Do you ever wonder how things get their names? Well, let’s dive into the fascinating world of machinery and explore the origins of the term “engine lathe.”

First things first, what comes to mind when you hear the word “engine”? Maybe you’re thinking of a powerful machine that makes things go, like a car engine. And what about “lathe”? Well, that’s a tool used to shape and cut materials, often in a circular motion. So, when you combine the two, “engine lathe” refers to a type of lathe that is powered by an engine.

But why is it called an “engine” lathe? To find out, we need to take a journey back in time. In the early days of manufacturing, lathes were powered by humans or animals. Just imagine how tiring that must have been! Then came the Industrial Revolution, and with it, the invention of steam engines. These powerful machines could generate the energy needed to turn lathes, making the manufacturing process much more efficient. And that’s how the term “engine lathe” came to be.

So, the next time you see a lathe at work, remember that its name comes from the mighty engines that power it. It’s just one example of how the evolution of machinery has shaped our language and the way we describe things.

Why is it Called an Engine Lathe?

Engine lathe is a term frequently used in the machining industry, but have you ever wondered why it’s called an engine lathe? In this article, we will explore the origins and reasoning behind the name. We’ll delve into the history of the machine and its significance in manufacturing processes. So, let’s uncover the fascinating story behind the name “engine lathe.”

The Evolution of Lathes

The lathe has been around for centuries and has played a crucial role in shaping various materials. In ancient times, lathes were operated manually, using a bow or a rope to rotate the workpiece. Over time, advancements in technology led to the invention of more sophisticated lathes that employed different power sources.

During the Industrial Revolution, steam engines became increasingly prevalent. These engines provided a reliable and powerful source of energy to drive different machines, including lathes. The term “engine” was commonly associated with steam engines, and it eventually became synonymous with the power source used to drive lathes. Hence, the name “engine lathe” emerged.

Today, engine lathes are typically powered by electricity, but the term has stuck, representing the long history and evolution of this essential machine tool.

The Versatility of Engine Lathes

Engine lathes have earned their place as a versatile and indispensable tool in the machining industry. They are capable of performing a wide range of operations, such as turning, facing, drilling, and threading. This versatility makes them suitable for various applications, from small-scale hobby projects to large-scale industrial manufacturing.

Engine lathes are known for their robust construction, precision, and stability, allowing for accurate and high-quality machining. They can handle both ferrous and non-ferrous materials, making them suitable for a diverse range of projects.

Furthermore, engine lathes can be equipped with various attachments and accessories to enhance their functionality. These include taper attachments, steady rests, collet chucks, and digital readout systems, expanding the capabilities of the machine even further.

Benefits of Engine Lathes

Engine lathes offer several benefits that contribute to their widespread popularity and continued use in the machining industry. Here are some of the key advantages:

1. Versatility: Engine lathes can perform a multitude of operations, eliminating the need for multiple specialized machines.

2. Precision: These lathes are renowned for their accuracy and ability to produce intricate shapes and finishes.

3. Durability: Engine lathes are built to withstand rigorous use and maintain their performance over time.

4. Adaptability: With the wide range of attachments available, these lathes can be customized to suit specific machining requirements.

5. Cost-effectiveness: Engine lathes offer a cost-effective solution for various machining needs, especially for small to medium-sized businesses.

Conclusion

The term “engine lathe” has a rich history and is deeply ingrained in the language of the machining industry. It originated from the use of steam engines to power lathes during the Industrial Revolution. Today, engine lathes continue to be widely used and valued for their versatility, precision, and durability. Whether you’re a hobbyist or a professional machinist, understanding the significance of this machine’s name adds to the appreciation of its timeless importance in manufacturing processes.

Key Takeaways: Why is it called an engine lathe?

- An engine lathe is called so because it was initially powered by a steam engine.

- The steam engine provided the rotational power needed to turn the workpiece on the lathe.

- As technology advanced, engine lathes started to be powered by electricity instead of steam engines.

- Despite the change in power source, the name “engine lathe” stuck to describe this type of lathe.

- Engine lathes are versatile machines used for shaping and machining various materials.

Frequently Asked Questions

In this section, we will answer some common questions about why it is called an engine lathe and provide some insights into its origins and functions.

What is an engine lathe used for?

An engine lathe is a machine tool used for shaping and machining cylindrical workpieces. It is commonly used in metalworking industries to perform various operations such as cutting, drilling, turning, and threading. The name “engine” is derived from the early use of these lathes for creating parts for steam engines, but today, engine lathes are used in a wide range of applications across different industries, including automotive, aerospace, and manufacturing.

