. The saw teeth need to be sharp and properly aligned for the cutting action to be smooth and efficient. When the saw teeth become dull, bent, or misaligned, the risk of jams increases significantly.

1. Dull or Damaged Teeth

One of the main reasons hand saws jam is due to dull or damaged teeth. Over time, the teeth on a saw blade can become dull from repeated use or contact with hard materials. Dull teeth struggle to remove material efficiently and can get stuck in the cut, resulting in a jam. Similarly, if the teeth are damaged, bent, or missing, they can catch on the material and cause the saw to jam.

To prevent saw jams caused by dull or damaged teeth, it is crucial to regularly sharpen or replace the blade. Sharpening the teeth involves filing each tooth individually to restore its sharpness. The frequency of sharpening will depend on the frequency of use and the type of material being cut. Regular inspection and maintenance of the hand saw will ensure smooth and uninterrupted cutting.

Additionally, avoiding contact with hard materials that can damage the teeth, such as nails or metal, can also prevent jams. If you are cutting through a material known to contain hidden nails or screws, it is advisable to use a metal detector or take necessary precautions to avoid damaging the blade.

2. Incorrect Blade Tension

Blade tension refers to the tightness with which the blade is held in the saw’s frame. Incorrect blade tension can lead to inconsistent cutting performance and contribute to saw jams. When the blade tension is too loose, the blade can wander off the desired cutting line or bow, causing it to bind and jam. On the other hand, if the tension is too tight, it can put excessive strain on the blade, leading to premature wear and potential breakage.

To ensure optimal blade tension and reduce the risk of jams, it is important to follow the manufacturer’s recommendations. Most hand saws have an adjustment mechanism that allows users to tighten or loosen the blade tension. Regularly checking the tension and making necessary adjustments will help maintain the saw’s performance and prevent jams.

3. Incorrect Cutting Technique

Another common cause of hand saw jams is an incorrect cutting technique. The way you hold and guide the saw through the material can significantly impact the smoothness of the cut. If you apply too much downward pressure or try to force the saw through the material too quickly, the blade can bind and get stuck.

It is essential to use a controlled and steady motion when cutting with a hand saw. Apply enough pressure to maintain contact between the teeth and the material but avoid exerting excessive force. Let the saw’s teeth do the work, allowing them to remove the material gradually. Taking your time and using smooth, even strokes will help prevent jams and ensure a clean cut.

Additionally, using a saw with the appropriate tooth count and type for the material being cut can also minimize the risk of jams. Different saws are designed for specific applications, such as crosscutting or ripping. Using the right saw for the job will improve efficiency and reduce the likelihood of jams.

4. Clogging of Sawdust

Sawdust accumulation can also contribute to hand saw jams. Sawdust can get trapped between the teeth and prevent them from effectively cutting through the material. This is particularly common when cutting soft or resinous woods that produce a high volume of fine particles.

To prevent sawdust buildup, it is advisable to periodically clear the teeth and the cut line. Using a brush or compressed air can help dislodge the sawdust, allowing the teeth to continue cutting smoothly. Additionally, saws with anti-clogging features, such as wider gullets between the teeth or specialized coatings, can help prevent or reduce the occurrence of jams caused by sawdust.

5. Improper Saw Maintenance

Proper maintenance of hand saws plays a crucial role in preventing jams. Neglecting to clean, lubricate, or protect the saw can cause various issues that lead to jams. Rust, for example, can develop on the blade and hinder the smooth movement of the saw, resulting in jams. Over time, the handle of the saw can become loose or develop cracks, affecting the stability and control.

Regular cleaning and lubrication of the saw will help prevent rust and ensure smooth operation. Cleaning involves removing sawdust, dirt, and other debris from the blade and handle. Lubrication can be done by applying a thin layer of oil or wax to the blade, reducing friction and improving cutting performance. Additionally, inspecting the handle and tightening any loose parts will help maintain control and prevent accidents.

6. Inaccurate Cutting Line

An inaccurate cutting line can also contribute to hand saw jams. If the line is not marked precisely or is poorly aligned with the teeth of the saw, it can cause the blade to deviate from the intended path and bind in the material.

To ensure accurate cuts and reduce the risk of jams, it is vital to take the time to mark the cutting line correctly. Use a sharp pencil or marking knife to create a clear and precise line that aligns with the teeth of the saw. Taking extra care during the marking process will help guide the saw accurately and prevent deviations that can lead to jams.

Proper Hand Saw Maintenance and Safe Handling

Now that we have explored the main causes of hand saw jams, let us discuss the importance of proper hand saw maintenance and safe handling. Regularly inspecting the saw, sharpening the teeth, and ensuring the blade tension is optimal will significantly reduce the risk of jams. Additionally, using the proper cutting techniques, clearing sawdust buildup, and marking accurate cutting lines are essential to maintaining a smooth and efficient cutting process.

