If you’ve ever wondered, “Why doesn’t my bandsaw cut straight?” you’re in the right place! Having trouble achieving those clean, precise cuts with your bandsaw can be frustrating. But fear not, because in this article, we’ll dive into the common reasons behind this issue and discuss ways to fix it. So, let’s get to the root of the problem and straighten things out!

When it comes to bandsaw cutting woes, various factors can throw off its straightness. From blade alignment to improper tensioning, the culprit for the uneven cuts could be hiding in plain sight. But don’t worry, we’ll demystify these problems in a jargon-free way. In no time, you’ll be back on track to effortlessly cutting straight lines with your bandsaw.

Is your bandsaw veering off course and leaving you with wonky cuts? Don’t worry, we’ve got your back. In this article, we’ll walk you through the common culprits behind the lack of straightness in your bandsaw cuts. From choosing the right blade to ensuring proper blade tracking, you’ll soon be on your way to achieving those perfect, precise cuts you’ve been dreaming of. So, let’s roll up our sleeves and discover the secrets to getting your bandsaw back on the straight and narrow!

Why Doesn’t My Bandsaw Cut Straight? Troubleshooting Tips and Solutions

Are you frustrated with your bandsaw’s inability to make clean, straight cuts? Don’t worry, you’re not alone. Bandsaws, like any other woodworking tool, can experience issues that affect their cutting performance. In this article, we will explore the common reasons why your bandsaw might not be cutting straight and provide you with troubleshooting tips and solutions. Whether you’re a woodworking enthusiast or a professional, understanding the causes behind this problem will help you achieve accurate and precise cuts with your bandsaw.

Improper Blade Tension: A Common Culprit

One of the primary reasons why a bandsaw fails to cut straight is improper blade tension. When the blade is not sufficiently tensioned, it can lead to twisting or wandering during the cutting process. Insufficient tension can cause the blade to deflect, resulting in curved or uneven cuts. To resolve this issue, start by checking the tension of your bandsaw blade and adjusting it as necessary. Follow these steps:

- Turn off and unplug your bandsaw for safety.

- Consult your bandsaw’s manual to determine the recommended tension setting for your blade.

- Using the tension adjustment knob or mechanism on your bandsaw, increase or decrease the tension until it matches the recommended setting.

- Check the tension regularly, as it may need to be adjusted over time due to blade wear or other factors.

Once you have properly tensioned your bandsaw blade, you should notice an improvement in the straightness of your cuts. However, if the issue persists, there may be other factors contributing to the problem.

Misaligned Blade Guides: A Hidden Culprit

Another common reason for bandsaw blades not cutting straight is misaligned blade guides. Blade guides are designed to keep the blade straight and stable during cutting. If these guides are not properly aligned, it can cause the blade to deflect and result in curved cuts. Here’s how to check and adjust the blade guides:

- Make sure the bandsaw is turned off and unplugged.

- Inspect the blade guides, both above and below the table, for any signs of misalignment.

- Loosen the locking screws or knobs that secure the guides in place.

- Gently adjust the guides so that they are in line with the blade.

- Tighten the locking screws or knobs to secure the guides in their new position.

- Test the bandsaw by making a straight cut and observe if the blade tracks properly without wandering.

By ensuring that your blade guides are properly aligned, you can eliminate one of the potential causes for your bandsaw not cutting straight. However, if the problem persists, it may be necessary to explore other potential issues.

Dull or Improperly Set Blade: A Cutting Culprit

A dull or improperly set blade can also contribute to a bandsaw’s inability to cut straight. When a blade becomes dull, it can lead to excessive friction and overheating, causing the blade to wander during cutting. Additionally, if the blade is not set correctly, it may not have the desired tooth orientation to make straight cuts. To address these issues, follow the steps below:

- Ensure the bandsaw is turned off and unplugged.

- Inspect the blade for any signs of dullness or damage. Replace the blade if necessary.

- Use a blade setting jig to ensure the teeth are properly set. This will help maintain a consistent cutting angle and improve cutting accuracy.

- Regularly clean and lubricate the blade to reduce friction and prolong its lifespan.

By using a sharp and properly set blade, you can significantly improve the cutting performance of your bandsaw. Remember to always prioritize safety when dealing with blades and consider wearing protective gear, such as gloves and safety glasses.

Other Potential Causes and Additional Tips

While blade tension, misaligned guides, and blade condition are common culprits for a bandsaw not cutting straight, there are other factors to consider. Here are some additional potential causes and tips to help troubleshoot your bandsaw’s cutting issues:

- Table calibration: Ensure that your bandsaw’s table is properly calibrated and adjusted to the desired angle or orientation for making straight cuts.

- Feed rate: Maintain a consistent and appropriate feed rate when guiding your material through the bandsaw to prevent the blade from deflecting.

- Blade tracking: Check the tracking of the blade to ensure it is properly aligned with the wheels and does not drift off course.