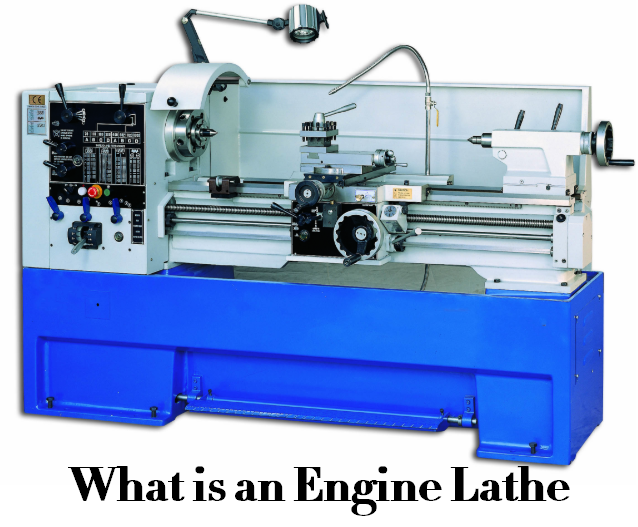

The design of an engine lathe allows for precise and accurate machining of cylindrical shapes. It consists of a spindle that rotates the workpiece, a carriage that holds the cutting tool, and various controls to regulate the speed and movement. With its versatility and capability to produce intricate parts, an engine lathe remains an essential tool in many workshops and manufacturing facilities.

How did the engine lathe get its name?

The term “engine” in engine lathe dates back to the early days of the Industrial Revolution when lathes were being used to manufacture parts for steam engines. The early engine lathes were specifically designed to produce the precision components needed for engine construction. Over time, the term stuck and became the commonly used name for this type of lathe. Despite the evolution of technology and manufacturing processes, the name “engine lathe” has endured and is still used to refer to this type of machine tool today.

It is important to note that the term “engine” in engine lathe does not refer to an internal combustion engine or any specific type of engine. Instead, it is a historical reference to the origins of these lathes and their association with early engine manufacturing.

Are engine lathes still used today?

Yes, engine lathes are still widely used today. Despite advancements in technology and the introduction of computer-controlled machines, engine lathes remain an important tool in many industries. They are particularly valued for their versatility, durability, and precision. Engine lathes are used in various applications, including metalworking, woodworking, and even in the production of musical instruments. While their design and features may have evolved over time, the basic principles of an engine lathe have remained the same, allowing them to continue playing a crucial role in manufacturing and fabrication processes.

Engine lathes are favored for their ability to accurately shape and machine cylindrical workpieces. Additionally, their manual operation provides users with a hands-on experience and allows for greater control over the machining process. This level of precision and control, combined with their durability and reliability, makes engine lathes a trusted choice for many workshops and industries.

What are the advantages of using an engine lathe?

An engine lathe offers several advantages that make it a preferred choice for many applications. Firstly, it provides a high level of precision and accuracy, allowing for the creation of complex and detailed parts. This precision is achieved through the control of cutting tools, speed, and feed rates, resulting in finished products that meet tight tolerances and quality standards. Additionally, the design of an engine lathe allows for the use of various cutting tools and attachments, further enhancing its versatility in machining different materials and shapes.

Another advantage of using an engine lathe is its dependability. Engine lathes are known for their durability and robust construction, making them reliable machines that can withstand heavy usage and provide consistent performance over a long period of time. These lathes are also relatively easier to operate and maintain compared to more advanced computer-controlled machines, making them accessible to a wider range of users. Lastly, engine lathes can be cost-effective, especially for small to medium-sized businesses or for those who don’t require the advanced capabilities of computer-controlled machines.

What are the key components of an engine lathe?

An engine lathe consists of several key components that collectively enable its functionality. The main components include the spindle, carriage, tailstock, and cutting tool. The spindle is the rotating part of the lathe that holds and rotates the workpiece. It is driven either manually or through a motor. The carriage is responsible for holding and moving the cutting tool, allowing it to make precise cuts and shape the workpiece. It is controlled by various mechanisms, including handwheels and levers, enabling the user to control the position and movement of the cutting tool.

The tailstock is located at the opposite end of the lathe from the spindle. It provides support to the workpiece and can be adjusted to accommodate different lengths. It also houses the tailstock quill, which can be extended or retracted to apply pressure against the workpiece to prevent it from moving during machining. Finally, the cutting tool or tool bit is a replaceable part that is attached to the carriage. It is responsible for removing material from the workpiece to shape it according to the desired specifications.

Summary

An engine lathe is called so because it was originally operated by a steam engine, which powered the machine. This machine was widely used in the 18th and 19th centuries for various machining tasks, such as turning, facing, drilling, and threading. The engine lathe played a crucial role in the development of the Industrial Revolution, allowing for mass production of accurate metal parts.

Over time, the term “engine lathe” became synonymous with any lathe that is powered by an electric motor, rather than a steam engine. This type of lathe continues to be used today in manufacturing industries, enabling the production of precise components for a wide range of products. Understanding the history and significance of the engine lathe helps us appreciate its important role in shaping the way we manufacture goods.