Remember to always prioritize safety when handling hand saws. Wear appropriate personal protective equipment, such as safety glasses and gloves, to protect against potential injuries. Ensure a stable cutting surface and maintain a firm grip on the saw to prevent accidents.

By understanding the reasons behind hand saw jams and implementing the necessary preventive measures, you can enjoy a frustration-free woodworking or construction experience. Regular maintenance and safe handling will not only improve the performance of your hand saw but also extend its lifespan. Happy sawing!

Key Takeaways: Why Do Hand Saws Jam?

- Hand saws can jam when the saw teeth get stuck in the material being cut.

- Using excessive force or sawing at the wrong angle can cause a hand saw to jam.

- A dull or improperly maintained saw blade can also lead to jamming.

- Uneven pressure during cutting can cause the saw to bind and jam.

- Proper technique, regular maintenance, and using the right type of saw for the job can help avoid saw jams.

Frequently Asked Questions

In this section, we will address some common questions about why hand saws jam and how to prevent it. Read on to find out more!

1. What are the main reasons why hand saws jam?

Hand saws can jam for several reasons. One common cause is using excessive force while cutting, which can cause the saw to bind in the material. Another reason is using a dull blade, as it may struggle to cut through the material and get stuck. Additionally, improper sawing technique, such as applying too much side pressure, can lead to jams. Understanding these causes can help you prevent jams and ensure smooth cutting.

Furthermore, the type of material being cut can also contribute to saw jamming. For example, sawing through wet or resinous wood can cause the blade to gum up, leading to a jam. Lastly, using a hand saw with a blade that is not suitable for the material being cut, such as using a crosscut saw on rip cuts, can also result in jams.

2. How can I prevent hand saws from jamming?

Preventing hand saws from jamming starts with using the right saw for the job. Make sure you choose a saw with the appropriate blade type for the material you are cutting. Using a sharp blade is also crucial, as a dull blade is more likely to jam. Regularly inspect your hand saw and sharpen or replace the blade when necessary.

In addition, using the correct sawing technique can help prevent jams. Avoid putting excessive pressure on the saw and let the tool do the work. Maintain a steady, controlled cutting motion and avoid applying side pressure. Keeping the saw clean, especially if you’re working with resinous or wet material, can also reduce the chances of jams.

3. Can using a lubricant help prevent hand saw jams?

Yes, using a lubricant can be helpful in preventing hand saw jams. Applying a lubricant, such as a silicone spray or a wax stick, to the blade can reduce friction and make the cutting process smoother. It can also help prevent the blade from getting gummed up when cutting through resinous or wet materials.

However, it’s important to note that not all types of lubricants are suitable for use with hand saws. Avoid using lubricants that can damage the wood or interfere with the cutting process. It’s best to use lubricants specifically designed for hand saws or consult the manufacturer’s recommendations.

4. Is there a way to fix a jammed hand saw?

If your hand saw does get jammed, there are a few steps you can take to try and fix it. First, stop the cutting motion and carefully remove the saw from the material. Inspect the blade and remove any debris or obstructions that may be causing the jam. If the blade is dull or damaged, consider sharpening or replacing it before continuing.

Once you’ve cleared the blade and ensured it’s in good condition, you can slowly resume cutting, taking care to use proper technique and avoid applying excessive force. If the saw continues to jam or encounters resistance, it may be best to seek professional assistance, as there may be underlying issues with the saw or the material being cut.

5. What are some signs that my hand saw is about to jam?

There are a few signs to look out for that may indicate your hand saw is about to jam. If you notice the saw blade binding or getting stuck in the material during cutting, it’s a clear indication of a potential jam. You may also observe the saw struggling to make progress, requiring more effort to continue cutting.

In some cases, you may hear a change in the sound produced by the saw, such as a grinding or screeching noise. This can be an early warning sign that the saw is encountering resistance and may jam if not addressed. If you notice any of these signs, it’s important to stop cutting, assess the situation, and take appropriate measures to prevent a full-blown jam.

Cheap Saw Vs Expensive Saw What Is The Difference

Summary

Sometimes hand saws get stuck because the teeth get clogged or the blade is bent. It’s important to clean and maintain your saw to prevent jams. When using a saw, remember to go slowly and let the saw do the work for you.

If your saw does get jammed, stop and assess the situation. Don’t force the saw as this can lead to accidents. Instead, try removing any debris or straightening the blade. With proper care and caution, you can avoid jams and keep your hand saw working smoothly for a long time.