- Blade quality: Invest in high-quality blades specifically designed for the type of cutting you intend to perform. Different materials may require different types of blades.

- Workpiece stability: Securely clamp or stabilize your workpiece to prevent movement or vibration during cutting, which can lead to inaccurate cuts.

- Regular maintenance: Keep your bandsaw well-maintained by cleaning it regularly, checking for loose components, and ensuring the motor and wheels are in good working condition.

By considering these additional factors and implementing the corresponding tips, you can enhance the cutting accuracy and performance of your bandsaw. Remember that practice and patience are key to mastering any woodworking tool, including the bandsaw.

Conclusion

Although the reasons for a bandsaw not cutting straight can vary, addressing common issues such as improper blade tension, misaligned blade guides, and blade condition can help significantly improve cutting accuracy. Additionally, considering factors like table calibration, feed rate, blade tracking, blade quality, workpiece stability, and regular maintenance can further enhance the performance of your bandsaw. By troubleshooting and implementing the tips provided in this article, you’ll be well on your way to achieving clean, straight cuts with your bandsaw.

Key Takeaways: Why Doesn’t My Bandsaw Cut Straight?

- A dull blade could be the reason your bandsaw isn’t cutting straight.

- Inaccurate blade tension can cause the bandsaw to veer off course.

- Improper blade tracking may result in crooked cuts.

- The blade guides should be properly aligned for precise cutting.

- Make sure the fence or guide is set up correctly for straight cuts.

Frequently Asked Questions

Here are the most commonly asked questions about bandsaws and why they may not be cutting straight.

1. What are some common reasons why my bandsaw doesn’t cut straight?

There are a few potential reasons for this. One common issue is blade tension. If the blade isn’t adequately tensioned, it can lead to wobbling and inaccurate cuts. Another possibility is blade alignment. If the blade isn’t properly aligned with the saw’s guides, it can cause the cut to veer off course. Finally, dull blades can also contribute to a lack of straight cuts. A dull blade will struggle to cut through the wood cleanly, resulting in a less precise cut.

To troubleshoot these issues, start by checking the blade tension and adjusting it if necessary. Next, ensure that the blade is properly aligned with the guides. Use a straightedge or a specialized tool to align the blade if needed. Lastly, if your blade is dull, it’s time to replace it with a new one. Regularly sharpen or replace blades to maintain clean and accurate cuts.

2. How can I ensure the blade tension on my bandsaw is correct?

The correct blade tension is crucial for straight cuts. One way to check the tension is by plucking the blade. Pluck it like a guitar string, and listen for a clear, high-pitched sound. If the sound is low and dull, the tension may be too loose. Alternatively, if the blade is overly tight, it may produce a high-pitched sound but won’t have any give when pressed with your finger.

Another method is to check the blade deflection. With the bandsaw turned off, press on the blade’s side with your thumb. If the deflection is between 1/4 and 1/2 inch, the tension is likely correct. However, if the deflection is much more or less, it’s a sign that you need to adjust the tension accordingly. Consult your bandsaw’s manual for specific guidelines on adjusting blade tension based on the model you have.

3. What can cause blade misalignment on a bandsaw?

Blade misalignment on a bandsaw can occur due to a few different factors. One possibility is improper guide setup. Bandsaws typically have upper and lower blade guides that help keep the blade aligned. If these guides are not set correctly or if they are worn out, it can cause the blade to veer off course. Another cause of misalignment can be the blade tension adjustment. If the bandsaw’s blade tension is not properly adjusted, it can affect the alignment of the blade.

To address blade misalignment, start by checking and adjusting the blade guides. Make sure they are set up according to the manufacturer’s instructions. If they are worn out, consider replacing them. Additionally, double-check the blade tension to ensure it is correctly adjusted. If you’re unsure about how to properly align the blade or set the tension, refer to your bandsaw’s manual or consult a professional.

4. Can a dull blade be the reason for my bandsaw not cutting straight?

Yes, a dull blade can be a common cause of bandsaws not cutting straight. When a blade is dull, it struggles to make clean and precise cuts through the wood. Instead, it may leave behind rough edges or struggle to cut through the material altogether, resulting in a crooked or uneven cut. Dull blades can also cause increased friction and heat, leading to blade deflection and inaccurate cuts.

If you suspect your blade is dull, it’s crucial to replace it with a new, sharp blade. Most bandsaw blades can be replaced easily, either by the user or by taking the saw to a professional for blade replacement. Regular maintenance, such as sharpening or replacing blades when needed, will help ensure clean and accurate cuts with your bandsaw.

5. Are there any maintenance tips to help my bandsaw cut straight?

Yes, there are several maintenance tips that can help your bandsaw cut straight. Regular blade maintenance is essential. Keep your blades sharp and replace them when they become dull. Clean the bandsaw regularly and remove any debris that may affect the cutting performance. Lubricate the moving parts of the saw to ensure smooth operation. Additionally, periodically check and adjust the blade tension and alignment to ensure optimal cutting accuracy.

