Are you wondering what speed to use on a lathe? Well, you’ve come to the right place! Using the right speed is crucial for a successful turning project. So, let’s dive in and demystify the world of lathe speeds together!

When it comes to using a lathe, finding the right speed is like finding the perfect rhythm for a dance. It’s all about balance and harmony. You don’t want the lathe spinning too fast or too slow – it needs to be just right.

But how do you determine the ideal speed for your lathe? Don’t worry, we’ve got you covered! In this article, we’ll explore the factors that influence your lathe speed decision and provide you with practical tips to help you dial in the perfect speed for your turning needs. So, let’s get ready to spin that lathe and create something amazing!

- Identify the material being turned

- Consult lathe speed reference guides

- Consider the type and size of cutting tool

- Adjust speed for desired finish

Remember, finding the right lathe speed may require experimentation and adjustment for different projects.

What Lathe Speed to Use: A Comprehensive Guide

Welcome to our comprehensive guide on determining the optimal lathe speed for your woodworking projects. When it comes to achieving the best results, the speed at which your lathe spins plays a crucial role. But with so many variables to consider, it can be overwhelming to know exactly what speed to use. In this article, we’ll break down the factors that influence lathe speed and provide you with practical tips to ensure success in your turning projects.

The Importance of Understanding Lathe Speed

Before diving into the specifics, it’s essential to understand why lathe speed is so crucial. The speed determines how quickly or slowly the wood spins on the lathe, directly impacting the cutting action and the quality of the finished piece. Choosing the right speed helps prevent tear-out, promotes smoother cuts, and maximizes control over the turning process.

Several factors influence the ideal lathe speed, including the type of wood, the size and shape of the piece, and the tools being used. By understanding the interplay between these variables, you’ll be able to make informed decisions and achieve excellent results in your woodworking endeavors.

When determining lathe speed, it’s important to strike a balance between safety and efficiency. Running the lathe at excessively high speeds can lead to accidents and excessive wear on the tools. On the other hand, running it too slowly can result in poor cutting performance and prolong the turning process.

Factors Affecting Lathe Speed

Now that we understand the significance of lathe speed let’s delve into the factors that influence the optimal speed for different turning scenarios:

Type of Wood

The type of wood you’re working with plays a crucial role in determining the ideal lathe speed. Softwoods, such as pine or cedar, can be turned at higher speeds compared to hardwoods like oak and maple. Softwoods are less dense and can withstand the higher RPMs without significant tear-out. Hardwoods, however, require slower speeds to achieve clean cuts and prevent splintering.

To determine the best speed for a specific wood species, consider its hardness, density, and grain pattern. Experimentation and experience will eventually guide you to the optimal speed range for each type of wood.

It’s worth noting that certain woods, like burls or spalted wood, contain irregular grain patterns or voids. When working with these materials, it’s crucial to reduce the lathe speed to minimize tear-outs and maintain control over the cutting process.

Size and Shape of the Workpiece

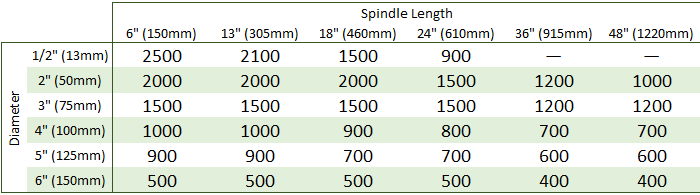

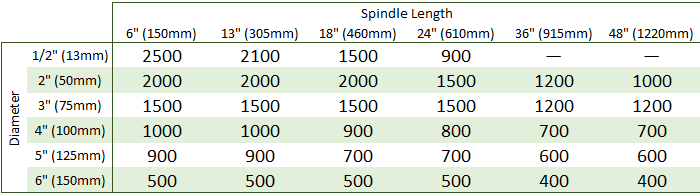

The size and shape of the workpiece directly impact the choice of lathe speed. Generally, larger workpieces require slower speeds compared to smaller ones. This is because larger diameters have a greater circumference, resulting in higher surface speeds when turned at the same RPM as a smaller workpiece.

Additionally, when turning long and slender pieces, such as spindle or pen blanks, it’s advisable to use higher speeds. The centrifugal force generated by the spinning wood helps reduce vibration and improves stability during the turning process.

As a general rule of thumb, start with a slower speed for larger, more massive workpieces and gradually increase it as you progress. Conversely, for smaller or delicate workpieces, begin with a higher speed and adjust as required to achieve the desired results.

Type of Turning Tools

The type of turning tools you use also influences the ideal lathe speed. Each tool is designed to work optimally within a particular RPM range. For instance, gouges and scrapers work well at lower speeds, while spindle roughing gouges and parting tools can tolerate higher speeds.

When using a specific turning tool, refer to the manufacturer’s recommendations for the recommended range of lathe speeds. These suggestions are based on the tool’s design, cutting angle, and the force it applies during the cutting process. Adhering to these guidelines will help ensure better cutting performance, prolong the tool’s lifespan, and prevent accidents.

Remember that the choice of tools and lathe speed go hand in hand. As you acquire more experience and understanding of different tools, you’ll be able to fine-tune the lathe speed to maximize their performance and achieve the desired results.

Practical Tips for Determining Lathe Speed

Now that we’ve explored the factors affecting lathe speed let’s discuss some practical tips to help you determine the optimal RPM for your turning projects:

Experiment and Practice

Since lathe speed depends on various factors, the best way to determine the ideal speed is through experimentation and practice. Start by testing different speeds on scrap wood or less important projects to see how the wood reacts. Take note of the results and adjust accordingly until you achieve the desired outcome. Keep a record of these settings for future reference.

By dedicating time to experimentation, you’ll gain valuable insights into the behavior of different woods and develop an intuition for selecting the right speed for future projects.

As you practice, focus on maintaining proper form, control, and tool presentation for optimal cuts. This will enhance your ability to gauge the effectiveness of different lathe speeds and make more informed decisions during the turning process.

Consult Expert Resources

Take advantage of the wealth of knowledge available from expert woodturners, online forums, books, and videos. Learning from experienced individuals who have faced similar challenges can significantly accelerate your understanding of lathe speeds and help you avoid common pitfalls.

Joining local woodworking clubs or attending workshops and demonstrations can also be invaluable in expanding your knowledge and skill set. These resources often provide hands-on experiences and opportunities to interact with seasoned turners who can offer personalized advice tailored to your specific goals and projects.

Consider the Desired Outcome

When determining lathe speed, always consider the desired outcome of your project. Are you aiming for a smoother finish or focusing on shaping the wood quickly? The intended result should dictate the speed at which you operate the lathe.

For intricate detail work, such as texturing or carving, slower speeds are typically more suitable. On the other hand, when roughing out a blank or creating straight, clean cuts, higher speeds can expedite the process. Keep in mind that achieving the desired outcome may involve adjusting the lathe speed at different stages of the turning process.

In conclusion, understanding and selecting the appropriate lathe speed is essential for achieving optimal results in your woodworking projects. Factors such as the type of wood, size and shape of the workpiece, and the tools being used all play a role in determining the ideal RPM. Through experimentation, practice, and leveraging external resources, you can quickly develop the skills needed to make informed decisions and produce outstanding turning projects.

Key Takeaways: What Lathe Speed to Use?

- Choosing the right lathe speed is crucial for successful turning projects.

- Higher lathe speeds work better for smaller workpieces with fine details.

- Lower lathe speeds are ideal for larger workpieces with rough cuts.

- Experiment with different speeds to find the perfect balance for your project.

- Take into account the type of material you are working with when determining lathe speed.