It’s also essential to use the correct blade for the task at hand. Different blades are designed for specific types of cuts and materials. Using the right blade for the job will improve cutting performance and accuracy. Finally, regularly inspect your bandsaw for any worn or damaged parts and replace them as needed. Good maintenance practices will help keep your bandsaw in excellent working condition and ensure straight and precise cuts.

Summary

Having trouble with your bandsaw not cutting straight? Here’s what you need to know:

First, check your blade tension and alignment. Make sure it’s tight and centered on the rubber tires. Next, examine the blade for any defects or dullness, and replace if necessary.

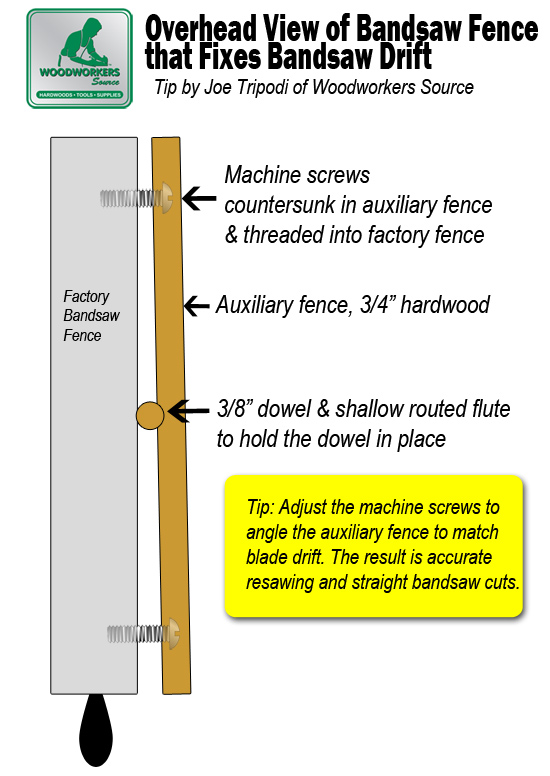

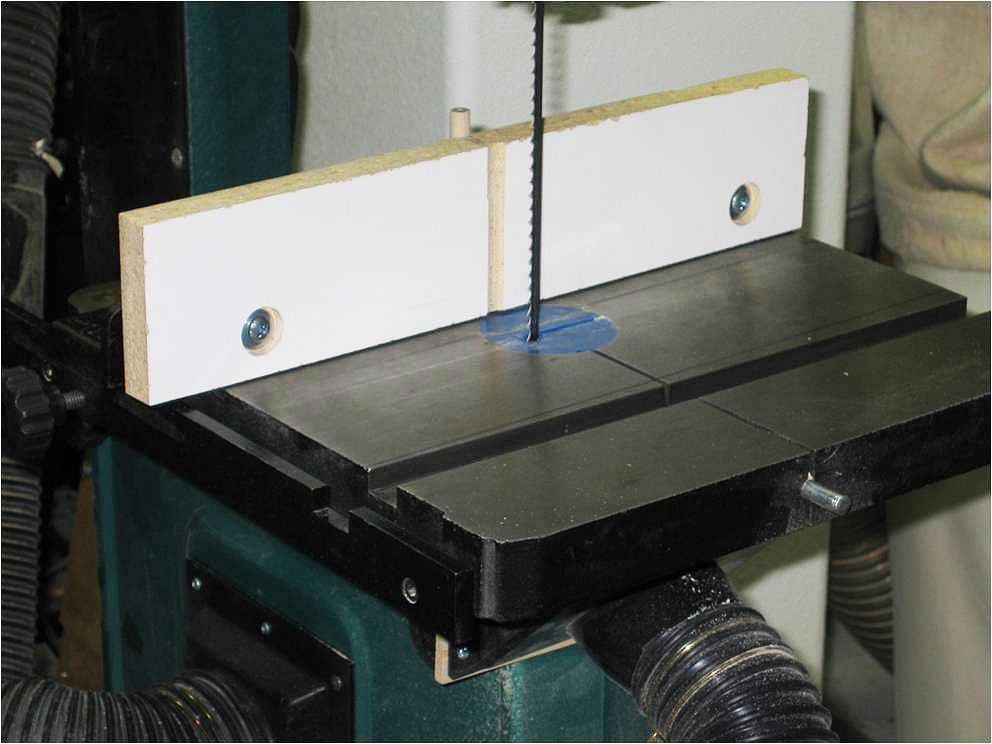

Another common issue is the blade drift, which can be corrected by adjusting the fence or using a drift control device. Remember to go slow and steady when cutting, and let the machine do the work for you.

In conclusion, ensuring proper blade tension, alignment, and addressing blade drift are essential for getting straight cuts with your bandsaw. Happy cutting, and don’t forget to stay safe!