Frequently Asked Questions

When it comes to using a lathe, understanding the appropriate speed is crucial for achieving optimal results. Here are some commonly asked questions about what lathe speed to use:

1. How do I determine the right speed for my lathe?

The speed at which you should run your lathe depends on various factors such as the material you’re working with, the size of the workpiece, and the type of operation you’re performing. As a general rule of thumb, larger workpieces require slower speeds, while smaller workpieces can handle faster speeds. Additionally, softer materials typically warrant higher speeds, while harder materials are better suited for slower speeds. It’s a good idea to consult the user manual of your lathe or seek guidance from experienced machinists to determine the appropriate speed for your specific situation.

Experimentation and practice are key when determining the right speed for your lathe. Start with a conservative speed and observe the results. If the lathe is producing chatter, rough finishes, or other undesirable outcomes, it’s an indication that you need to adjust the speed accordingly. Gradually increase or decrease the speed until you find the optimal setting that allows for smooth cutting, efficient chip removal, and desired surface finish.

2. Can I use a single speed for all lathe operations?

Using a single speed for all lathe operations is not recommended. Different lathe operations require varying speeds to achieve the best results. For example, roughing out a workpiece may require a faster speed to remove material quickly, while finishing cuts call for slower speeds to achieve a smoother surface. By adjusting the lathe speed based on the specific operation, you can improve the quality and efficiency of your work.

Moreover, using the wrong speed for a particular operation can lead to several issues, including tool wear, poor surface finish, and even damage to the workpiece or lathe itself. To ensure optimal performance and avoid potential problems, it’s crucial to use the appropriate speed for each specific operation you undertake on your lathe.

3. What happens if I use a speed that is too high?

Using a speed that is too high on your lathe can have detrimental effects on both the workpiece and the cutting tools. When the speed is too high, the cutting tools may experience excessive heat, leading to premature dulling or even breakage. The workpiece may also heat up, resulting in thermal expansion and dimensional inaccuracies. Additionally, high speeds can cause vibration, leading to poor surface finishes and reduced tool life.

It’s crucial to ensure that the chosen lathe speed is appropriate for the material, workpiece size, and the specific operation being performed. Adjusting the speed to a lower setting can help mitigate these issues and ensure better machining results.

4. What are the consequences of using a speed that is too low?

Using a speed that is too low can also have negative consequences on your lathe operation. When the speed is too low, the cutting process may become sluggish, resulting in poor chip evacuation. This can lead to clogging of the cutting tool, poor surface finishes, and increased cutting forces. Additionally, a low speed may cause excessive tool pressure, leading to accelerated tool wear and reduced tool life. In some cases, using a low speed on certain materials can even cause work-hardening, making it more difficult to achieve desired machining results.

To avoid these issues, it’s essential to select an appropriate lathe speed based on the factors mentioned earlier. A higher speed may be necessary to ensure efficient chip removal, good surface finish, and prolonged tool life.

5. Can I rely solely on the recommended lathe speed range?

While the recommended lathe speed range provided by the manufacturer serves as a valuable starting point, it’s not the ultimate determinant of the ideal speed for your specific situation. The recommended range accounts for the general characteristics of the lathe and the materials it can handle. However, variations in workpiece size, tooling, and operation requirements necessitate some experimentation and adjustment.

The recommended range typically offers a safe zone for operating the lathe, but optimal performance often lies within a narrower range that suits your specific needs. By considering the factors mentioned earlier, conducting test runs, and making incremental adjustments, you can fine-tune the speed to achieve the best results for your unique lathe projects.

Summary

When using a lathe, the speed you choose depends on the material you’re working with. For harder materials like metal, slower speeds are better to prevent overheating. Softer materials like wood can be turned at higher speeds. It’s important to match the speed to the material to get the best results.

Additionally, the diameter of your workpiece also affects the appropriate lathe speed. Larger diameters require slower speeds to maintain stability, while smaller diameters can handle faster speeds. Remember to always consult the lathe’s manual for recommended speeds and adjust accordingly. By understanding the relationship between material, diameter, and speed, you’ll be able to work with your lathe effectively and safely.